Completed

GRIP on Drying

This project investigates how inline sensors can help improving product quality and efficiency.

Completed

Green Hydrogen Inherent Safety Practices on Large Industrial Scale

This project will develop a uniform safety approach and increase awareness of safety for industrial scale electrolysis plants.

Completed

BRECSIT – Bio-based REsin CompoSIte Technologies

Plantics-GX composites can replace conventional, fossil-based plastic composites.

Completed

ZERO BRINE

The ZERO BRINE project combines technologies to recover products of high quality and sufficient purity from brine.

EPRoTrans – Energy reduction technologies enabling PRotein Transition

Project Energy Efficient Protein Transition (EProTrans) investigates the processing of several mixed plant-based streams to produce plant-based proteins.

The Heat Is On

The Heat is On aims to make processes for dewatering, drying and heat integration more efficient.

Completed

ADVANCED PROCESS CONTROL for dynamic operation of a large-scale test electrolyser

In this project we will researching and modelling the impact of variable operation on large-scale test electrolyser performance in green hydrogen.

Completed

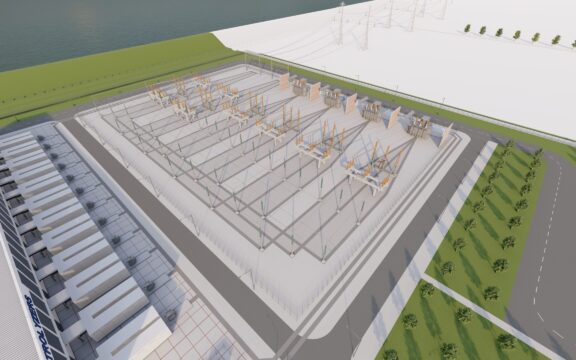

DC-DC converters – Green GW Hydrogen Plant

In this project we investigate DC-DC connections for large-scale green hydrogen plants to address space constraints, reduce investment costs (up to 25%), and mitigate significant electricity losses compared to traditional...

Fingerprint 2 Footprint

Fingerprint 2 Footprint translates chemical fingerprint measurements inside and near chemical processes to reduce environmental footprints, while retaining or improving process economy and consistency.

Completed

VERA – Accelerating Energy Transition Realization Approach

The Vera project aims to further develop and implement industrial heat pumps in the Netherlands.

Completed

STNF – Solvent Tolerant Nanofiltration and reverse osmosis membranes for the purification of industrial aqueous streams

Many industrial process streams contain water with solvents and other organic components. Such streams need to be purified from these components or need to be treated before further handling. Polymeric...

STARBATCH- Sodium Tetra chloro Aluminate Recyclable BATtery CHemicals

Storage of electricity will play a major role in the energy transition. Lithium-based batteries are now being produced on a large scale, but require expensive resources that are not widely...

GAMBA – Green Alloys Modelling Better Approaches

The GAMBA project seeks to reduce the carbon footprint of the iron and steel industry by transitioning from natural gas to hydrogen-based direct reduction (DRI) processes.

Completed

DISCO – Downstream ISolation of high-value COmponents

The Downstream ISolation of high-value Components (DISCO) aims to lower the material use and increase the energy-efficiency.

Completed

RFS2 – Radio Frequent Sterilization 2

The project Radio Frequent Sterizilation 2 (RFS2) is focused on the development of RF in-pack sterilization of foods. The project is a continuation of the JIP-project Radio Frequent Sterilization (RFS)...

Completed

CirBind – Circular binder applications

ISPT's Cirbind project scales up the Plantics-GX bioresin production process to generate safe, strong & high impact circular binder applications.

Bio4Steel

How can biochar — an organic material created by heating wood or other plant material in the absence of oxygen — play a role in replacing fossil coal in the...

Completed

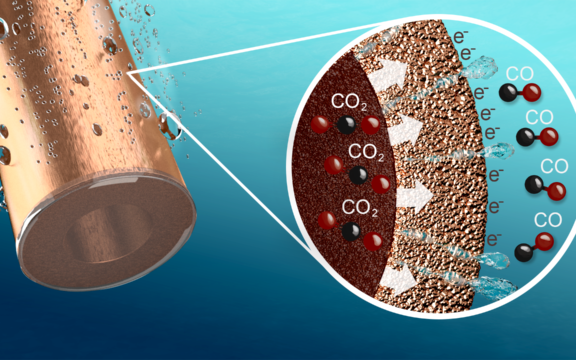

E3C – Electrons to Close the Carbon Cycle

Development and evaluation of tubular and flat porous electrodes for the electrochemical conversion of gasses at ambient temperature. Motivation Renewable electricity (RE) generation is currently growing at a rapid pace....

Completed

ERGO – Energy Reduction by Condition-based Monitoring

Unlocking energy efficiency and fault detection with electrical signal analysis Electric motors and rotating equipment—such as pumps, fans, compressors, and conveyors—consume over 40% of global electricity. However, nearly one-third of...

Completed

COMPACT – Pulsed Compression II

The goal of this project was to produce ethylene from methane using pulsed compression technology and to determine the feasibility for industrial applications.

Completed

Next Level Solid Oxide Electrolysis

Solid Oxide Electrolysis is a technology with great potential for large-scale green hydrogen production by water electrolysis. This project explores the upscaling potential of SOEC.

Completed

HyScaling – Making better electrolyzers in a better way

HyScaling aims to scale electrolysis capacity up to 5GW by 2030 so the Netherlands can play a key role in the global green hydrogen economy.

Completed

RMZD – Radial Multi-Zone Drying

The Radial Multi-zone Dryer (RMD) project investigates new type of spray dryer for premium product properties and low specific energy consumption.

Completed

HOPy – Headstart on pyrolysis

HOPy wants to find a solution that mitigates the environmental impact of plastic waste and taps into its potential as a resource for creating new materials.