This project aims to improve the circularity of polyolefin-based packaging materials by overcoming technological barriers. The project has yielded important results that will help us move from a linear to a circular system.

In short:

- The relationship between the various players in the plastic packaging value chain is complex

- The choices made by one link can greatly impact the quality and quantity of plastic material

- Understanding these relationships will help us design the value chain to meet national and European circularity and climate targets

This project has led to a better understanding of the role each partner can play in moving from a linear value chain towards a circular value chain, as a result of good interaction and exchange of information among the consortium partners.

Ronald Korstanje, Director of the Circular Plastics Initiative

What has been done?

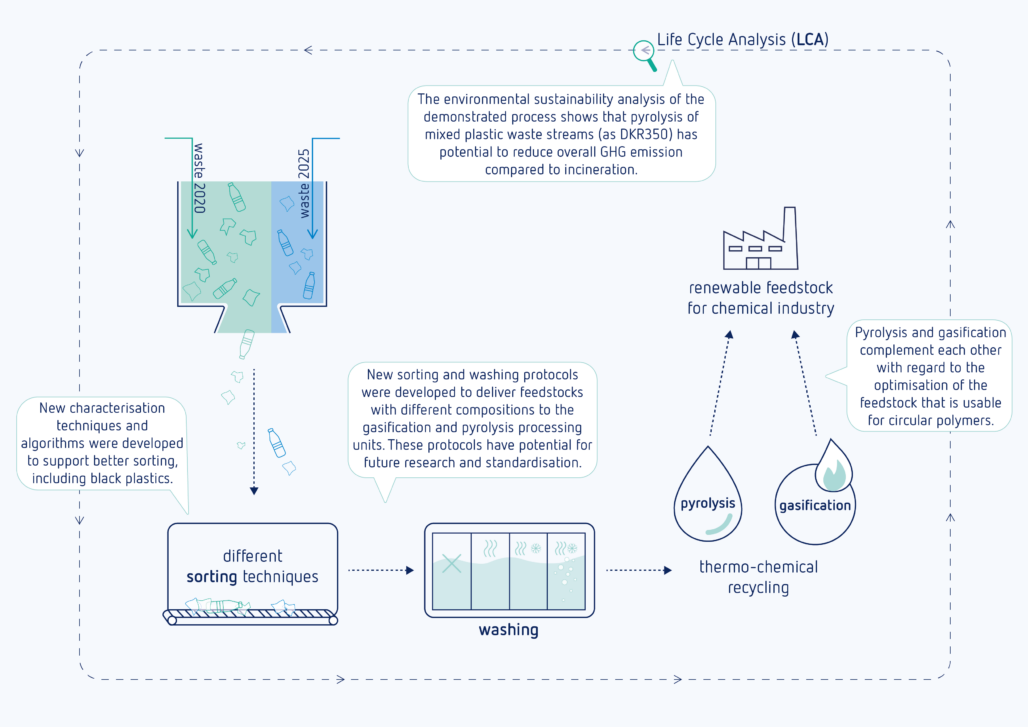

The goal of this project was to gain a better understanding of the feedstock – process – output relationship of polyolefin-rich feedstocks using pyrolysis and gasification as processing techniques. The feedstock was derived from consumer-based packaging waste (PMD). Through the use of various sorting and washing protocols, we were able to deliver feedstocks with different compositions.

Additionally, sorting tests were set up to understand the impact of newly designed products on the composition of the feedstock and processing. We also developed and evaluated new characterization techniques for sorting black plastics and created new algorithms to support better sorting. Pyrolysis and gasification trials were conducted at both lab and pilot scales, testing with different types of feedstocks and process settings. Finally, an environmental sustainability analysis of the entire chain was conducted.

The scientific output

On design for recycling and sortability

Sortability of packaging towards dummy plastic streams for chemical recycling

This study has determined the sortability of 16 different newly designed packaging materials to create 2 benchmark dummy streams, representing the composition of current and future household plastic packaging waste. Results show that in general, all packaging ends up in the 2D stream, and multilayer materials containing aluminium or PVC are difficult to sort.

Non-Negative Matrix Factorization and Systematic Simplification of Hyperspectral Images for High-Speed Plastic Sorting

The study proposes a two-step procedure using Non-Negative Matrix Factorization (NMF) and Convex-hull for simplifying and speeding up the analysis of large hyperspectral imaging (HSI) datasets for plastic sorting. It demonstrates that this method can increase the accuracy and efficiency of plastic sorting for the circular economy. This is achieved by removing uninformative and redundant pixels and wavelengths from HSI data and selecting essential pixels/wavelengths from foreground objects

Mono/Multilayered Plastic Sorting Based on Multi-Block Non-Negative Matrix Factorization

A new method called Multi-Block Non-Negative Matrix Factorization (MB-NMF) was developed for sorting mono/multilayered plastics which was found to have higher accuracy rate compared to existing methods.

On pyrolysis

Pyrolysis of Dutch mixed plastic waste: Lifecycle GHG emissions and carbon recovery efficiency assessment

The study evaluates the lifecycle greenhouse gas (GHG) emissions of pyrolyzing Dutch mixed plastic waste. It finds that while pyrolysis reduces the reliance on virgin fossil feedstocks, the overall GHG savings depend on process efficiency and the end use of the pyrolysis oil. The research highlights that emissions can be minimized if the oil replaces virgin naphtha in chemical production rather than being used as a fuel. However, contamination and energy demands remain key challenges for optimizing the environmental benefits of pyrolysis.

Pyrolysis of mixed plastic waste (DKR-350): Effect of washing pre-treatment and fate of chlorine

This study investigates the results of pyrolysis of a post-consumer plastic waste stream (DKR-350) at laboratory scale. The research showed that washing the DKR 350 feedstock effectively lowers the biogenic, inorganic, and halogen content, but does not affect the yield of the desired oil/wax product (66-69 wt.%). The oxygen content of the oil/wax is also reduced during pyrolysis. However, the chlorine content in the oil/wax is still high, indicating the presence of recalcitrant organochlorines. This means that post-treatment still is required to upgrade the product before use in any application.

Pyrolysis of mixed plastic waste: Predicting the product yields

This study explores the predictability of pyrolysis results for mixed plastics. The study found that a linear model could accurately predict the oil/wax yield of mixed plastic streams, with a maximum deviation of 8%. However, the presence of significant amounts of a specific type of plastic, i.e. PET, negatively affects the production of the condensable product and promotes the formation of solid products beyond the expected predicted values. It is also found that the model could predict the aliphatic carbon yield in the condensable product from plastic waste streams with high accuracy. The study’s findings have important implications for the recycling and disposal of mixed plastic waste and the development of more efficient pyrolysis processes.

Join the Circular Plastics Initiative

This project has yielded numerous innovative results in the processing of plastic waste through various methods, such as gasification and pyrolysis. But our work is not done yet. We continue to strive for even greater understanding of the circularity of plastics.

Together, we can make a meaningful impact on reducing plastic waste and preserving our planet for future generations. Don’t miss the opportunity to be a part of this revolutionary movement. You can find our contact information below, or join our LinkedIn community.

This is a project of the Circular Plastics Initiative, powered by ISPT and DPI.

You might also be interested in

Acknowledgement & partners

This project is co-funded with subsidy from the Topsector Energy by the Ministry of Economic Affairs and Climate Policy.