Completed

RiConfigure

RiConfigure is about involving a diverse group of actors in society’s innovation team.

Completed

Preciouspitation

Obtaining process water out of rain from own roof with high energy saving potential compared to current processes. Motivation and Scope Rainwater is already chemically very pure. Only some evaporated...

Completed

Methanol, the LOGIC Choice!

The LOGIC project scales-up the Liquid-Out Gas-In Concept reactor for methanol synthesis from CO2 and sustainable hydrogen.

Completed

IMPACCT – Improved process performance by process intensification in centrifugal contactors

Centrifugal contactors, such as RPBs, could provide significant improvement of separation processes in the chemical industry. This technology seems potentially suitable for replacing or debottlenecking current unit operations which suffer...

Completed

InReP – An Integrated approach towards Recycling of Plastics

Recycling plastics is one of the biggest challenges the industry is facing today. This projects aims to overcome current challenges.

Completed

COLFILM – Collapsing Films in Emulsions

In this project computer simulations are used to reveal the impact of a crucial underlying phenomenon: little waves on the surface of droplets that can suddenly grow and thus accelerate...

Completed

ADVANCED PROCESS CONTROL for dynamic operation of a large-scale test electrolyser

In this project we will researching and modelling the impact of variable operation on large-scale test electrolyser performance in green hydrogen.

GAMBA – Green Alloys Modelling Better Approaches

The GAMBA project seeks to reduce the carbon footprint of the iron and steel industry by transitioning from natural gas to hydrogen-based direct reduction (DRI) processes.

ELSA – Electrically Switchable Affinity Separation Processes

Exploring the advantages of Electrically Switchable Adsorption (ELSA) membranes in the industrial separation process.

Odysseus

Goal of this project is to develop a library of complementary techniques for concentrating brines beyond reverse osmosis.

PlastiCycle 4.0 – Revolutionizing smart formulation in mechanical recycling for closing the circular value chain

Transforming plastic waste into high-quality recycled plastics. Discover how PlastiCycle 4.0 is revolutionizing mechanical recycling.

ReValue – Recovery of Valuable minerals with hybrid ceramic membrane crystallization

The ReValue project explores the potential of membrane crystallization, a promising technology to recover valuable compounds from aqueous streams.

Completed

IMPROVISE – Improved process operation via rigorous simulation models

Improved daily operations of important chemical processes in the Dutch chemical industry through operation technology based on detailed physical models. Incentive Being able to anticipate what a chemical process is...

Recircanol: Circular recovery of ethanol from alkaline-ethanol media at high pH using membrane technology

This project develops nanofiltration membranes and membrane modules for alkaline-alcohol media at high pH for the purification of ethanol and caustic.

Completed

EAMS – Energy efficient Affinity-driven Molecular Separation

The aim of the EAMS project is to: Application New or improved affinity separation options for selected cases: extractive distillation and (reactive) liquid-liquid extraction.

COMTA – COMpact modular Thermo Acoustic heat pump

To further develop the compact electrically driven thermoacoustic heat (TA) pump technology and to prepare for technical demonstration on full scale. The industry is a large consumer of energy and...

BEAP – Bundled Early Adaptor Project

BEAP helps SMEs make contact with industries, localize and develop their technologies to suite the specific needs of Dutch industrial partners.

FOMM – Forward Osmosis Membrane and Module development

Forward osmosis (FO) is a technology recently developed on academic level, with very few example applications in the market, despite its strong benefits. FO is an energy efficient and effective...

Advanced Carbohydrates Biorefinery: From Waste to Value

Every year, large amounts of tertiary cellulose end up being incinerated. This results in unnecessary CO₂ emissions and loss of valuable material. The ACB project develops an alternative route: one...

Completed

Probiotics – Low energy living bacterial food formulations

Research towards a novel and generic strategy for probiotics in low energy living bacterial food formulations

EBI – Engineering Business Intelligence

The EBI project uses data collection, data analytics and data visualization to reduce energy usage in existing processes by 5-25%.

Completed

LEMPLAR – Losses & Emissions in Plastic Recycling

The plastic recycling process today has losses and emissions, such as microplastics, inks and incorrectly sorted plastics. This prevents us of closing the plastic cycle.

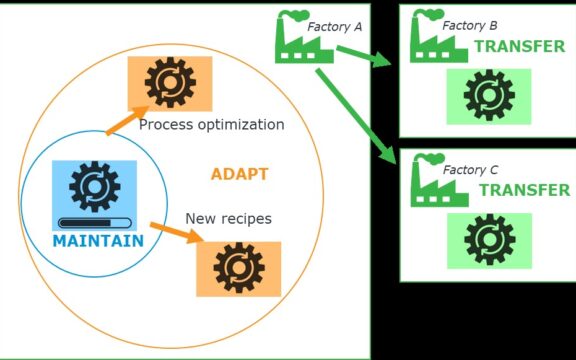

CareFree Models for real-time decision-making

Carefree Models puts process model maintenance, adaptation and transfer into an integrated, automated, and predictive framework that quantifies and reduces the overall resources required to sustain process predictivity and resulting...

Completed

Next Level Solid Oxide Electrolysis

Solid Oxide Electrolysis is a technology with great potential for large-scale green hydrogen production by water electrolysis. This project explores the upscaling potential of SOEC.