STARBATCH- Sodium Tetra chloro Aluminate Recyclable BATtery CHemicals

Storage of electricity will play a major role in the energy transition. Lithium-based batteries are now being produced on a large scale, but require expensive resources that are not widely...

Completed

HyChain – Energy Carriers and Hydrogen Supply Chain

The HyChain project is focused on a strategic understanding of the drivers behind global emergence of future renewable hydrogen value chains.

Completed

SAAI – Social Acceptance of AI in Industry

The SAAI project focuses on accelerating the implementation of Artificial Intelligence (AI) in industry, leading to an energy use reduction of 5-40%, an increased competitiveness of industry, and increased economic...

Completed

Methanol, the LOGIC Choice!

The LOGIC project scales-up the Liquid-Out Gas-In Concept reactor for methanol synthesis from CO2 and sustainable hydrogen.

Completed

COMPACT – Pulsed Compression II

The goal of this project was to produce ethylene from methane using pulsed compression technology and to determine the feasibility for industrial applications.

Completed

DC-DC converters – Green GW Hydrogen Plant

In this project we investigate DC-DC connections for large-scale green hydrogen plants to address space constraints, reduce investment costs (up to 25%), and mitigate significant electricity losses compared to traditional...

Completed

ReCYCLE – Electrical bike with durable circular plastic parts

ReCYCLE is a cutting-edge project that combines electric bikes with durable circular plastic parts, pushing the boundaries of innovation in sustainability.

COMTA – COMpact modular Thermo Acoustic heat pump

To further develop the compact electrically driven thermoacoustic heat (TA) pump technology and to prepare for technical demonstration on full scale. The industry is a large consumer of energy and...

Flexible Efficient Electrification of Industrial Heat Cases

This project will develop innovative process designs solving the efficient flexible electrification challenge.

Completed

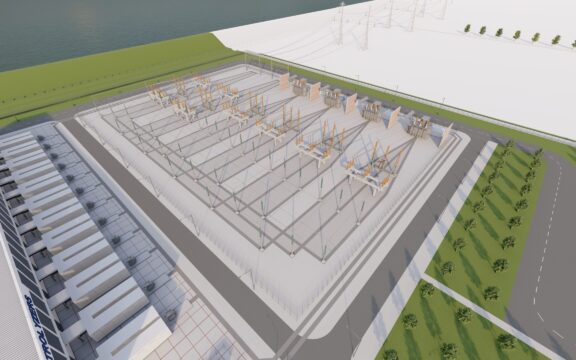

Hydrohub GigaWatt Scale Electrolyser

We are an important step further towards a Dutch hydrogen economy: the design for an advanced green hydrogen plant at large scale.

ReCoVR – Recovery and Circularity of Valuable Resources

ReCoVR designs and develops novel functional materials and technologies to selectively recover high-value molecules.

Completed

EAMS – Energy efficient Affinity-driven Molecular Separation

The aim of the EAMS project is to: Application New or improved affinity separation options for selected cases: extractive distillation and (reactive) liquid-liquid extraction.

TEXPOWER – Textile Polycotton Waste Evaluation & Recycling

The TEXPOWER project aims to enable a transparent, circular polycotton textile value chain for a sustainable industry in the Netherlands.

Completed

GRIP on Drying

This project investigates how inline sensors can help improving product quality and efficiency.

CRUISE – Cost Reduction Industrial Heatpumps

CRUISE project aims to develop 50% less expensive heat pump technology that generates heat in an economically feasible way

DRAGONS Egg – Increasing energy efficiency by steering DRoplet AGglomeratiON in Spray dryers

The DRAGONS Egg-project aims to unravel the dynamics of atomisation behaviour in drying and agglomeration of the droplet.

Completed

FreezeCon – Freeze Concentration

Saving energy, improving product quality with freeze concentration as economically feasible bulk dewatering technology. Background Several technologies are available for liquid concentration in the food industry, the most common being...

Completed

PROVE IT

PROVE IT is all about the technical feasibility of the production of methanol from CO2 waste gas.

Completed

Single Droplet Modelling

Multicomponent analysis of single droplet spray drying techniques and PhD research for the drying and dewatering program of ISPT.

SUNSOLr: Electrification of Chemical Conversions

The SUNSOLr project is dedicated to developing technologies for the direct electrification of chemical conversions, focusing on CO2 and H2O/H2 to produce chemicals like CO, CH4, olefins, and methanol.

Completed

Thin Film Drying

A part of the drying and dewattering program with Thin Film Drying as a new technology for product quality and energy consumption

Completed

Scissors – Super Critical Industrial Solution for Suspended Organic Residual Streams

Scissors researches the processing of specific wet waste streams through the potential of super critical water (SCW) technology.

Completed

SUPP – Steel Slag Upgrading and PCC Production

The aim of the SUPP project is to create one combined and integrated robust batch process in order to stabilize and upgrade steel slag and neutralize hydrochloric acid. In addition, it...

FOMM – Forward Osmosis Membrane and Module development

Forward osmosis (FO) is a technology recently developed on academic level, with very few example applications in the market, despite its strong benefits. FO is an energy efficient and effective...