Completed

Fine Biofuels

In the Netherlands there is a total quantity of 1 million tons of roadside grass which must be mowed at least twice a year to keep the roadside banks safe....

Completed

RFS – Radio Frequent Sterilization

Heating with Radio Frequent Sterilization (RFS) has large advantages for the product quality.

Completed

Smart Maintenance Skillslab

In a Smart Maintenance Skillslab industry and educational institutions can collaborate on new forms of education to solve shortage on the labor market.

Completed

GRIP on Drying

This project investigates how inline sensors can help improving product quality and efficiency.

Completed

COMPRESORP

COMPRESORP focuses on upgrading low temperature waste water streams of separation processes with compression resorption heat pumps.

Completed

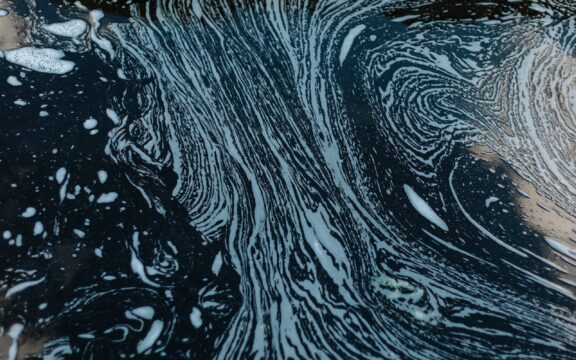

SiC – Silicon Carbide membranes for innovative oil-in-water separations

This project investigates the behavior of silicon carbide membranes in pilot trials. These determine fouling, cleaning options, cleaning frequency and the consequences for the long term performance and economics. Test...

Completed

HyChain – Energy Carriers and Hydrogen Supply Chain

The HyChain project is focused on a strategic understanding of the drivers behind global emergence of future renewable hydrogen value chains.

Completed

Next Level Solid Oxide Electrolysis

Solid Oxide Electrolysis is a technology with great potential for large-scale green hydrogen production by water electrolysis. This project explores the upscaling potential of SOEC.

FLEXSTEAM – Development of heat storage for industrial steam

The FLEXSTEAM project aims to improve the way we can store and re-use thermal energy by using so called ‘Phase Changing Materials’ (PCMs). To achieve a fully circular economy we...

Completed

EEMS – Energy Efficient Milky Sprays

Spray drying is a very energy intensive process. EEMS is about energy efficient drying which can lead to 20% energy reduction.

Completed

ADVANCED PROCESS CONTROL for dynamic operation of a large-scale test electrolyser

In this project we will researching and modelling the impact of variable operation on large-scale test electrolyser performance in green hydrogen.

Completed

C2V – Carbon2Value

Innovative CO2 separation technology aims to reduce emissions in steel industry. This project revolves around an innovative technology with the potential to reduce CO2 emissions across the major energy intensive...

Completed

Thin Film Drying

A part of the drying and dewattering program with Thin Film Drying as a new technology for product quality and energy consumption

Completed

Carbon Transition Model

The Carbon Transition Model is a simulation model to explore ways to reduce emissions and increase carbon circularity.

Completed

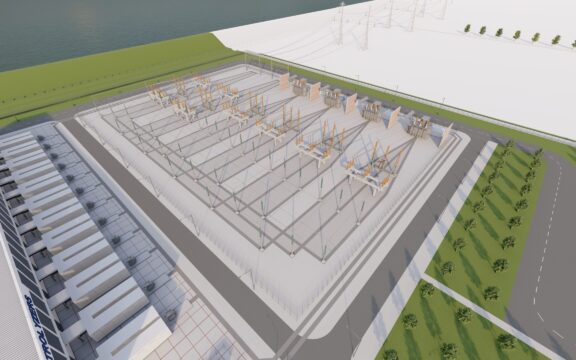

DC-DC converters – Green GW Hydrogen Plant

In this project we investigate DC-DC connections for large-scale green hydrogen plants to address space constraints, reduce investment costs (up to 25%), and mitigate significant electricity losses compared to traditional...

ReValue – Recovery of Valuable minerals with hybrid ceramic membrane crystallization

The ReValue project explores the potential of membrane crystallization, a promising technology to recover valuable compounds from aqueous streams.

Completed

Nanofiltration (EAMS) – Hybrid membranes for organic solvent nanofiltration

Nanofiltration (EAMS) is a project that focusses on finding practical and economical viable membrane materials to be commercially applied.

Completed

PTTP – Process Technology Talent Program

PTTP was a talent program for promising HBO students who aim to drive sustainability in the process technology.

TREPS – Trace Removal Using Electrically Powered Separations

In a circular economy, traces need to be removed to keep the loop clean. TREPS deals with trace removal using electricity.

Completed

WeCare – We Create Awareness & Reduce Energy

The WeCARE project demonstrated the possibilities of Artificial Intelligence technology of EnergQ at a selected number of end users. EnerGQ’s self-learning energy management technology unveiled the excessive energy consumption and with that...

ENCORE – nExt geNeration COmpRession hEat pump

This project demonstrates the enhancement of compression heat pump performance by using a pilot scale test unit.

Completed

Engender: Compact Energy Efficient Dryer

Engender works on an energy efficient drying method of foods. Expected energy savings are estimated up to 30%.

Completed

BRECSIT – Bio-based REsin CompoSIte Technologies

Plantics-GX composites can replace conventional, fossil-based plastic composites.

Completed

Towards improved circularity of polyolefin-based packaging

This project aims at improved circularity of polyolefin-based packaging materials through overcoming technological hurdles.