Completed

Thin Film Drying

A part of the drying and dewattering program with Thin Film Drying as a new technology for product quality and energy consumption

ReSolve – Re-use of industrial solvent process streams

Ceramic organic solvent nanofiltration membranes with small pore sizes and high throughputs, as compared to polymeric membranes, will be developed by a novel technology.

LESSON – Oil free compressor for ammonia based high temperature heat pumps

Wet compression allows for close to isothermal conditions during compression resulting in higher compression isentropic efficiencies. It further prevents operation in the superheating zone of the working fluids of heat...

Completed

INSPEC – Integrating sensor based process monitoring and advanced process control

INSPEC quantitatively integrates information from state-of-the-art Process Analytical Technology, process measurements and dynamic process models (data driven or physics-based) into Advanced Process Control. This will induce a step-change with respect to...

The Heat Is On

The Heat is On aims to make processes for dewatering, drying and heat integration more efficient.

Completed

RMZD – Radial Multi-Zone Drying

The Radial Multi-zone Dryer (RMD) project investigates new type of spray dryer for premium product properties and low specific energy consumption.

Completed

ERGO – Energy Reduction by Condition-based Monitoring

Unlocking energy efficiency and fault detection with electrical signal analysis Electric motors and rotating equipment—such as pumps, fans, compressors, and conveyors—consume over 40% of global electricity. However, nearly one-third of...

EPRoTrans – Energy reduction technologies enabling PRotein Transition

Project Energy Efficient Protein Transition (EProTrans) investigates the processing of several mixed plant-based streams to produce plant-based proteins.

Completed

Scissors – Super Critical Industrial Solution for Suspended Organic Residual Streams

Scissors researches the processing of specific wet waste streams through the potential of super critical water (SCW) technology.

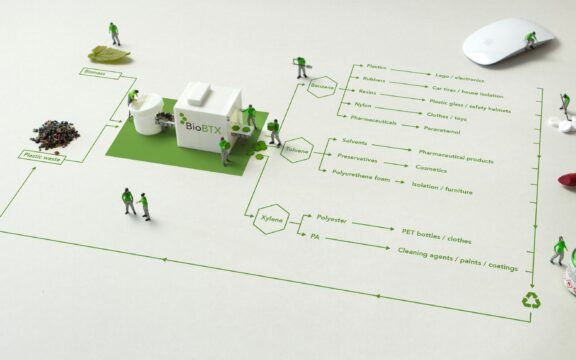

Circular Aromatics – Turning Waste into High-Value Circular Plastics

As the world moves toward net-zero carbon goals, the demand for sustainable materials is rapidly increasing. Plastics, essential in countless applications, must evolve to meet the demands of a circular,...

Completed

EAMS – Energy efficient Affinity-driven Molecular Separation

The aim of the EAMS project is to: Application New or improved affinity separation options for selected cases: extractive distillation and (reactive) liquid-liquid extraction.

Completed

AIDA – Accelerate the Integration of Digitalisation Acceptation

The AIDA project performs research towards predictive capabilities and integration of digital technologies at the various levels of individual processes.

Completed

COSMOS – Organic solvent nanofiltration membranes on low cost ceramic supports

The COSMOS-project found that membrane technology has the potential to replace or supplement current inefficient distillation processes.

Completed

GreenWedge

The GreenWedge project helps SMEs actively market their sustainable technology.

ENCORE – nExt geNeration COmpRession hEat pump

This project demonstrates the enhancement of compression heat pump performance by using a pilot scale test unit.

Completed

PTTP – Process Technology Talent Program

PTTP was a talent program for promising HBO students who aim to drive sustainability in the process technology.

Completed

SiC – Silicon Carbide membranes for innovative oil-in-water separations

This project investigates the behavior of silicon carbide membranes in pilot trials. These determine fouling, cleaning options, cleaning frequency and the consequences for the long term performance and economics. Test...

Completed

Single Droplet Modelling

Multicomponent analysis of single droplet spray drying techniques and PhD research for the drying and dewatering program of ISPT.

Completed

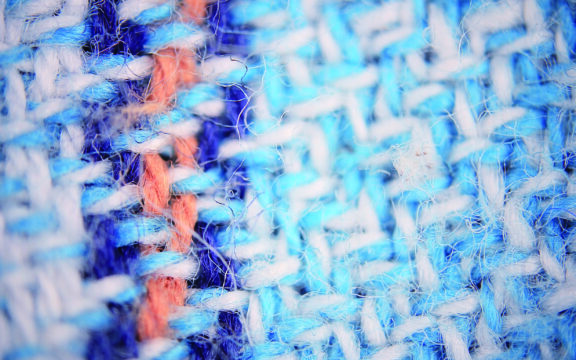

ECWRTI – Electrocoagulation for Water Recycling in Textile Industry

The ECWRTI project is about closing the waterloop in the textile industry.

FLEXSTEAM – Development of heat storage for industrial steam

The FLEXSTEAM project aims to improve the way we can store and re-use thermal energy by using so called ‘Phase Changing Materials’ (PCMs). To achieve a fully circular economy we...

Completed

ZERO BRINE

The ZERO BRINE project combines technologies to recover products of high quality and sufficient purity from brine.

BEAP – Bundled Early Adaptor Project

BEAP helps SMEs make contact with industries, localize and develop their technologies to suite the specific needs of Dutch industrial partners.

Completed

Steam and condensate quality

This project focuses on requiering better insights into the distribution and behaviour of conditioning chemicals that is used in their steam-water cycles and condensate polishing. Process industries strive for more...

DRAGONS Egg – Increasing energy efficiency by steering DRoplet AGglomeratiON in Spray dryers

The DRAGONS Egg-project aims to unravel the dynamics of atomisation behaviour in drying and agglomeration of the droplet.