PoSiMem – Periodic organosilica nanofiltration membranes

This project aims to develop robust, reproducible and easy to scale-up approaches for the production of novel nanofiltration (NF) membranes.

Completed

Steam and condensate quality

This project focuses on requiering better insights into the distribution and behaviour of conditioning chemicals that is used in their steam-water cycles and condensate polishing. Process industries strive for more...

SUNSOLr: Electrification of Chemical Conversions

The SUNSOLr project is dedicated to developing technologies for the direct electrification of chemical conversions, focusing on CO2 and H2O/H2 to produce chemicals like CO, CH4, olefins, and methanol.

BEAP – Bundled Early Adaptor Project

BEAP helps SMEs make contact with industries, localize and develop their technologies to suite the specific needs of Dutch industrial partners.

Aramazing

Aramids hold untapped potential in the journey towards sustainability. We can transform these once-disposed materials into a circular value chain, reducing waste, and striving for CO2 neutrality.

Completed

Thin Film Drying

A part of the drying and dewattering program with Thin Film Drying as a new technology for product quality and energy consumption

Completed

LEMPLAR – Losses & Emissions in Plastic Recycling

The plastic recycling process today has losses and emissions, such as microplastics, inks and incorrectly sorted plastics. This prevents us of closing the plastic cycle.

Flexible Efficient Electrification of Industrial Heat Cases

This project will develop innovative process designs solving the efficient flexible electrification challenge.

TEXPOWER – Textile Polycotton Waste Evaluation & Recycling

The TEXPOWER project aims to enable a transparent, circular polycotton textile value chain for a sustainable industry in the Netherlands.

EPRoTrans – Energy reduction technologies enabling PRotein Transition

Project Energy Efficient Protein Transition (EProTrans) investigates the processing of several mixed plant-based streams to produce plant-based proteins.

Completed

Novel Process Routes – Reduction of energy use by novel process routes for food (ProFo)

Several partners are working towards a 50% reduction of energy use developing novel process routes in food processing.

Completed

IMPACCT – Improved process performance by process intensification in centrifugal contactors

Centrifugal contactors, such as RPBs, could provide significant improvement of separation processes in the chemical industry. This technology seems potentially suitable for replacing or debottlenecking current unit operations which suffer...

Completed

Biorefinery Program

Biorefinery enables the production of healthy ingredients and the recovery of valuable components (i.e. proteins) out of process streams.

Completed

StAgglop: Reducing energy use and material loss by better control of agglomeration during spray drying

Project stAgglop aims to improve agglomeration control to contribute to the reduction of emissions for industrial drying systems.

Completed

COMPACT – Pulsed Compression II

The goal of this project was to produce ethylene from methane using pulsed compression technology and to determine the feasibility for industrial applications.

TREPS – Trace Removal Using Electrically Powered Separations

In a circular economy, traces need to be removed to keep the loop clean. TREPS deals with trace removal using electricity.

Completed

Probiotics – Low energy living bacterial food formulations

Research towards a novel and generic strategy for probiotics in low energy living bacterial food formulations

R-ACES – FRamework for Actual Cooperation on Energy on Sites and Parks

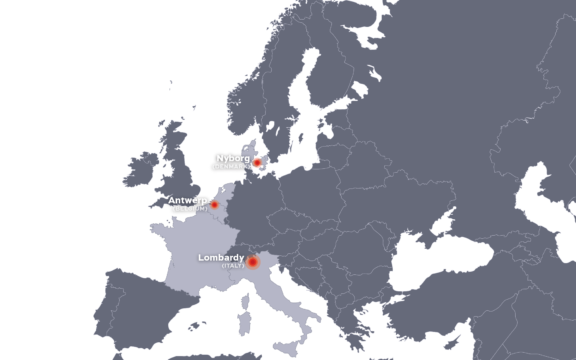

R-ACES aims to turn high-potential, high-impact industrial clusters into eco-regions with at least 10% reduction in emissions in smart energy.

Completed

HF2N – High Flux 2D Nanosheet membranes

High Flux 2D Nanosheet membranes to demonstrate and validate the high potential of a new class of inorganic high flux 2D Nanosheet membranes on a practical scale

ReCYCLE – Electrical bike with durable circular plastic parts

ReCYCLE is a cutting-edge project that combines electric bikes with durable circular plastic parts, pushing the boundaries of innovation in sustainability.

Completed

e-Missi0n MOOI

e-Missi0n developed two technological routes for the emission free production of low-carbon olefins.

ENCORE – nExt geNeration COmpRession hEat pump

This project demonstrates the enhancement of compression heat pump performance by using a pilot scale test unit.

Completed

PROVE IT

PROVE IT is all about the technical feasibility of the production of methanol from CO2 waste gas.

Completed

Hydrohub GigaWatt Scale Electrolyser

We are an important step further towards a Dutch hydrogen economy: the design for an advanced green hydrogen plant at large scale.