Completed

Preciouspitation

Obtaining process water out of rain from own roof with high energy saving potential compared to current processes. Motivation and Scope Rainwater is already chemically very pure. Only some evaporated...

PoSiMem – Periodic organosilica nanofiltration membranes

This project aims to develop robust, reproducible and easy to scale-up approaches for the production of novel nanofiltration (NF) membranes.

ELSA – Electrically Switchable Affinity Separation Processes

Exploring the advantages of Electrically Switchable Adsorption (ELSA) membranes in the industrial separation process.

Completed

TENMIP – Testing and evaluation of nanofiltration membranes in industrial processes

Make very tight, low swelling NF or RO membranes for organic solvents, test them in process mixtures as present in industry and demonstrate / evaluate their economic feasibility on small...

New

RePlaCE – Recycling of Plastics from Cars and Electronic Equipment

In this project we accelerate recycling of high‑quality engineering plastics from cars and electronic equipment.

Completed

PROVE IT

PROVE IT is all about the technical feasibility of the production of methanol from CO2 waste gas.

Renewable Building Blocks from Complex and wet waste Streams (ReBBloCS)

The ReBBloCS project aims to develop new circular value chains for the valorisation of complex and mixed waste streams into valuable chemical products.

Advanced Carbohydrates Biorefinery: From Waste to Value

Every year, large amounts of tertiary cellulose end up being incinerated. This results in unnecessary CO₂ emissions and loss of valuable material. The ACB project develops an alternative route: one...

Completed

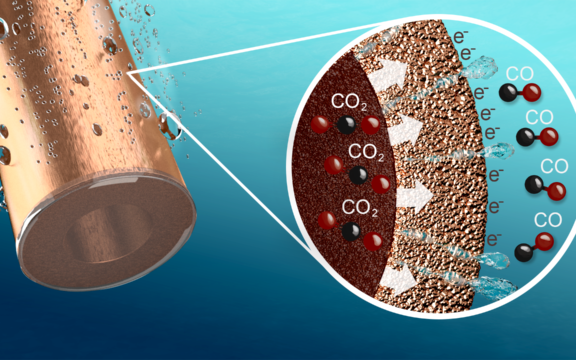

E3C – Electrons to Close the Carbon Cycle

Development and evaluation of tubular and flat porous electrodes for the electrochemical conversion of gasses at ambient temperature. Motivation Renewable electricity (RE) generation is currently growing at a rapid pace....

Completed

Ammonia Pipeline Safety

The Clean Ammonia Platform is doing a study on safety design and risk impact of ammonia pipelines to explore ways to safely transport large volumes of ammonia by pipeline in...

PlastiCycle 4.0 – Revolutionizing smart formulation in mechanical recycling for closing the circular value chain

Transforming plastic waste into high-quality recycled plastics. Discover how PlastiCycle 4.0 is revolutionizing mechanical recycling.

CRUISE – Cost Reduction Industrial Heatpumps

CRUISE project aims to develop 50% less expensive heat pump technology that generates heat in an economically feasible way

Completed

COLFILM – Collapsing Films in Emulsions

In this project computer simulations are used to reveal the impact of a crucial underlying phenomenon: little waves on the surface of droplets that can suddenly grow and thus accelerate...

Completed

WeCare – We Create Awareness & Reduce Energy

The WeCARE project demonstrated the possibilities of Artificial Intelligence technology of EnergQ at a selected number of end users. EnerGQ’s self-learning energy management technology unveiled the excessive energy consumption and with that...

Completed

Sussic – Sustainable treatment of industrial streams

In the Sussic project, atomic layer deposition (ALD) will be used for the development of SiC NF membranes, allowing treatment of challenging industrial streams.

LESSON – Oil free compressor for ammonia based high temperature heat pumps

Wet compression allows for close to isothermal conditions during compression resulting in higher compression isentropic efficiencies. It further prevents operation in the superheating zone of the working fluids of heat...

STARBATCH- Sodium Tetra chloro Aluminate Recyclable BATtery CHemicals

Storage of electricity will play a major role in the energy transition. Lithium-based batteries are now being produced on a large scale, but require expensive resources that are not widely...

SPOT: Sustainable PrOcess heaTing

SPOT (Sustainable PrOcess) aims to reduce the use of fossil energy use for industrial heat with at least 100 PJ/year in 2030.

Completed

IMPACCT – Improved process performance by process intensification in centrifugal contactors

Centrifugal contactors, such as RPBs, could provide significant improvement of separation processes in the chemical industry. This technology seems potentially suitable for replacing or debottlenecking current unit operations which suffer...

Completed

BRECSIT – Bio-based REsin CompoSIte Technologies

Plantics-GX composites can replace conventional, fossil-based plastic composites.

Completed

Thin Film Drying

A part of the drying and dewattering program with Thin Film Drying as a new technology for product quality and energy consumption

DRAGONS Egg – Increasing energy efficiency by steering DRoplet AGglomeratiON in Spray dryers

The DRAGONS Egg-project aims to unravel the dynamics of atomisation behaviour in drying and agglomeration of the droplet.

Completed

GreenWedge

The GreenWedge project helps SMEs actively market their sustainable technology.

FLEXSTEAM – Development of heat storage for industrial steam

The FLEXSTEAM project aims to improve the way we can store and re-use thermal energy by using so called ‘Phase Changing Materials’ (PCMs). To achieve a fully circular economy we...