TEXPOWER – Textile Polycotton Waste Evaluation & Recycling

The TEXPOWER project aims to enable a transparent, circular polycotton textile value chain for a sustainable industry in the Netherlands.

Completed

IMPROVISE – Improved process operation via rigorous simulation models

Improved daily operations of important chemical processes in the Dutch chemical industry through operation technology based on detailed physical models. Incentive Being able to anticipate what a chemical process is...

Completed

Engender: Compact Energy Efficient Dryer

Engender works on an energy efficient drying method of foods. Expected energy savings are estimated up to 30%.

CRUISE – Cost Reduction Industrial Heatpumps

CRUISE project aims to develop 50% less expensive heat pump technology that generates heat in an economically feasible way

Completed

Probiotics – Low energy living bacterial food formulations

Research towards a novel and generic strategy for probiotics in low energy living bacterial food formulations

Completed

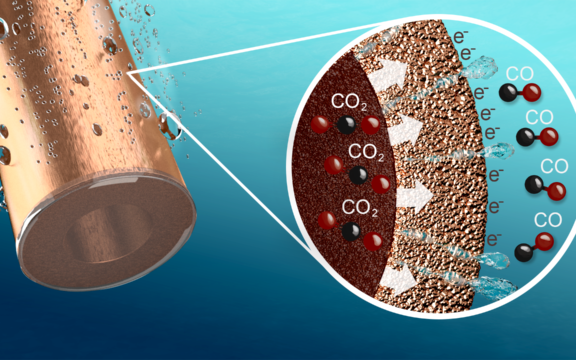

E3C – Electrons to Close the Carbon Cycle

Development and evaluation of tubular and flat porous electrodes for the electrochemical conversion of gasses at ambient temperature. Motivation Renewable electricity (RE) generation is currently growing at a rapid pace....

Completed

ADVANCED PROCESS CONTROL for dynamic operation of a large-scale test electrolyser

In this project we will researching and modelling the impact of variable operation on large-scale test electrolyser performance in green hydrogen.

ELSA – Electrically Switchable Affinity Separation Processes

Exploring the advantages of Electrically Switchable Adsorption (ELSA) membranes in the industrial separation process.

Completed

SAAI – Social Acceptance of AI in Industry

The SAAI project focuses on accelerating the implementation of Artificial Intelligence (AI) in industry, leading to an energy use reduction of 5-40%, an increased competitiveness of industry, and increased economic...

Completed

Provides

The Provides initiative aims to make the paper industry more sustainable by developing Deep Eutectic Solvents (DES).

MilDeWat – Breakthrough Mild Dewatering Technologies

This project will enhance the implementation of mild (energy extensive) dewatering technologies to contribute to industry's energy reduction goals.

PoSiMem – Periodic organosilica nanofiltration membranes

This project aims to develop robust, reproducible and easy to scale-up approaches for the production of novel nanofiltration (NF) membranes.

Odysseus

Goal of this project is to develop a library of complementary techniques for concentrating brines beyond reverse osmosis.

Completed

FreezeCon – Freeze Concentration

Saving energy, improving product quality with freeze concentration as economically feasible bulk dewatering technology. Background Several technologies are available for liquid concentration in the food industry, the most common being...

Completed

Biorefinery Program

Biorefinery enables the production of healthy ingredients and the recovery of valuable components (i.e. proteins) out of process streams.

ReCoVR – Recovery and Circularity of Valuable Resources

ReCoVR designs and develops novel functional materials and technologies to selectively recover high-value molecules.

EPRoTrans – Energy reduction technologies enabling PRotein Transition

Project Energy Efficient Protein Transition (EProTrans) investigates the processing of several mixed plant-based streams to produce plant-based proteins.

SUNSOLr: Electrification of Chemical Conversions

The SUNSOLr project is dedicated to developing technologies for the direct electrification of chemical conversions, focusing on CO2 and H2O/H2 to produce chemicals like CO, CH4, olefins, and methanol.

Completed

ReCYCLE – Electrical bike with durable circular plastic parts

ReCYCLE is a cutting-edge project that combines electric bikes with durable circular plastic parts, pushing the boundaries of innovation in sustainability.

Cascade Recyling of Plastic Film (CaRP)

The CaRP project will find and show realistic cascade recycling routes for packaging film waste to minimise the amount of plastic film waste that is incinerated and to maximise the...

Completed

InReP – An Integrated approach towards Recycling of Plastics

Recycling plastics is one of the biggest challenges the industry is facing today. This projects aims to overcome current challenges.

Completed

COSMOS – Organic solvent nanofiltration membranes on low cost ceramic supports

The COSMOS-project found that membrane technology has the potential to replace or supplement current inefficient distillation processes.

Completed

HyChain – Energy Carriers and Hydrogen Supply Chain

The HyChain project is focused on a strategic understanding of the drivers behind global emergence of future renewable hydrogen value chains.

Completed

DISCO – Downstream ISolation of high-value COmponents

The Downstream ISolation of high-value Components (DISCO) aims to lower the material use and increase the energy-efficiency.