In Europe alone, each year over 200 million tons of raw food supply are lost in food processing. To increase the yield of food processes, it is important to reduce and/or valorise waste and side streams. This usually requires large amounts of energy and resources. In the project Recircanol an alternative is researched.

In short:

- Large quantities of food are listed in the production process

- Recovering valuable resources from the side streams is expensive and resource intensive

- Membrane technology at high pH could make the recovery more circular and energy efficient

Recovery of solvents

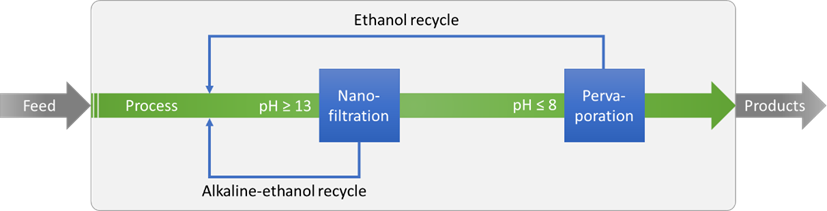

Processes that involve the use of alcohols as (anti)solvents and the application of pH switches to recover and purify (functional) ingredients of food side streams have been developed. The recovery of (anti)solvents using e.g. distillation requires significant amounts of energy, though. Membrane technology could be an alternative separation technology to make the food, biotech, and chemical industry more circular, flexible and energy-efficient.

An example of such a process is shown in the figure below:

Goal of the project Recircanol

- Develop and scientifically evaluate on lab-scale novel as well as potentially suitable commercially available nanofiltration membranes and membrane modules that can be used in alkaline-alcohol media at high pH for the purification and recovery of ethanol and caustic;

- First assessment of the techno-economic feasibility of using the developed pH-stable nanofiltration membranes in the food and chemical industry in applications characterized by extreme pH;

- Determine the feasibility of using membrane pervaporation for the recovery and purification of ethanol from water-ethanol media containing peptides, amino acids and salts.

Collaborative effort

In this consortium, Greencovery, Pervatech, SolSep, Nobian, and the University of Twente will closely collaborate to perform the various activities in this project, which includes a PhD as well as an EngD track.

Together, they aim to generate new scientific and technological knowledge on pH-stable and solvent-resistant nanofiltration membranes for use at alkaline conditions, and on pervaporation membranes for the purification of valuable components and/or the recovery of (anti)solvents.

You might also be interested in

Acknowledgement & partners