Completed

Probiotics – Low energy living bacterial food formulations

Research towards a novel and generic strategy for probiotics in low energy living bacterial food formulations

CRUISE – Cost Reduction Industrial Heatpumps

CRUISE project aims to develop 50% less expensive heat pump technology that generates heat in an economically feasible way

Completed

e-Missi0n MOOI

e-Missi0n developed two technological routes for the emission free production of low-carbon olefins.

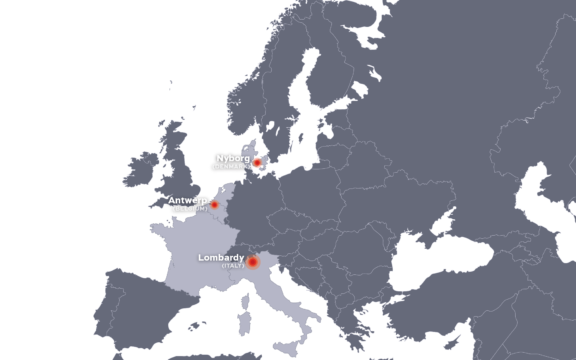

R-ACES – FRamework for Actual Cooperation on Energy on Sites and Parks

R-ACES aims to turn high-potential, high-impact industrial clusters into eco-regions with at least 10% reduction in emissions in smart energy.

Advanced Carbohydrates Biorefinery: From Waste to Value

Every year, large amounts of tertiary cellulose end up being incinerated. This results in unnecessary CO₂ emissions and loss of valuable material. The ACB project develops an alternative route: one...

New

ECONEXT – Enabling protein CONcentrates for EXTrusion

ECONEXT paves the way for a sustainable shift in protein production—one that’s not just better for the planet, but also economically viable and locally rooted.

Completed

EEMS – Energy Efficient Milky Sprays

Spray drying is a very energy intensive process. EEMS is about energy efficient drying which can lead to 20% energy reduction.

Completed

PRIDES: Deep Eutectic Solvents in the Paper Industry

The European project cluster aims to approach 80% CO2 emission reduction in the lignocellulose processing chain.

FLEXSTEAM – Development of heat storage for industrial steam

The FLEXSTEAM project aims to improve the way we can store and re-use thermal energy by using so called ‘Phase Changing Materials’ (PCMs). To achieve a fully circular economy we...

Completed

ReCYCLE – Electrical bike with durable circular plastic parts

ReCYCLE is a cutting-edge project that combines electric bikes with durable circular plastic parts, pushing the boundaries of innovation in sustainability.

Completed

Steam and condensate quality

This project focuses on requiering better insights into the distribution and behaviour of conditioning chemicals that is used in their steam-water cycles and condensate polishing. Process industries strive for more...

Completed

Scissors – Super Critical Industrial Solution for Suspended Organic Residual Streams

Scissors researches the processing of specific wet waste streams through the potential of super critical water (SCW) technology.

Completed

ZERO BRINE

The ZERO BRINE project combines technologies to recover products of high quality and sufficient purity from brine.

Completed

SUPP – Steel Slag Upgrading and PCC Production

The aim of the SUPP project is to create one combined and integrated robust batch process in order to stabilize and upgrade steel slag and neutralize hydrochloric acid. In addition, it...

ReValue – Recovery of Valuable minerals with hybrid ceramic membrane crystallization

The ReValue project explores the potential of membrane crystallization, a promising technology to recover valuable compounds from aqueous streams.

Completed

Plasma Conversions

Industrial ammonia production is energy intensive and has a huge footprint. A plasma integrated water electrolyser provides an ecologically clean alternative process to Haber-Bosch.

Completed

Cell-U-Value

Cell-U-Value developed and utilized the capabilities of tertiary cellulose as a feedstock for biobased and sustainable chemicals to its fullest potential.

Completed

Thin Film Drying

A part of the drying and dewattering program with Thin Film Drying as a new technology for product quality and energy consumption

AutoPlastic: Shaping the Future of Automotive and Plastic Recycling

As the automotive industry faces new recycling legislation, the AutoPlastic project leads the way in boosting car plastic recycling. It helps the Dutch automotive sector stay ahead by developing solutions...

GAMBA – Green Alloys Modelling Better Approaches

The GAMBA project seeks to reduce the carbon footprint of the iron and steel industry by transitioning from natural gas to hydrogen-based direct reduction (DRI) processes.

Completed

Biorefinery Program

Biorefinery enables the production of healthy ingredients and the recovery of valuable components (i.e. proteins) out of process streams.

Completed

PTTP – Process Technology Talent Program

PTTP was a talent program for promising HBO students who aim to drive sustainability in the process technology.

New

SEUSS – Saving Energy by Upcycling of Side Streams

The shift to plant‑based proteins demands smarter, cleaner processing. SEUSS develops new ways to reduce energy use and recover valuable resources from side streams. In Short Energy-related challenges The protein...

Recircanol: Circular recovery of ethanol from alkaline-ethanol media at high pH using membrane technology

This project develops nanofiltration membranes and membrane modules for alkaline-alcohol media at high pH for the purification of ethanol and caustic.