Electrification of heat-driven processes is needed for a substantial reduction of CO2 emissions. However, the challenge is to efficiently move to full electrification while coping with the high variability of the availability and price of electricity. Additionally, there is the co-existence of natural gas boilers and grid connection limitations. This project will develop potential routes based on available technologies through two virtual public simulation cases. These simulationas will enable partners to share and promote their expertise without having to disclose confidential information.

In short:

- This project will develop innovative process designs solving the efficient flexible electrification challenge

- The designs are simulated through two distinct virtual cases: agro-food and chemicals, allowing for open innovation

- The industry, technology suppliers and technology experts participate by sharing their knowledge and expertise

- Increased efficiency in flexible electrification of heat-driven processes saves substantial amounts of energy. This contributes to a CO2-neutral industrial heat system

The impact of efficient and flexible electrification

Large-scale electrification of industry is necessary for achieving CO2 reduction and gas dependency reduction. However, moving towards full electrification, while natural gas boilers still co-exist and grid connections are limited, is challenging. Moreover, companies struggle with the high variability and price of electricity.

The development of collaborative insights that can help to overcome these challenges usually requires the disclosure of confidential process information. For this reason, the Flexible Efficient Electrification of Industrial Heat Cases project develops two different simulations that will allow companies to share their insights into the specific challenges of industrial heat driven processes, without having to share company specific confidential information. This open innovation concept also allows technology suppliers to cooperate and communicate about concrete solutions for realistic and recognizable industrial processes. Through the project, the industry gets insights in potential combinations of available technologies to solve the challenges in their own heat-driven processes to achieve efficient and flexible electrification. This will stimulate a CO2-neutral industrial heat system.

Two virtual cases

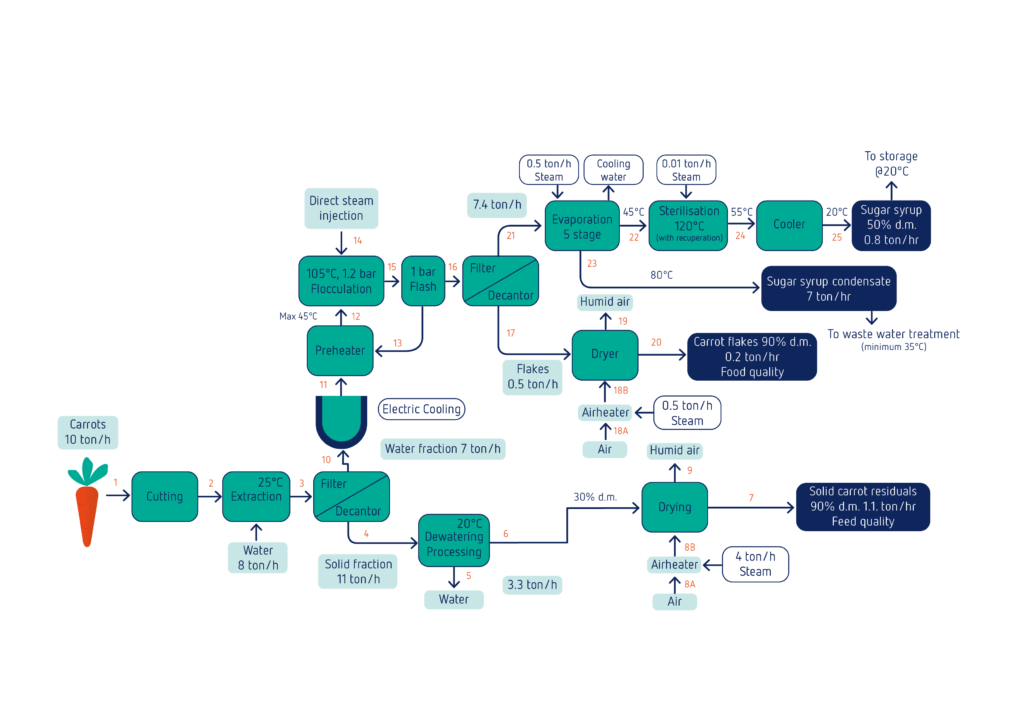

The aim of the project is to develop innovative process designs solving the efficient flexible electrification challenge of the agro-food and chemical industry processes.

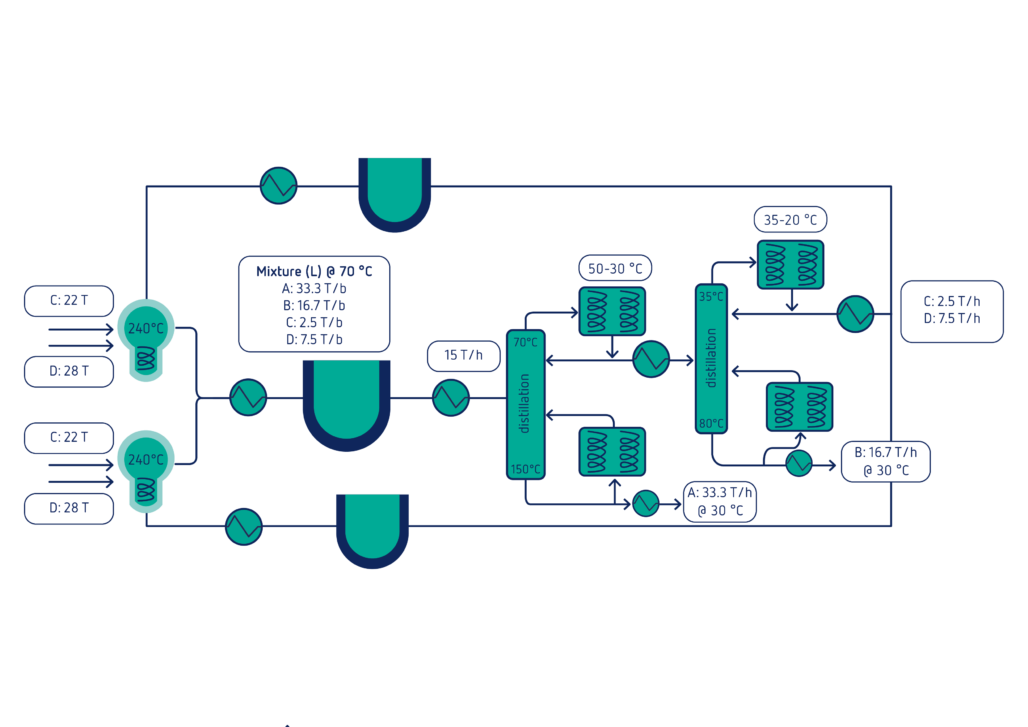

Together with FME, ISPT has set up two realistic virtual cases. These cases are meant as inspirational realistic examples for all industries. They include the most relevant heat-related unit operations of an agro-food and chemical production process. By setting up these cases virtually, it is possible to share information and data on unit operations and possible smart solutions for electrification, even when these solutions are at the heart of the production process.

The activities

Throughout this initiative the consortium will focus on:

- Joint development between process industry and technology suppliers on two real public cases. This collaboration includes the development of possible process designs with new technologies for renewable energy, electrification, and energy storage.

- Communication and dissemination through open publications and regular joint physical meetings with the consortium. The aim is to present and discuss interim results and potential solutions from external organizations or student groups.

The expected results

Through a series of in-depth meetings on each case, the industry (agro-food and chemicals), technology suppliers, and technology experts work together to develop innovative solutions. They will approach the cases from different angles, perspectives and conditions. The solutions incorporate technologies that are, or will soon be, available. Moreover, various challenges are considered, such as: transition to zero-emission, integration into congested grid, growing supply of renewables, local restrictions or opportunities.

Potential elements of these solutions include hybridisation, temporary scaling down of processes in times of shortage, energy storage to capture the surpluses, local renewable energy generation and heat pumps for efficient electrification of heat driven processes.

Also interesting to read

- The Heat is On!

- This project is part of the Heat Integration Platform

You might also be interested in

Acknowledgement & partners