Completed

Measurements 4 Management

Measurement 4 Management (M4M) focused on applying data-driven decision-making in the process industry, by combining artificial intelligence (AI) with the domain knowledge of process engineers.

Completed

Novel Process Routes – Reduction of energy use by novel process routes for food (ProFo)

Several partners are working towards a 50% reduction of energy use developing novel process routes in food processing.

Bio4Steel

How can biochar — an organic material created by heating wood or other plant material in the absence of oxygen — play a role in replacing fossil coal in the...

Completed

WeCare – We Create Awareness & Reduce Energy

The WeCARE project demonstrated the possibilities of Artificial Intelligence technology of EnergQ at a selected number of end users. EnerGQ’s self-learning energy management technology unveiled the excessive energy consumption and with that...

Cascade Recyling of Plastic Film (CaRP)

The CaRP project will find and show realistic cascade recycling routes for packaging film waste to minimise the amount of plastic film waste that is incinerated and to maximise the...

Completed

IMPACCT – Improved process performance by process intensification in centrifugal contactors

Centrifugal contactors, such as RPBs, could provide significant improvement of separation processes in the chemical industry. This technology seems potentially suitable for replacing or debottlenecking current unit operations which suffer...

SPOT: Sustainable PrOcess heaTing

SPOT (Sustainable PrOcess) aims to reduce the use of fossil energy use for industrial heat with at least 100 PJ/year in 2030.

Completed

C2V – Carbon2Value

Innovative CO2 separation technology aims to reduce emissions in steel industry. This project revolves around an innovative technology with the potential to reduce CO2 emissions across the major energy intensive...

ENCORE – nExt geNeration COmpRession hEat pump

This project demonstrates the enhancement of compression heat pump performance by using a pilot scale test unit.

COMTA – COMpact modular Thermo Acoustic heat pump

To further develop the compact electrically driven thermoacoustic heat (TA) pump technology and to prepare for technical demonstration on full scale. The industry is a large consumer of energy and...

Recircanol: Circular recovery of ethanol from alkaline-ethanol media at high pH using membrane technology

This project develops nanofiltration membranes and membrane modules for alkaline-alcohol media at high pH for the purification of ethanol and caustic.

Completed

EAMS – Energy efficient Affinity-driven Molecular Separation

The aim of the EAMS project is to: Application New or improved affinity separation options for selected cases: extractive distillation and (reactive) liquid-liquid extraction.

Completed

PRIDES: Deep Eutectic Solvents in the Paper Industry

The European project cluster aims to approach 80% CO2 emission reduction in the lignocellulose processing chain.

Completed

Plasma Conversions

Industrial ammonia production is energy intensive and has a huge footprint. A plasma integrated water electrolyser provides an ecologically clean alternative process to Haber-Bosch.

Completed

ADVANCED PROCESS CONTROL for dynamic operation of a large-scale test electrolyser

In this project we will researching and modelling the impact of variable operation on large-scale test electrolyser performance in green hydrogen.

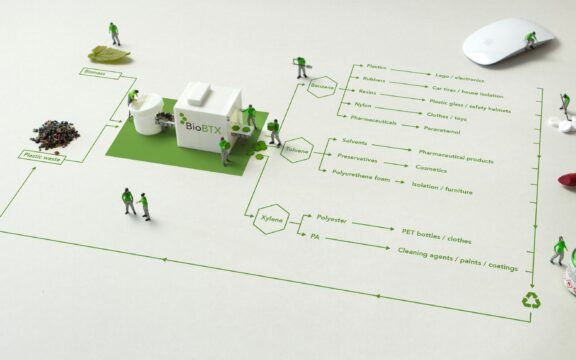

Circular Aromatics – Turning Waste into High-Value Circular Plastics

As the world moves toward net-zero carbon goals, the demand for sustainable materials is rapidly increasing. Plastics, essential in countless applications, must evolve to meet the demands of a circular,...

Completed

IMPROVISE – Improved process operation via rigorous simulation models

Improved daily operations of important chemical processes in the Dutch chemical industry through operation technology based on detailed physical models. Incentive Being able to anticipate what a chemical process is...

EPRoTrans – Energy reduction technologies enabling PRotein Transition

Project Energy Efficient Protein Transition (EProTrans) investigates the processing of several mixed plant-based streams to produce plant-based proteins.

Electrified – Electrically driven non-thermal dewatering of biomass

The aim of the Electrified project is to establish new technologies for future key technologies for biomass dewatering.

Completed

Sussic – Sustainable treatment of industrial streams

In the Sussic project, atomic layer deposition (ALD) will be used for the development of SiC NF membranes, allowing treatment of challenging industrial streams.

Completed

RFS2 – Radio Frequent Sterilization 2

The project Radio Frequent Sterizilation 2 (RFS2) is focused on the development of RF in-pack sterilization of foods. The project is a continuation of the JIP-project Radio Frequent Sterilization (RFS)...

Completed

InReP – An Integrated approach towards Recycling of Plastics

Recycling plastics is one of the biggest challenges the industry is facing today. This projects aims to overcome current challenges.

EBI – Engineering Business Intelligence

The EBI project uses data collection, data analytics and data visualization to reduce energy usage in existing processes by 5-25%.

Completed

AIDA – Accelerate the Integration of Digitalisation Acceptation

The AIDA project performs research towards predictive capabilities and integration of digital technologies at the various levels of individual processes.