This hydrogen safety project aimed to develop recommendations for standardisation, meeting process safety requirements for large scale water electrolysis. This is an important step to enable a safe, integrated hydrogen-based energy transition. What makes this safety project rather unique is that it brings together parties with completely different roles in the Green Hydrogen supply chain. From original equipment manufacturers (OEM) to owner-operators and the Royal Netherlands Standardization Institute NEN.

In short:

- H2-Safety2 is a follow-up of the ISPT project Green Hydrogen Inherent Safety Practices on large industrial scale

- There is still limited experience with large-scale water electrolysis

- Integration of process safety aspects in existing or new standards is crucial to enable the expansion of green hydrogen economy

- This project aimed to develop minimum safety requirements and recommendations for standardisation

Creating safety standards for green hydrogen production

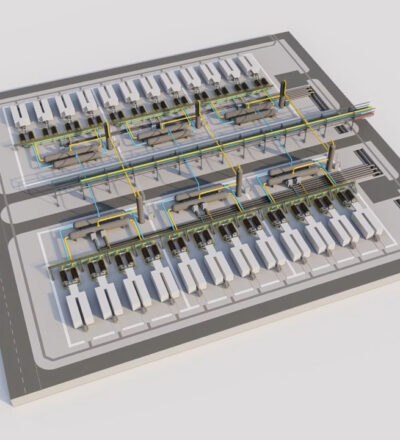

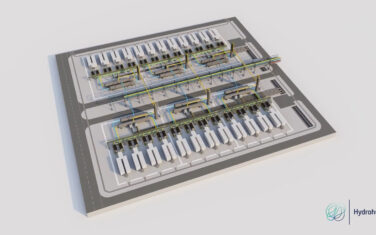

Large scale green hydrogen production by water electrolysis is one of the important solutions towards the energy transition to meet the climate goals. Today, industries have a lot of experience and expertise in process safety of fossil-based hydrogen production, but lack operation and maintenance experience with water electrolysis. Contrary, suppliers (OEMs) know how to design and manufacture electrolysers, but have limited expertise and experience with process safety. A better understanding of process safety aspects, materialised in concrete minimum safety requirements and guidelines is needed to ensure safe design, operation and maintenance of electrolysers.

Accelerate the green hydrogen economy

This project aimed to develop minimum safety requirements and recommendations for standardisation. In addition, the project partners also wanted to achieve a mutual understanding of process safety aspects between technology providers of electrolyser systems, EPC contractors, authorities and owners / operators. This is a prerequisite for the design, implementation, operation and maintenance of large-scale electrolysis systems for the production of green hydrogen. As a consequence, it will be possible to meet the energy transition challenges and accelerate the green hydrogen economy.

Project goals

The project goals were as follows:

- Achieve an understanding of credible hazard scenarios for electrolysers;

- Develop, align and improve alignment of permitting, user and supplier requirements on process safety;

- Prepare new guidelines and practices including industry wide minimum safety requirements;

- Provide technical recommendations and recommendations for best practice for process safety management and risk assessment to a normalization institute with the aim of achieving standardization for industrial electrolyzers.

Project results

The project resulted in a detailed report on the technical safety risks, scenarios and design implications for electrolysis. The results of this project have been presented to the Netherlands Standardization Institute(NEN) and is used for the development of a dedicated National Technical Agreement (NTA).

To complement the report, we have recorded an expert webinar to share key findings, practical examples and insights on next steps.

You might also be interested in

Acknowledgement & partners

This project is co-funded by TKI-E&I with the supplementary grant 'TKI- Toeslag' for Topconsortia for Knowledge and Innovation (TKI’s) of the Ministry of Economic Affairs and Climate Policy.