Completed

SAAI – Social Acceptance of AI in Industry

The SAAI project focuses on accelerating the implementation of Artificial Intelligence (AI) in industry, leading to an energy use reduction of 5-40%, an increased competitiveness of industry, and increased economic...

New

HP4INDUSTRY – Enhance collaboration between industry and heat pump stakeholders

The HP4INDUSTRY project pairs ambitious climate targets with concrete, replicable process integrated solutions for industrial heating and cooling, enabling cleaner, competitive manufacturing for Europe’s future.

PoSiMem – Periodic organosilica nanofiltration membranes

This project aims to develop robust, reproducible and easy to scale-up approaches for the production of novel nanofiltration (NF) membranes.

FOMM – Forward Osmosis Membrane and Module development

Forward osmosis (FO) is a technology recently developed on academic level, with very few example applications in the market, despite its strong benefits. FO is an energy efficient and effective...

Completed

COSMOS – Organic solvent nanofiltration membranes on low cost ceramic supports

The COSMOS-project found that membrane technology has the potential to replace or supplement current inefficient distillation processes.

ReSolve – Re-use of industrial solvent process streams

Ceramic organic solvent nanofiltration membranes with small pore sizes and high throughputs, as compared to polymeric membranes, will be developed by a novel technology.

Completed

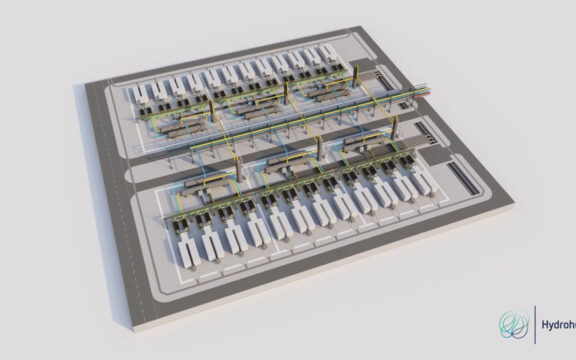

HyScaling – Making better electrolyzers in a better way

HyScaling aims to scale electrolysis capacity up to 5GW by 2030 so the Netherlands can play a key role in the global green hydrogen economy.

Completed

SUPP – Steel Slag Upgrading and PCC Production

The aim of the SUPP project is to create one combined and integrated robust batch process in order to stabilize and upgrade steel slag and neutralize hydrochloric acid. In addition, it...

Completed

Steam and condensate quality

This project focuses on requiering better insights into the distribution and behaviour of conditioning chemicals that is used in their steam-water cycles and condensate polishing. Process industries strive for more...

Completed

WeCare – We Create Awareness & Reduce Energy

The WeCARE project demonstrated the possibilities of Artificial Intelligence technology of EnergQ at a selected number of end users. EnerGQ’s self-learning energy management technology unveiled the excessive energy consumption and with that...

Completed

PTTP – Process Technology Talent Program

PTTP was a talent program for promising HBO students who aim to drive sustainability in the process technology.

Completed

H2-Safety2 – Safety Standardisation of Green Hydrogen Electrolyser Systems

This hydrogen safety project aimed to develop recommendations for standardisation, meeting process safety requirements for large scale water electrolysis. This is an important step to enable a safe, integrated hydrogen-based...

Completed

LEMPLAR – Losses & Emissions in Plastic Recycling

The plastic recycling process today has losses and emissions, such as microplastics, inks and incorrectly sorted plastics. This prevents us of closing the plastic cycle.

Completed

GreenWedge

The GreenWedge project helps SMEs actively market their sustainable technology.

Completed

Probiotics – Low energy living bacterial food formulations

Research towards a novel and generic strategy for probiotics in low energy living bacterial food formulations

Completed

EEMS – Energy Efficient Milky Sprays

Spray drying is a very energy intensive process. EEMS is about energy efficient drying which can lead to 20% energy reduction.

Renewable Building Blocks from Complex and wet waste Streams (ReBBloCS)

The ReBBloCS project aims to develop new circular value chains for the valorisation of complex and mixed waste streams into valuable chemical products.

Completed

CMF – Controlling Multiphase Flow

This Industrial Partnership Programme aims at understanding the rheology of complex emulsions and their stability under flow. While there is much empirical knowledge about emulsion rheology and stability, the microscopic...

Completed

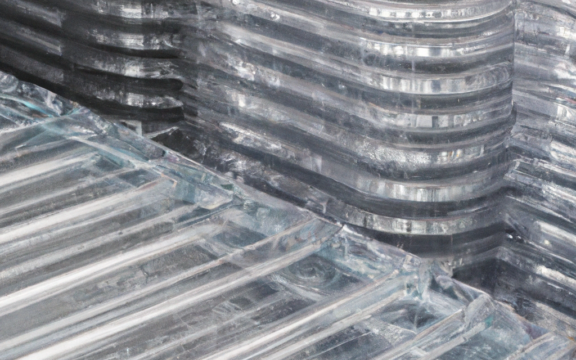

Nanofiltration (EAMS) – Hybrid membranes for organic solvent nanofiltration

Nanofiltration (EAMS) is a project that focusses on finding practical and economical viable membrane materials to be commercially applied.

Completed

CIRCPET – Circular PET trays for perishable food applications

PET trays are currently difficult to recycle. How can we create a fully circular PET tray solution that meets market demands while minimizing environmental impact?

ReValue – Recovery of Valuable minerals with hybrid ceramic membrane crystallization

The ReValue project explores the potential of membrane crystallization, a promising technology to recover valuable compounds from aqueous streams.

Completed

HF2N – High Flux 2D Nanosheet membranes

High Flux 2D Nanosheet membranes to demonstrate and validate the high potential of a new class of inorganic high flux 2D Nanosheet membranes on a practical scale

Recircanol: Circular recovery of ethanol from alkaline-ethanol media at high pH using membrane technology

This project develops nanofiltration membranes and membrane modules for alkaline-alcohol media at high pH for the purification of ethanol and caustic.

CRUISE – Cost Reduction Industrial Heatpumps

CRUISE project aims to develop 50% less expensive heat pump technology that generates heat in an economically feasible way