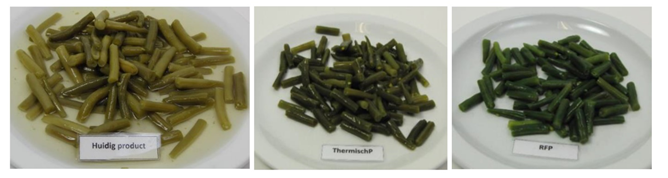

The project Radio Frequent Sterizilation 2 (RFS2) is focused on the development of RF in-pack sterilization of foods. The project is a continuation of the JIP-project Radio Frequent Sterilization (RFS) that was finished in late 2018.

Objectives

This first RFS project (CM-20-08) aimed to develop a fast screening method to determine the effect of different sterilization methods, together with a fully functional RF in-pack pilot. It had the objective to develop a fast screening method to determine the effect of different sterilization methods, together with a fully functional RF in-pack pilot.

Remaining challenges

A few challenges still remained after completion of the RFS project, resulting in this project RFS2 (CM-20-10) with the title “Pilot Radiofrequent In-Pack Steriliseren – Fase 2 – van TRL6 naar TRL 7” (July 2019 – January 2020). Within RFS2 project, the goals are to develop a simulation tool for the RF heating of food products, improve RF field homogeneity and develop a method for 12D validation of foods in RF.

Development of simulation tool

To develop the simulation tool, reliable data on electromagnetic properties of foods was required. Literature data proved not to be sufficient, which necessitated the development of a method to measure the electromagnetic properties of (solid) foods. The method developed provided valuable insights into the dependency of these parameters on temperature, particle size, orientation and so on. The simulation tool combined with the measured data gives insight into the RF power required to sterilize a given food product.

12D validation

For 12D validation, gel particles were developed to be used in RF in-pack trials once inoculated with spores. Unfortunately, trials with inoculated particles did not fit within the project duration and budget.

The RF field homogeneity was investigated and improved in this project by making use of simulations and a few modifications to the original pilot. Positioning of temperature loggers to accurately measure the heating of food trays proved difficult to reproduce. Control of process water and other parameters may improve the homogeneity further.

Further developments on this topic will focus on scale-up to a continuous industrial process with industrial 12D validation, refinement of temperature measurements and development of sustainable packaging suitable for RF treatment.

You might also be interested in

Acknowledgement & partners

This project is co-funded by TKI-E&I with the supplementary grant 'TKI- Toeslag' for Topconsortia for Knowledge and Innovation (TKI’s) of the Ministry of Economic Affairs and Climate Policy.