Completed

HOPy – Headstart on pyrolysis

HOPy wants to find a solution that mitigates the environmental impact of plastic waste and taps into its potential as a resource for creating new materials.

Completed

ZERO BRINE

The ZERO BRINE project combines technologies to recover products of high quality and sufficient purity from brine.

ENCORE – nExt geNeration COmpRession hEat pump

This project demonstrates the enhancement of compression heat pump performance by using a pilot scale test unit.

Demonstration Polymer Heat Exchanger

The goal of this project is to demonstrate the innovative technologies as developed by HeatMatrix in the industrial process in the BioMCN factories. On the one hand this would result...

Completed

SAAI – Social Acceptance of AI in Industry

The SAAI project focuses on accelerating the implementation of Artificial Intelligence (AI) in industry, leading to an energy use reduction of 5-40%, an increased competitiveness of industry, and increased economic...

Completed

VERA – Accelerating Energy Transition Realization Approach

The Vera project aims to further develop and implement industrial heat pumps in the Netherlands.

Odysseus

Goal of this project is to develop a library of complementary techniques for concentrating brines beyond reverse osmosis.

Completed

HyScaling – Making better electrolyzers in a better way

HyScaling aims to scale electrolysis capacity up to 5GW by 2030 so the Netherlands can play a key role in the global green hydrogen economy.

Completed

Nanofiltration (EAMS) – Hybrid membranes for organic solvent nanofiltration

Nanofiltration (EAMS) is a project that focusses on finding practical and economical viable membrane materials to be commercially applied.

Completed

CirBind – Circular binder applications

ISPT's Cirbind project scales up the Plantics-GX bioresin production process to generate safe, strong & high impact circular binder applications.

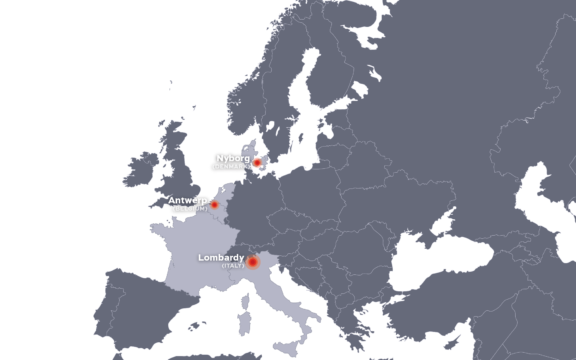

R-ACES – FRamework for Actual Cooperation on Energy on Sites and Parks

R-ACES aims to turn high-potential, high-impact industrial clusters into eco-regions with at least 10% reduction in emissions in smart energy.

Flexible Efficient Electrification of Industrial Heat Cases

This project will develop innovative process designs solving the efficient flexible electrification challenge.

Completed

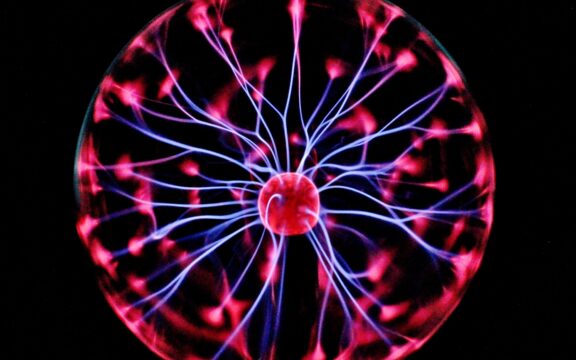

Plasma Conversions

Industrial ammonia production is energy intensive and has a huge footprint. A plasma integrated water electrolyser provides an ecologically clean alternative process to Haber-Bosch.

Aramazing

Aramids hold untapped potential in the journey towards sustainability. We can transform these once-disposed materials into a circular value chain, reducing waste, and striving for CO2 neutrality.

Completed

Biorefinery Program

Biorefinery enables the production of healthy ingredients and the recovery of valuable components (i.e. proteins) out of process streams.

PlastiCycle 4.0 – Revolutionizing smart formulation in mechanical recycling for closing the circular value chain

Transforming plastic waste into high-quality recycled plastics. Discover how PlastiCycle 4.0 is revolutionizing mechanical recycling.

Completed

Cell-U-Value

Cell-U-Value developed and utilized the capabilities of tertiary cellulose as a feedstock for biobased and sustainable chemicals to its fullest potential.

TEXPOWER – Textile Polycotton Waste Evaluation & Recycling

The TEXPOWER project aims to enable a transparent, circular polycotton textile value chain for a sustainable industry in the Netherlands.

DRAGONS Egg – Increasing energy efficiency by steering DRoplet AGglomeratiON in Spray dryers

The DRAGONS Egg-project aims to unravel the dynamics of atomisation behaviour in drying and agglomeration of the droplet.

Completed

InReP – An Integrated approach towards Recycling of Plastics

Recycling plastics is one of the biggest challenges the industry is facing today. This projects aims to overcome current challenges.

Completed

Next Level Solid Oxide Electrolysis

Solid Oxide Electrolysis is a technology with great potential for large-scale green hydrogen production by water electrolysis. This project explores the upscaling potential of SOEC.

EBI – Engineering Business Intelligence

The EBI project uses data collection, data analytics and data visualization to reduce energy usage in existing processes by 5-25%.

Completed

Smart Maintenance Skillslab

In a Smart Maintenance Skillslab industry and educational institutions can collaborate on new forms of education to solve shortage on the labor market.

Completed

COMPRESORP

COMPRESORP focuses on upgrading low temperature waste water streams of separation processes with compression resorption heat pumps.