Completed

HF2N – High Flux 2D Nanosheet membranes

High Flux 2D Nanosheet membranes to demonstrate and validate the high potential of a new class of inorganic high flux 2D Nanosheet membranes on a practical scale

Completed

CIRCPET – Circular PET trays for perishable food applications

PET trays are currently difficult to recycle. How can we create a fully circular PET tray solution that meets market demands while minimizing environmental impact?

Completed

COSMOS – Organic solvent nanofiltration membranes on low cost ceramic supports

The COSMOS-project found that membrane technology has the potential to replace or supplement current inefficient distillation processes.

Completed

PROVE IT

PROVE IT is all about the technical feasibility of the production of methanol from CO2 waste gas.

Completed

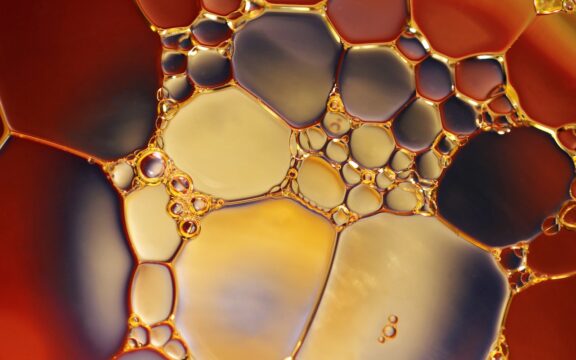

COLFILM – Collapsing Films in Emulsions

In this project computer simulations are used to reveal the impact of a crucial underlying phenomenon: little waves on the surface of droplets that can suddenly grow and thus accelerate...

Completed

FreezeCon – Freeze Concentration

Saving energy, improving product quality with freeze concentration as economically feasible bulk dewatering technology. Background Several technologies are available for liquid concentration in the food industry, the most common being...

New

HP4INDUSTRY – Enhance collaboration between industry and heat pump stakeholders

The HP4INDUSTRY project pairs ambitious climate targets with concrete, replicable process integrated solutions for industrial heating and cooling, enabling cleaner, competitive manufacturing for Europe’s future.

Completed

GRIP on Drying

This project investigates how inline sensors can help improving product quality and efficiency.

Completed

ISRO – Implementation of Solvent Recovery in edible Oil

The ISRO project delivers a proof-of-principle of organic solvent nanofiltration-based solvent recovery for two cases. The first case is an integration of OSN with the current distillation process at IOI...

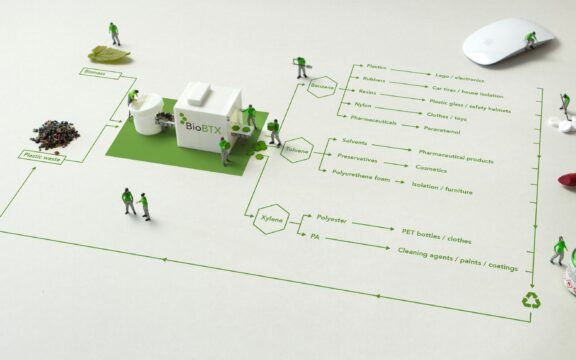

Circular Aromatics – Turning Waste into High-Value Circular Plastics

As the world moves toward net-zero carbon goals, the demand for sustainable materials is rapidly increasing. Plastics, essential in countless applications, must evolve to meet the demands of a circular,...

FLEXSTEAM – Development of heat storage for industrial steam

The FLEXSTEAM project aims to improve the way we can store and re-use thermal energy by using so called ‘Phase Changing Materials’ (PCMs). To achieve a fully circular economy we...

Flexible Efficient Electrification of Industrial Heat Cases

This project will develop innovative process designs solving the efficient flexible electrification challenge.

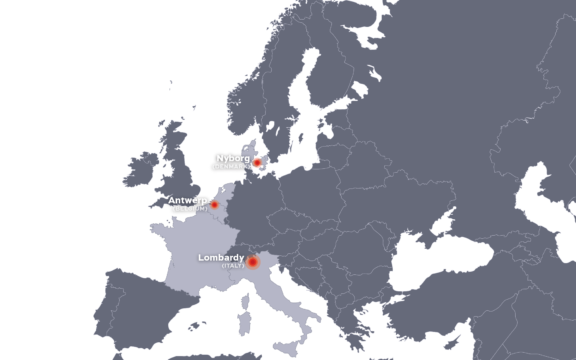

R-ACES – FRamework for Actual Cooperation on Energy on Sites and Parks

R-ACES aims to turn high-potential, high-impact industrial clusters into eco-regions with at least 10% reduction in emissions in smart energy.

Completed

COMPACT – Pulsed Compression II

The goal of this project was to produce ethylene from methane using pulsed compression technology and to determine the feasibility for industrial applications.

Completed

ADVANCED PROCESS CONTROL for dynamic operation of a large-scale test electrolyser

In this project we will researching and modelling the impact of variable operation on large-scale test electrolyser performance in green hydrogen.

CRUISE – Cost Reduction Industrial Heatpumps

CRUISE project aims to develop 50% less expensive heat pump technology that generates heat in an economically feasible way

Completed

Engender: Compact Energy Efficient Dryer

Engender works on an energy efficient drying method of foods. Expected energy savings are estimated up to 30%.

Completed

Hydrohub GigaWatt Scale Electrolyser

We are an important step further towards a Dutch hydrogen economy: the design for an advanced green hydrogen plant at large scale.

Completed

Green Hydrogen Inherent Safety Practices on Large Industrial Scale

This project will develop a uniform safety approach and increase awareness of safety for industrial scale electrolysis plants.

FlexPower: Accelerating industrial electrification for a CO2-neutral future

Industrial electrification is key to achieving the Netherlands’ goal of reducing CO2 emissions by 60% by 2030 and becoming climate-neutral by 2050. The FlexPower project focuses on flexible and efficient...

Completed

COMPRESORP

COMPRESORP focuses on upgrading low temperature waste water streams of separation processes with compression resorption heat pumps.

TEXPOWER – Textile Polycotton Waste Evaluation & Recycling

The TEXPOWER project aims to enable a transparent, circular polycotton textile value chain for a sustainable industry in the Netherlands.

Advanced Carbohydrates Biorefinery: From Waste to Value

Every year, large amounts of tertiary cellulose end up being incinerated. This results in unnecessary CO₂ emissions and loss of valuable material. The ACB project develops an alternative route: one...

PoSiMem – Periodic organosilica nanofiltration membranes

This project aims to develop robust, reproducible and easy to scale-up approaches for the production of novel nanofiltration (NF) membranes.