ReValue – Recovery of Valuable minerals with hybrid ceramic membrane crystallization

The ReValue project explores the potential of membrane crystallization, a promising technology to recover valuable compounds from aqueous streams.

STARBATCH- Sodium Tetra chloro Aluminate Recyclable BATtery CHemicals

Storage of electricity will play a major role in the energy transition. Lithium-based batteries are now being produced on a large scale, but require expensive resources that are not widely...

Cascade Recyling of Plastic Film (CaRP)

The CaRP project will find and show realistic cascade recycling routes for packaging film waste to minimise the amount of plastic film waste that is incinerated and to maximise the...

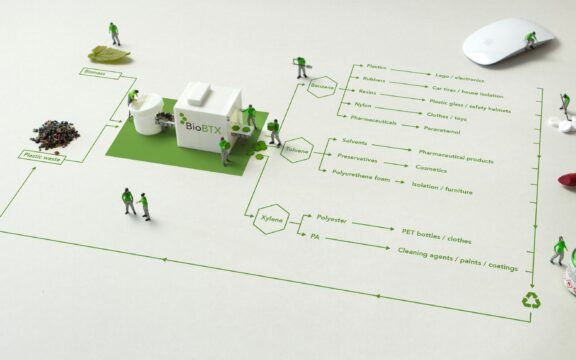

Circular Aromatics – Turning Waste into High-Value Circular Plastics

As the world moves toward net-zero carbon goals, the demand for sustainable materials is rapidly increasing. Plastics, essential in countless applications, must evolve to meet the demands of a circular,...

Advanced Carbohydrates Biorefinery: From Waste to Value

Every year, large amounts of tertiary cellulose end up being incinerated. This results in unnecessary CO₂ emissions and loss of valuable material. The ACB project develops an alternative route: one...