SUNSOLr: Electrification of Chemical Conversions

The SUNSOLr project is dedicated to developing technologies for the direct electrification of chemical conversions, focusing on CO2 and H2O/H2 to produce chemicals like CO, CH4, olefins, and methanol.

Completed

IMPACCT – Improved process performance by process intensification in centrifugal contactors

Centrifugal contactors, such as RPBs, could provide significant improvement of separation processes in the chemical industry. This technology seems potentially suitable for replacing or debottlenecking current unit operations which suffer...

Cascade Recyling of Plastic Film (CaRP)

The CaRP project will find and show realistic cascade recycling routes for packaging film waste to minimise the amount of plastic film waste that is incinerated and to maximise the...

Completed

INSPEC – Integrating sensor based process monitoring and advanced process control

INSPEC quantitatively integrates information from state-of-the-art Process Analytical Technology, process measurements and dynamic process models (data driven or physics-based) into Advanced Process Control. This will induce a step-change with respect to...

Completed

SiC – Silicon Carbide membranes for innovative oil-in-water separations

This project investigates the behavior of silicon carbide membranes in pilot trials. These determine fouling, cleaning options, cleaning frequency and the consequences for the long term performance and economics. Test...

STARBATCH- Sodium Tetra chloro Aluminate Recyclable BATtery CHemicals

Storage of electricity will play a major role in the energy transition. Lithium-based batteries are now being produced on a large scale, but require expensive resources that are not widely...

Completed

HOPy – Headstart on pyrolysis

HOPy wants to find a solution that mitigates the environmental impact of plastic waste and taps into its potential as a resource for creating new materials.

Completed

ECWRTI – Electrocoagulation for Water Recycling in Textile Industry

The ECWRTI project is about closing the waterloop in the textile industry.

Completed

HyScaling – Making better electrolyzers in a better way

HyScaling aims to scale electrolysis capacity up to 5GW by 2030 so the Netherlands can play a key role in the global green hydrogen economy.

Completed

StAgglop: Reducing energy use and material loss by better control of agglomeration during spray drying

Project stAgglop aims to improve agglomeration control to contribute to the reduction of emissions for industrial drying systems.

New

RePlaCE – Recycling of Plastics from Cars and Electronic Equipment

In this project we accelerate recycling of high‑quality engineering plastics from cars and electronic equipment.

Completed

Methanol, the LOGIC Choice!

The LOGIC project scales-up the Liquid-Out Gas-In Concept reactor for methanol synthesis from CO2 and sustainable hydrogen.

Completed

IMPROVISE – Improved process operation via rigorous simulation models

Improved daily operations of important chemical processes in the Dutch chemical industry through operation technology based on detailed physical models. Incentive Being able to anticipate what a chemical process is...

Completed

COSMOS – Organic solvent nanofiltration membranes on low cost ceramic supports

The COSMOS-project found that membrane technology has the potential to replace or supplement current inefficient distillation processes.

Completed

VERA – Accelerating Energy Transition Realization Approach

The Vera project aims to further develop and implement industrial heat pumps in the Netherlands.

Completed

COMPRESORP

COMPRESORP focuses on upgrading low temperature waste water streams of separation processes with compression resorption heat pumps.

Completed

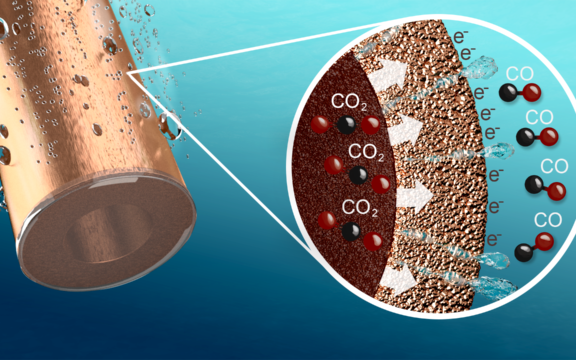

E3C – Electrons to Close the Carbon Cycle

Development and evaluation of tubular and flat porous electrodes for the electrochemical conversion of gasses at ambient temperature. Motivation Renewable electricity (RE) generation is currently growing at a rapid pace....

Bio4Steel

How can biochar — an organic material created by heating wood or other plant material in the absence of oxygen — play a role in replacing fossil coal in the...

Completed

AIDA – Accelerate the Integration of Digitalisation Acceptation

The AIDA project performs research towards predictive capabilities and integration of digital technologies at the various levels of individual processes.

Completed

LEMPLAR – Losses & Emissions in Plastic Recycling

The plastic recycling process today has losses and emissions, such as microplastics, inks and incorrectly sorted plastics. This prevents us of closing the plastic cycle.

Completed

Green Hydrogen Inherent Safety Practices on Large Industrial Scale

This project will develop a uniform safety approach and increase awareness of safety for industrial scale electrolysis plants.

FlexPower: Accelerating industrial electrification for a CO2-neutral future

Industrial electrification is key to achieving the Netherlands’ goal of reducing CO2 emissions by 60% by 2030 and becoming climate-neutral by 2050. The FlexPower project focuses on flexible and efficient...

Completed

Towards improved circularity of polyolefin-based packaging

This project aims at improved circularity of polyolefin-based packaging materials through overcoming technological hurdles.

Completed

S2C – Steel2Chemicals

The project Steel2Chemicals develops a closed value chain in which CO from steel production is used as feedstock for the chemical industry.