Completed

RFS2 – Radio Frequent Sterilization 2

The project Radio Frequent Sterizilation 2 (RFS2) is focused on the development of RF in-pack sterilization of foods. The project is a continuation of the JIP-project Radio Frequent Sterilization (RFS)...

Cascade Recyling of Plastic Film (CaRP)

The CaRP project will find and show realistic cascade recycling routes for packaging film waste to minimise the amount of plastic film waste that is incinerated and to maximise the...

FlexPower: Accelerating industrial electrification for a CO2-neutral future

Industrial electrification is key to achieving the Netherlands’ goal of reducing CO2 emissions by 60% by 2030 and becoming climate-neutral by 2050. The FlexPower project focuses on flexible and efficient...

Completed

Steam and condensate quality

This project focuses on requiering better insights into the distribution and behaviour of conditioning chemicals that is used in their steam-water cycles and condensate polishing. Process industries strive for more...

New

ECONEXT – Enabling protein CONcentrates for EXTrusion

ECONEXT paves the way for a sustainable shift in protein production—one that’s not just better for the planet, but also economically viable and locally rooted.

Bio4Steel

How can biochar — an organic material created by heating wood or other plant material in the absence of oxygen — play a role in replacing fossil coal in the...

Completed

FreezeCon – Freeze Concentration

Saving energy, improving product quality with freeze concentration as economically feasible bulk dewatering technology. Background Several technologies are available for liquid concentration in the food industry, the most common being...

Completed

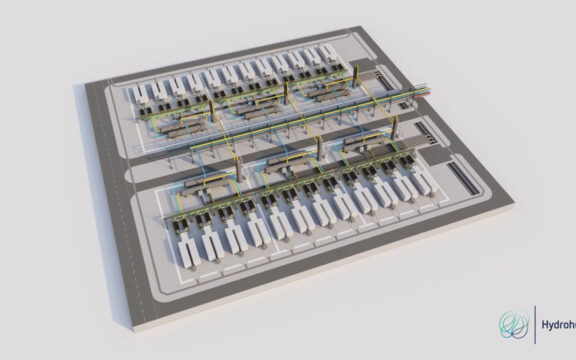

Hydrohub GigaWatt Scale Electrolyser

We are an important step further towards a Dutch hydrogen economy: the design for an advanced green hydrogen plant at large scale.

Completed

RFS – Radio Frequent Sterilization

Heating with Radio Frequent Sterilization (RFS) has large advantages for the product quality.

GAMBA – Green Alloys Modelling Better Approaches

The GAMBA project seeks to reduce the carbon footprint of the iron and steel industry by transitioning from natural gas to hydrogen-based direct reduction (DRI) processes.

Completed

H2-Safety2 – Safety Standardisation of Green Hydrogen Electrolyser Systems

This hydrogen safety project aimed to develop recommendations for standardisation, meeting process safety requirements for large scale water electrolysis. This is an important step to enable a safe, integrated hydrogen-based...

Completed

Novel Process Routes – Reduction of energy use by novel process routes for food (ProFo)

Several partners are working towards a 50% reduction of energy use developing novel process routes in food processing.

Completed

STNF – Solvent Tolerant Nanofiltration and reverse osmosis membranes for the purification of industrial aqueous streams

Many industrial process streams contain water with solvents and other organic components. Such streams need to be purified from these components or need to be treated before further handling. Polymeric...

Completed

Green Hydrogen Inherent Safety Practices on Large Industrial Scale

This project will develop a uniform safety approach and increase awareness of safety for industrial scale electrolysis plants.

Aramazing

Aramids hold untapped potential in the journey towards sustainability. We can transform these once-disposed materials into a circular value chain, reducing waste, and striving for CO2 neutrality.

Completed

ERGO – Energy Reduction by Condition-based Monitoring

Unlocking energy efficiency and fault detection with electrical signal analysis Electric motors and rotating equipment—such as pumps, fans, compressors, and conveyors—consume over 40% of global electricity. However, nearly one-third of...

BEAP – Bundled Early Adaptor Project

BEAP helps SMEs make contact with industries, localize and develop their technologies to suite the specific needs of Dutch industrial partners.

Flexible Efficient Electrification of Industrial Heat Cases

This project will develop innovative process designs solving the efficient flexible electrification challenge.

Completed

ECWRTI – Electrocoagulation for Water Recycling in Textile Industry

The ECWRTI project is about closing the waterloop in the textile industry.

TEXPOWER – Textile Polycotton Waste Evaluation & Recycling

The TEXPOWER project aims to enable a transparent, circular polycotton textile value chain for a sustainable industry in the Netherlands.

Completed

CMF – Controlling Multiphase Flow

This Industrial Partnership Programme aims at understanding the rheology of complex emulsions and their stability under flow. While there is much empirical knowledge about emulsion rheology and stability, the microscopic...

Completed

INSPEC – Integrating sensor based process monitoring and advanced process control

INSPEC quantitatively integrates information from state-of-the-art Process Analytical Technology, process measurements and dynamic process models (data driven or physics-based) into Advanced Process Control. This will induce a step-change with respect to...

Completed

TENMIP – Testing and evaluation of nanofiltration membranes in industrial processes

Make very tight, low swelling NF or RO membranes for organic solvents, test them in process mixtures as present in industry and demonstrate / evaluate their economic feasibility on small...

FOMM – Forward Osmosis Membrane and Module development

Forward osmosis (FO) is a technology recently developed on academic level, with very few example applications in the market, despite its strong benefits. FO is an energy efficient and effective...