Sustainable food and biobased processing can only be realised by replacing our current evaporative dewatering processes by processes using more effective driving forces. The aim of the ELECTRIFIED project is to establish new technologies for future key technologies for biomass dewatering, that will allow the Dutch food and biobased industry to lead Europe and the world in better sustainability.

The ELECTRIFIED-project is coordinated by Wageningen University & Research. The consortium exsists of 5 technical Dutch universities and 8 companies, of which 6 end users and 2 equipment suppliers. The Institute for Sustainable Process Technology (ISPT) will disseminate the public results arising from this project, together with the Next Food Collective and NWGD.

Please visit the NWO-LinkedIn for information on results arising from the research activities.

In short:

- Use of electricity as new driving force allows to more efficiently remove water from biomass, in liquid, semi-solid

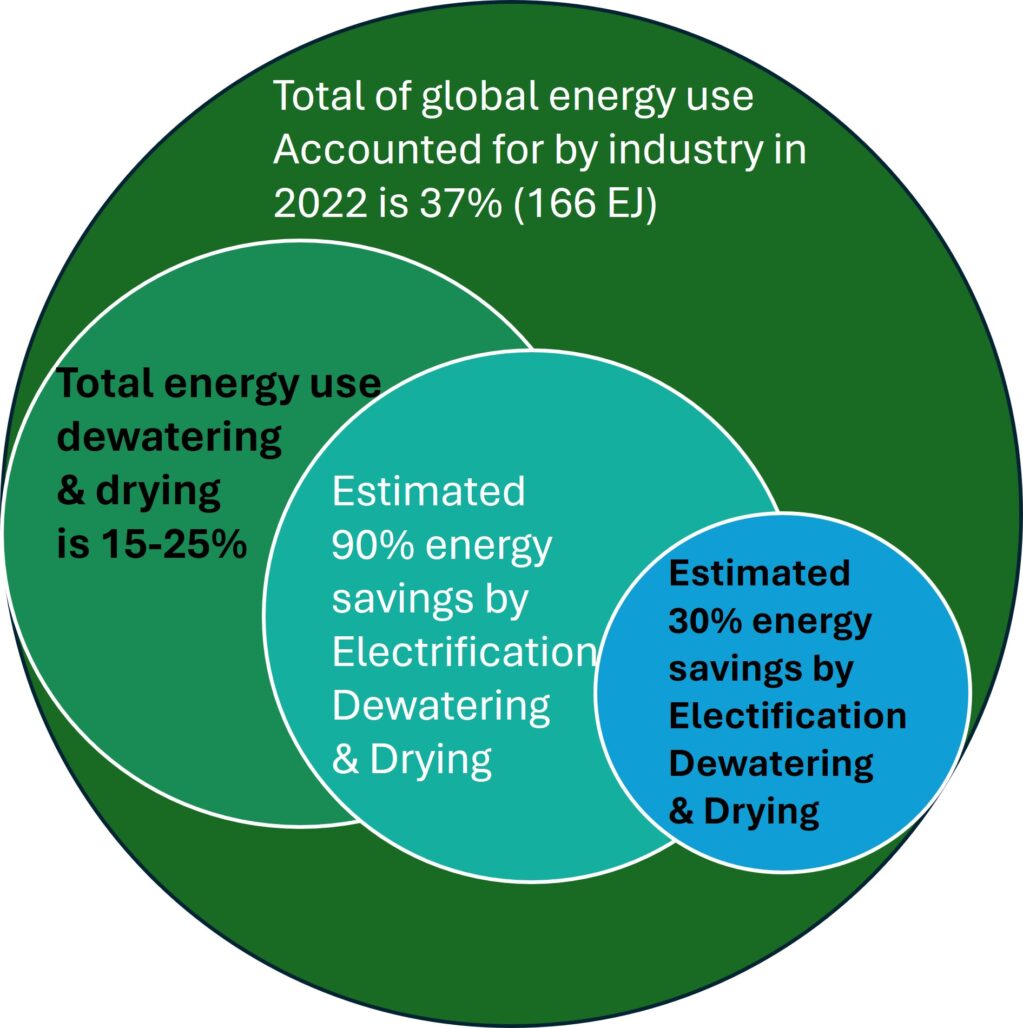

and solid form. - About 30 – 90% of the energy currently required for evaporative dewatering and drying may be saved following

this approach. - Electrification contributes to a lower processing temperatures and thus leads to milder conditions, which can enhance

the quality of the dried products.

Diagram: Total energy use for Dewatering and Drying by Industy* (Food, Paper, Pharma) is 15-25% of total energy use. Estimated energy savings by Electrification is 30-90% for Dewatering and Drying; * https://www.iea.org/energy-system/industry; 2022

Aim: future technologies for biomass dewatering

The aim of the Electrified project is to establish future key technologies for biomass dewatering, that will allow the Dutch food and biobased industry to lead Europe and the world in better sustainability.

Electrically Driven Non-Thermal Dewatering

Drying alone represents around 15-25% of all energy used in the processing industry in the developed world, which is likely to become much more with increasing use of biomass. Sustainable food and biobased processing can only be realised by replacing our current evaporative dewatering processes by processes using more effective driving forces.

ELECTRIFIED uses electric driving forces to extract water from biomaterials, mostly in liquid form. This is done by developing three technologies based on molecularly designed electroresponsive hydrogels, well-controlled electro-osmosis and electrohydrodynamic drying. A wide consortium ensures the practical relevance of the technologies.

Water removal by renewable energy with strong energy reduction

This project will develop the technological principles for enabling strong energy reduction for water removal and drying for foods and biobased materials: Many new resources (e.g., algae but basically many biobased materials) will become only viable when more efficient dewatering technologies become available. Water removal is now typically done through evaporation of water. Evaporation intrinsically costs a lot of energy per kg of evaporated water. Also heating often degrades or even destroys the functionality of biobased materials, as proteins are denatured, and oils may be oxidised.

Instead of using heat, electricity may be directly used for water removal. Electrical driving forces can be very large, even at moderate potential gradients. An added benefit of using electricity as driving force, is that it acts within any material that conducts electricity. This means that, even when the material is already a (semi-) solid, one can still exert an effective driving force on the water inside the material.

To allow optimum direct use of electricity, we distinguish 3 different regimes:

- Dilute regime: By means of hydrogel-membrane electrodialysis water will be extracted from dilute streams.

- Semi-solid regime: The process of electro-osmosis will be developed to remove water from semi-solids.

- Solid regime: Drying towards a dried product with low water activity and extended shelf-life will be achieved via electro-hydrodynamic drying.

Anticipated results

- Three scalable electrically-driven dewatering & drying technologies

- Much lower energy consumption by avoiding or reducing evaporation.

- Better quality of product from lower temperature and no exposure to hot air.

For developing electrically-driven key technologies for food and biomass processing this research community is brought together.

The combination with a well-balances set of biomass materials, plus the capabilities of the equipment manufacturers will ensure success towards our goals of strongly reducing energy consumption, milder process conditions and more complete use of the raw materials by utilizing the water coming from the biomass. All academic and industrial partners bring complementary expertise.

Also interesting to read

Let’s get in touch

For more information please contact project leader Maarten Schutyser.

You might also be interested in

Acknowledgement & partners

This project KICH1.ST01.20.012 is part of the research programme NWO KEY Enabling Technologies which is (partly) financed by the Dutch Research Council (NWO)