Completed

HyScaling – Making better electrolyzers in a better way

HyScaling aims to scale electrolysis capacity up to 5GW by 2030 so the Netherlands can play a key role in the global green hydrogen economy.

Completed

Next Level Solid Oxide Electrolysis

Solid Oxide Electrolysis is a technology with great potential for large-scale green hydrogen production by water electrolysis. This project explores the upscaling potential of SOEC.

Completed

PRIDES: Deep Eutectic Solvents in the Paper Industry

The European project cluster aims to approach 80% CO2 emission reduction in the lignocellulose processing chain.

MilDeWat – Breakthrough Mild Dewatering Technologies

This project will enhance the implementation of mild (energy extensive) dewatering technologies to contribute to industry's energy reduction goals.

Completed

Novel Process Routes – Reduction of energy use by novel process routes for food (ProFo)

Several partners are working towards a 50% reduction of energy use developing novel process routes in food processing.

Completed

W2T – Waste2Taste

Waste to Taste is a project about closing the circle in food waste streams using vegetable waste for the production of fully natural food ingredients.

EBI – Engineering Business Intelligence

The EBI project uses data collection, data analytics and data visualization to reduce energy usage in existing processes by 5-25%.

Completed

ZERO BRINE

The ZERO BRINE project combines technologies to recover products of high quality and sufficient purity from brine.

Completed

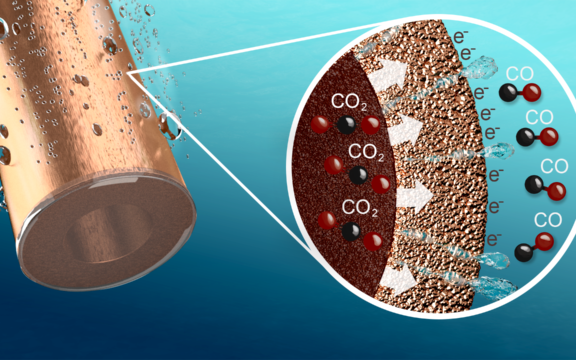

E3C – Electrons to Close the Carbon Cycle

Development and evaluation of tubular and flat porous electrodes for the electrochemical conversion of gasses at ambient temperature. Motivation Renewable electricity (RE) generation is currently growing at a rapid pace....

COSMOS – Organic solvent nanofiltration membranes on low cost ceramic supports

The COSMOS-project found that membrane technology has the potential to replace or supplement current inefficient distillation processes.

TEXPOWER – Textile Polycotton Waste Evaluation & Recycling

The TEXPOWER project aims to enable a transparent, circular polycotton textile value chain for a sustainable industry in the Netherlands.

Completed

Fine Biofuels

In the Netherlands there is a total quantity of 1 million tons of roadside grass which must be mowed at least twice a year to keep the roadside banks safe....

Completed

Hydrohub GigaWatt Scale Electrolyser

We are an important step further towards a Dutch hydrogen economy: the design for an advanced green hydrogen plant at large scale.

Completed

HOPy – Headstart on pyrolysis

HOPy wants to find a solution that mitigates the environmental impact of plastic waste and taps into its potential as a resource for creating new materials.

Completed

ERGO – Energy Reduction by Condition-based Monitoring

Unlocking energy efficiency and fault detection with electrical signal analysis Electric motors and rotating equipment—such as pumps, fans, compressors, and conveyors—consume over 40% of global electricity. However, nearly one-third of...

Completed

Green Hydrogen Inherent Safety Practices on Large Industrial Scale

This project will develop a uniform safety approach and increase awareness of safety for industrial scale electrolysis plants.

BEAP – Bundled Early Adaptor Project

BEAP helps SMEs make contact with industries, localize and develop their technologies to suite the specific needs of Dutch industrial partners.

New

Advanced Carbohydrates Biorefinery: From Waste to Value

Every year, large amounts of tertiary cellulose end up being incinerated. This results in unnecessary CO₂ emissions and loss of valuable material. The ACB project develops an alternative route: one...

Hydrohub MegaWatt Test Center

This project covers the design, realization and exploration of the Hydrohub MegaWatt Test Center at the Zernike Campus in Groningen.

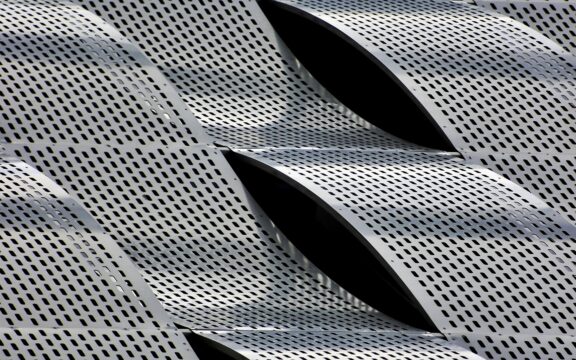

CALMEM – Ceramic atomic layer deposited Nanofiltration membranes for separation of challenging industrial streams

Calmem concerns nano manufactured ceramic membranes that can supersede distillation columns for energy saving in the Netherlands.

Completed

S2C – Steel2Chemicals

The project Steel2Chemicals develops a closed value chain in which CO from steel production is used as feedstock for the chemical industry.

Completed

Probiotics – Low energy living bacterial food formulations

Research towards a novel and generic strategy for probiotics in low energy living bacterial food formulations

Completed

Biorefinery Program

Biorefinery enables the production of healthy ingredients and the recovery of valuable components (i.e. proteins) out of process streams.

Cell-U-Value

Cell-U-Value developed and utilized the capabilities of tertiary cellulose as a feedstock for biobased and sustainable chemicals to its fullest potential.