Completed

Amazing – Additive Manufacturing for Zero-Emission Innovative Green Chemistry

Amazing is about replacing large-scale high-temperature cracking processes with electrically driven thermocatalytic dehydrogenation.

Completed

GreenWedge

The GreenWedge project helps SMEs actively market their sustainable technology.

Completed

Steam and condensate quality

This project focuses on requiering better insights into the distribution and behaviour of conditioning chemicals that is used in their steam-water cycles and condensate polishing. Process industries strive for more...

Completed

HF2N – High Flux 2D Nanosheet membranes

High Flux 2D Nanosheet membranes to demonstrate and validate the high potential of a new class of inorganic high flux 2D Nanosheet membranes on a practical scale

ReSolve – Re-use of industrial solvent process streams

Ceramic organic solvent nanofiltration membranes with small pore sizes and high throughputs, as compared to polymeric membranes, will be developed by a novel technology.

Completed

HyScaling – Making better electrolyzers in a better way

HyScaling aims to scale electrolysis capacity up to 5GW by 2030 so the Netherlands can play a key role in the global green hydrogen economy.

Completed

S2C – Steel2Chemicals

The project Steel2Chemicals develops a closed value chain in which CO from steel production is used as feedstock for the chemical industry.

Completed

CIRCPET – Circular PET trays for perishable food applications

PET trays are currently difficult to recycle. How can we create a fully circular PET tray solution that meets market demands while minimizing environmental impact?

FOMM – Forward Osmosis Membrane and Module development

Forward osmosis (FO) is a technology recently developed on academic level, with very few example applications in the market, despite its strong benefits. FO is an energy efficient and effective...

Completed

WeCare – We Create Awareness & Reduce Energy

The WeCARE project demonstrated the possibilities of Artificial Intelligence technology of EnergQ at a selected number of end users. EnerGQ’s self-learning energy management technology unveiled the excessive energy consumption and with that...

Completed

ECWRTI – Electrocoagulation for Water Recycling in Textile Industry

The ECWRTI project is about closing the waterloop in the textile industry.

Aramazing

Aramids hold untapped potential in the journey towards sustainability. We can transform these once-disposed materials into a circular value chain, reducing waste, and striving for CO2 neutrality.

Completed

IoF – Internet of Food

The Internet of Food (IoF) project defines the sharing of data and models in order to improve sensing systems in food production.

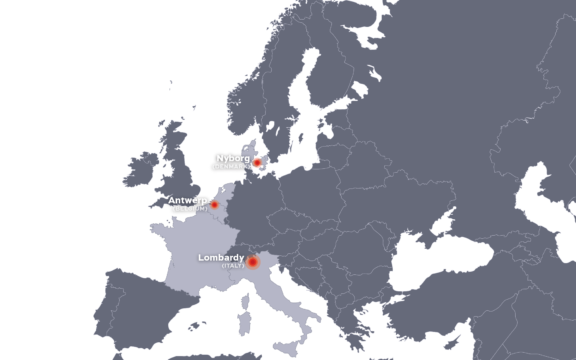

R-ACES – FRamework for Actual Cooperation on Energy on Sites and Parks

R-ACES aims to turn high-potential, high-impact industrial clusters into eco-regions with at least 10% reduction in emissions in smart energy.

Completed

RMZD – Radial Multi-Zone Drying

The Radial Multi-zone Dryer (RMD) project investigates new type of spray dryer for premium product properties and low specific energy consumption.

Completed

AIDA – Accelerate the Integration of Digitalisation Acceptation

The AIDA project performs research towards predictive capabilities and integration of digital technologies at the various levels of individual processes.

ReCoVR – Recovery and Circularity of Valuable Resources

ReCoVR designs and develops novel functional materials and technologies to selectively recover high-value molecules.

Completed

RiConfigure

RiConfigure is about involving a diverse group of actors in society’s innovation team.

Demonstration Polymer Heat Exchanger

The goal of this project is to demonstrate the innovative technologies as developed by HeatMatrix in the industrial process in the BioMCN factories. On the one hand this would result...

Completed

PTTP – Process Technology Talent Program

PTTP was a talent program for promising HBO students who aim to drive sustainability in the process technology.

Cascade Recyling of Plastic Film (CaRP)

The CaRP project will find and show realistic cascade recycling routes for packaging film waste to minimise the amount of plastic film waste that is incinerated and to maximise the...

SUNSOLr: Electrification of Chemical Conversions

The SUNSOLr project is dedicated to developing technologies for the direct electrification of chemical conversions, focusing on CO2 and H2O/H2 to produce chemicals like CO, CH4, olefins, and methanol.

Completed

ERGO – Energy Reduction by Condition-based Monitoring

Unlocking energy efficiency and fault detection with electrical signal analysis Electric motors and rotating equipment—such as pumps, fans, compressors, and conveyors—consume over 40% of global electricity. However, nearly one-third of...

Completed

INSPEC – Integrating sensor based process monitoring and advanced process control

INSPEC quantitatively integrates information from state-of-the-art Process Analytical Technology, process measurements and dynamic process models (data driven or physics-based) into Advanced Process Control. This will induce a step-change with respect to...