SPOT: Sustainable PrOcess heaTing

SPOT (Sustainable PrOcess) aims to reduce the use of fossil energy use for industrial heat with at least 100 PJ/year in 2030.

Completed

TENMIP – Testing and evaluation of nanofiltration membranes in industrial processes

Make very tight, low swelling NF or RO membranes for organic solvents, test them in process mixtures as present in industry and demonstrate / evaluate their economic feasibility on small...

Completed

Steam and condensate quality

This project focuses on requiering better insights into the distribution and behaviour of conditioning chemicals that is used in their steam-water cycles and condensate polishing. Process industries strive for more...

FOMM – Forward Osmosis Membrane and Module development

Forward osmosis (FO) is a technology recently developed on academic level, with very few example applications in the market, despite its strong benefits. FO is an energy efficient and effective...

Sussic – Sustainable treatment of industrial streams

In the Sussic project, atomic layer deposition (ALD) will be used for the development of SiC NF membranes, allowing treatment of challenging industrial streams.

Completed

BRECSIT – Bio-based REsin CompoSIte Technologies

Plantics-GX composites can replace conventional, fossil-based plastic composites.

PlastiCycle 4.0 – Revolutionizing smart formulation in mechanical recycling for closing the circular value chain

Transforming plastic waste into high-quality recycled plastics. Discover how PlastiCycle 4.0 is revolutionizing mechanical recycling.

Completed

C2V – Carbon2Value

Innovative CO2 separation technology aims to reduce emissions in steel industry. This project revolves around an innovative technology with the potential to reduce CO2 emissions across the major energy intensive...

New

AutoPlastic: Shaping the Future of Automotive and Plastic Recycling

As the automotive industry faces new recycling legislation, the AutoPlastic project leads the way in boosting car plastic recycling. It helps the Dutch automotive sector stay ahead by developing solutions...

Completed

EEMS – Energy Efficient Milky Sprays

Spray drying is a very energy intensive process. EEMS is about energy efficient drying which can lead to 20% energy reduction.

Completed

CMF – Controlling Multiphase Flow

This Industrial Partnership Programme aims at understanding the rheology of complex emulsions and their stability under flow. While there is much empirical knowledge about emulsion rheology and stability, the microscopic...

Completed

PTTP – Process Technology Talent Program

PTTP was a talent program for promising HBO students who aim to drive sustainability in the process technology.

Completed

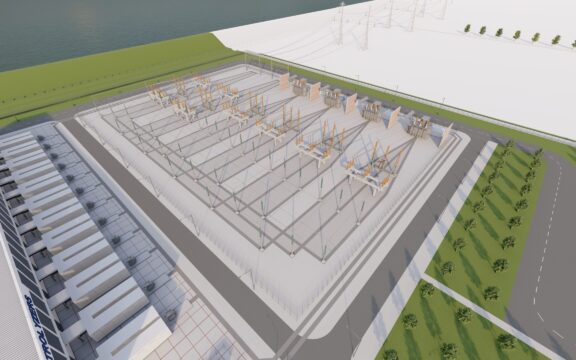

Hydrohub GigaWatt Scale Electrolyser

We are an important step further towards a Dutch hydrogen economy: the design for an advanced green hydrogen plant at large scale.

EPRoTrans – Energy reduction technologies enabling PRotein Transition

Project Energy Efficient Protein Transition (EProTrans) investigates the processing of several mixed plant-based streams to produce plant-based proteins.

Completed

Preciouspitation

Obtaining process water out of rain from own roof with high energy saving potential compared to current processes. Motivation and Scope Rainwater is already chemically very pure. Only some evaporated...

ELSA – Electrically Switchable Affinity Separation Processes

Exploring the advantages of Electrically Switchable Adsorption (ELSA) membranes in the industrial separation process.

Completed

WeCare – We Create Awareness & Reduce Energy

The WeCARE project demonstrated the possibilities of Artificial Intelligence technology of EnergQ at a selected number of end users. EnerGQ’s self-learning energy management technology unveiled the excessive energy consumption and with that...

Completed

ECWRTI – Electrocoagulation for Water Recycling in Textile Industry

The ECWRTI project is about closing the waterloop in the textile industry.

Completed

DC-DC converters – Green GW Hydrogen Plant

In this project we investigate DC-DC connections for large-scale green hydrogen plants to address space constraints, reduce investment costs (up to 25%), and mitigate significant electricity losses compared to traditional...

New

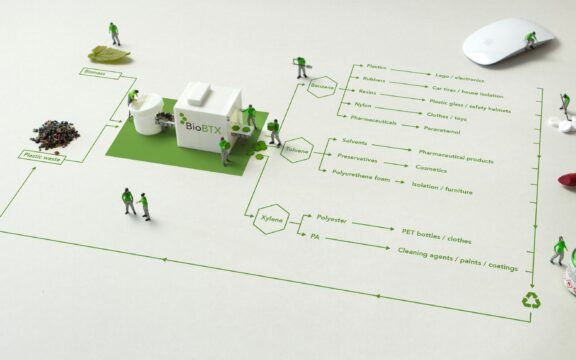

Circular Aromatics – Turning Waste into High-Value Circular Plastics

As the world moves toward net-zero carbon goals, the demand for sustainable materials is rapidly increasing. Plastics, essential in countless applications, must evolve to meet the demands of a circular,...

Completed

Biorefinery Program

Biorefinery enables the production of healthy ingredients and the recovery of valuable components (i.e. proteins) out of process streams.

The Heat Is On

The Heat is On aims to make processes for dewatering, drying and heat integration more efficient.

Completed

Novel Process Routes – Reduction of energy use by novel process routes for food (ProFo)

Several partners are working towards a 50% reduction of energy use developing novel process routes in food processing.

Completed

IMPROVISE – Improved process operation via rigorous simulation models

Improved daily operations of important chemical processes in the Dutch chemical industry through operation technology based on detailed physical models. Incentive Being able to anticipate what a chemical process is...