Completed

EAMS – Energy efficient Affinity-driven Molecular Separation

The aim of the EAMS project is to: Application New or improved affinity separation options for selected cases: extractive distillation and (reactive) liquid-liquid extraction.

Completed

Green Hydrogen Inherent Safety Practices on Large Industrial Scale

This project will develop a uniform safety approach and increase awareness of safety for industrial scale electrolysis plants.

TREPS – Trace Removal Using Electrically Powered Separations

In a circular economy, traces need to be removed to keep the loop clean. TREPS deals with trace removal using electricity.

Completed

GreenWedge

The GreenWedge project helps SMEs actively market their sustainable technology.

Completed

H2-Safety2 – Safety Standardisation of Green Hydrogen Electrolyser Systems

This hydrogen safety project aimed to develop recommendations for standardisation, meeting process safety requirements for large scale water electrolysis. This is an important step to enable a safe, integrated hydrogen-based...

Completed

Thin Film Drying

A part of the drying and dewattering program with Thin Film Drying as a new technology for product quality and energy consumption

Bio4Steel

How can biochar — an organic material created by heating wood or other plant material in the absence of oxygen — play a role in replacing fossil coal in the...

Completed

Scissors – Super Critical Industrial Solution for Suspended Organic Residual Streams

Scissors researches the processing of specific wet waste streams through the potential of super critical water (SCW) technology.

GAMBA – Green Alloys Modelling Better Approaches

The GAMBA project seeks to reduce the carbon footprint of the iron and steel industry by transitioning from natural gas to hydrogen-based direct reduction (DRI) processes.

Completed

ZERO BRINE

The ZERO BRINE project combines technologies to recover products of high quality and sufficient purity from brine.

Renewable Building Blocks from Complex and wet waste Streams (ReBBloCS)

The ReBBloCS project aims to develop new circular value chains for the valorisation of complex and mixed waste streams into valuable chemical products.

Completed

S2C – Steel2Chemicals

The project Steel2Chemicals develops a closed value chain in which CO from steel production is used as feedstock for the chemical industry.

ReCoVR – Recovery and Circularity of Valuable Resources

ReCoVR designs and develops novel functional materials and technologies to selectively recover high-value molecules.

Completed

Plasma Conversions

Industrial ammonia production is energy intensive and has a huge footprint. A plasma integrated water electrolyser provides an ecologically clean alternative process to Haber-Bosch.

ENCORE – nExt geNeration COmpRession hEat pump

This project demonstrates the enhancement of compression heat pump performance by using a pilot scale test unit.

Completed

WeCare – We Create Awareness & Reduce Energy

The WeCARE project demonstrated the possibilities of Artificial Intelligence technology of EnergQ at a selected number of end users. EnerGQ’s self-learning energy management technology unveiled the excessive energy consumption and with that...

Completed

Next Level Solid Oxide Electrolysis

Solid Oxide Electrolysis is a technology with great potential for large-scale green hydrogen production by water electrolysis. This project explores the upscaling potential of SOEC.

Completed

RiConfigure

RiConfigure is about involving a diverse group of actors in society’s innovation team.

Completed

ADVANCED PROCESS CONTROL for dynamic operation of a large-scale test electrolyser

In this project we will researching and modelling the impact of variable operation on large-scale test electrolyser performance in green hydrogen.

FLEXSTEAM – Development of heat storage for industrial steam

The FLEXSTEAM project aims to improve the way we can store and re-use thermal energy by using so called ‘Phase Changing Materials’ (PCMs). To achieve a fully circular economy we...

Completed

C2V – Carbon2Value

Innovative CO2 separation technology aims to reduce emissions in steel industry. This project revolves around an innovative technology with the potential to reduce CO2 emissions across the major energy intensive...

Completed

RMZD – Radial Multi-Zone Drying

The Radial Multi-zone Dryer (RMD) project investigates new type of spray dryer for premium product properties and low specific energy consumption.

COMTA – COMpact modular Thermo Acoustic heat pump

To further develop the compact electrically driven thermoacoustic heat (TA) pump technology and to prepare for technical demonstration on full scale. The industry is a large consumer of energy and...

Completed

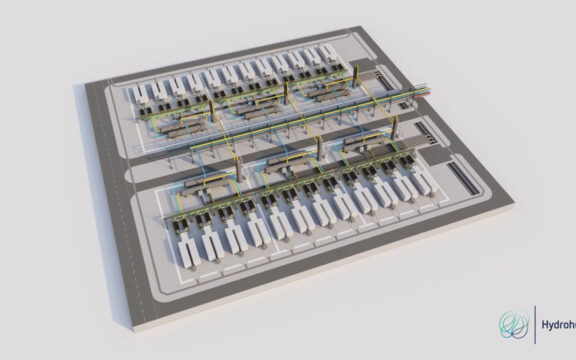

HyScaling – Making better electrolyzers in a better way

HyScaling aims to scale electrolysis capacity up to 5GW by 2030 so the Netherlands can play a key role in the global green hydrogen economy.