Completed

COMPACT – Pulsed Compression II

The goal of this project was to produce ethylene from methane using pulsed compression technology and to determine the feasibility for industrial applications.

Completed

ISRO – Implementation of Solvent Recovery in edible Oil

The ISRO project delivers a proof-of-principle of organic solvent nanofiltration-based solvent recovery for two cases. The first case is an integration of OSN with the current distillation process at IOI...

Completed

Amazing – Additive Manufacturing for Zero-Emission Innovative Green Chemistry

Amazing is about replacing large-scale high-temperature cracking processes with electrically driven thermocatalytic dehydrogenation.

Hydrohub MegaWatt Test Center

This project covers the design, realization and exploration of the Hydrohub MegaWatt Test Center at the Zernike Campus in Groningen.

Completed

CALMEM – Ceramic atomic layer deposited Nanofiltration membranes for separation of challenging industrial streams

Calmem concerns nano manufactured ceramic membranes that can supersede distillation columns for energy saving in the Netherlands.

Completed

Cell-U-Value

Cell-U-Value developed and utilized the capabilities of tertiary cellulose as a feedstock for biobased and sustainable chemicals to its fullest potential.

Completed

COMPRESORP

COMPRESORP focuses on upgrading low temperature waste water streams of separation processes with compression resorption heat pumps.

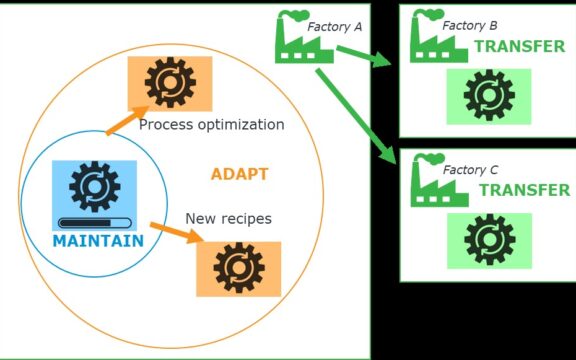

CareFree Models for real-time decision-making

Carefree Models puts process model maintenance, adaptation and transfer into an integrated, automated, and predictive framework that quantifies and reduces the overall resources required to sustain process predictivity and resulting...

Completed

Fine Biofuels

In the Netherlands there is a total quantity of 1 million tons of roadside grass which must be mowed at least twice a year to keep the roadside banks safe....

New

HP4INDUSTRY – Enhance collaboration between industry and heat pump stakeholders

The HP4INDUSTRY project pairs ambitious climate targets with concrete, replicable process integrated solutions for industrial heating and cooling, enabling cleaner, competitive manufacturing for Europe’s future.

Completed

SUPP – Steel Slag Upgrading and PCC Production

The aim of the SUPP project is to create one combined and integrated robust batch process in order to stabilize and upgrade steel slag and neutralize hydrochloric acid. In addition, it...

Completed

HyChain – Energy Carriers and Hydrogen Supply Chain

The HyChain project is focused on a strategic understanding of the drivers behind global emergence of future renewable hydrogen value chains.

Cascade Recyling of Plastic Film (CaRP)

The CaRP project will find and show realistic cascade recycling routes for packaging film waste to minimise the amount of plastic film waste that is incinerated and to maximise the...

MilDeWat – Breakthrough Mild Dewatering Technologies

This project will enhance the implementation of mild (energy extensive) dewatering technologies to contribute to industry's energy reduction goals.

Completed

PTTP – Process Technology Talent Program

PTTP was a talent program for promising HBO students who aim to drive sustainability in the process technology.

COMTA – COMpact modular Thermo Acoustic heat pump

To further develop the compact electrically driven thermoacoustic heat (TA) pump technology and to prepare for technical demonstration on full scale. The industry is a large consumer of energy and...

AutoPlastic: Shaping the Future of Automotive and Plastic Recycling

As the automotive industry faces new recycling legislation, the AutoPlastic project leads the way in boosting car plastic recycling. It helps the Dutch automotive sector stay ahead by developing solutions...

BEAP – Bundled Early Adaptor Project

BEAP helps SMEs make contact with industries, localize and develop their technologies to suite the specific needs of Dutch industrial partners.

Completed

Measurements 4 Management

Measurement 4 Management (M4M) focused on applying data-driven decision-making in the process industry, by combining artificial intelligence (AI) with the domain knowledge of process engineers.

Completed

Sussic – Sustainable treatment of industrial streams

In the Sussic project, atomic layer deposition (ALD) will be used for the development of SiC NF membranes, allowing treatment of challenging industrial streams.

Completed

Engender: Compact Energy Efficient Dryer

Engender works on an energy efficient drying method of foods. Expected energy savings are estimated up to 30%.

DRAGONS Egg – Increasing energy efficiency by steering DRoplet AGglomeratiON in Spray dryers

The DRAGONS Egg-project aims to unravel the dynamics of atomisation behaviour in drying and agglomeration of the droplet.

Completed

MPPS – Multipurpose Plastic Sorting

This project focuses on radically innovating the way we address mechanical sorting of plastic waste.

Completed

RFS – Radio Frequent Sterilization

Heating with Radio Frequent Sterilization (RFS) has large advantages for the product quality.