Completed

Ammonia Pipeline Safety

The Clean Ammonia Platform is doing a study on safety design and risk impact of ammonia pipelines to explore ways to safely transport large volumes of ammonia by pipeline in...

New

SEUSS – Saving Energy by Upcycling of Side Streams

The shift to plant‑based proteins demands smarter, cleaner processing. SEUSS develops new ways to reduce energy use and recover valuable resources from side streams. In Short Energy-related challenges The protein...

Completed

CirBind – Circular binder applications

ISPT's Cirbind project scales up the Plantics-GX bioresin production process to generate safe, strong & high impact circular binder applications.

Completed

Cell-U-Value

Cell-U-Value developed and utilized the capabilities of tertiary cellulose as a feedstock for biobased and sustainable chemicals to its fullest potential.

Completed

StAgglop: Reducing energy use and material loss by better control of agglomeration during spray drying

Project stAgglop aims to improve agglomeration control to contribute to the reduction of emissions for industrial drying systems.

Completed

Fine Biofuels

In the Netherlands there is a total quantity of 1 million tons of roadside grass which must be mowed at least twice a year to keep the roadside banks safe....

Completed

Plasma Conversions

Industrial ammonia production is energy intensive and has a huge footprint. A plasma integrated water electrolyser provides an ecologically clean alternative process to Haber-Bosch.

Completed

FreezeCon – Freeze Concentration

Saving energy, improving product quality with freeze concentration as economically feasible bulk dewatering technology. Background Several technologies are available for liquid concentration in the food industry, the most common being...

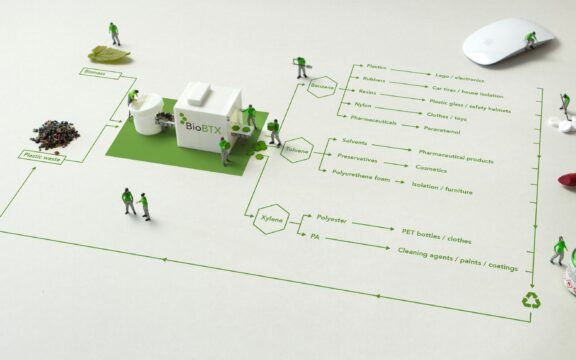

Circular Aromatics – Turning Waste into High-Value Circular Plastics

As the world moves toward net-zero carbon goals, the demand for sustainable materials is rapidly increasing. Plastics, essential in countless applications, must evolve to meet the demands of a circular,...

Renewable Building Blocks from Complex and wet waste Streams (ReBBloCS)

The ReBBloCS project aims to develop new circular value chains for the valorisation of complex and mixed waste streams into valuable chemical products.

Completed

Green Hydrogen Inherent Safety Practices on Large Industrial Scale

This project will develop a uniform safety approach and increase awareness of safety for industrial scale electrolysis plants.

Completed

e-Missi0n MOOI

e-Missi0n developed two technological routes for the emission free production of low-carbon olefins.

New

Ammonia to Power

The Ammonia to Power project explores the techno-economic potential of ammonia powered electricity generation.

CRUISE – Cost Reduction Industrial Heatpumps

CRUISE project aims to develop 50% less expensive heat pump technology that generates heat in an economically feasible way

Completed

ERGO – Energy Reduction by Condition-based Monitoring

Unlocking energy efficiency and fault detection with electrical signal analysis Electric motors and rotating equipment—such as pumps, fans, compressors, and conveyors—consume over 40% of global electricity. However, nearly one-third of...

Completed

Biorefinery Program

Biorefinery enables the production of healthy ingredients and the recovery of valuable components (i.e. proteins) out of process streams.

Completed

Towards improved circularity of polyolefin-based packaging

This project aims at improved circularity of polyolefin-based packaging materials through overcoming technological hurdles.

Completed

Next Level Solid Oxide Electrolysis

Solid Oxide Electrolysis is a technology with great potential for large-scale green hydrogen production by water electrolysis. This project explores the upscaling potential of SOEC.

Completed

IMPACCT – Improved process performance by process intensification in centrifugal contactors

Centrifugal contactors, such as RPBs, could provide significant improvement of separation processes in the chemical industry. This technology seems potentially suitable for replacing or debottlenecking current unit operations which suffer...

DRAGONS Egg – Increasing energy efficiency by steering DRoplet AGglomeratiON in Spray dryers

The DRAGONS Egg-project aims to unravel the dynamics of atomisation behaviour in drying and agglomeration of the droplet.

SUNSOLr: Electrification of Chemical Conversions

The SUNSOLr project is dedicated to developing technologies for the direct electrification of chemical conversions, focusing on CO2 and H2O/H2 to produce chemicals like CO, CH4, olefins, and methanol.

Completed

SiC – Silicon Carbide membranes for innovative oil-in-water separations

This project investigates the behavior of silicon carbide membranes in pilot trials. These determine fouling, cleaning options, cleaning frequency and the consequences for the long term performance and economics. Test...

Completed

HyScaling – Making better electrolyzers in a better way

HyScaling aims to scale electrolysis capacity up to 5GW by 2030 so the Netherlands can play a key role in the global green hydrogen economy.

Completed

PTTP – Process Technology Talent Program

PTTP was a talent program for promising HBO students who aim to drive sustainability in the process technology.