Completed

PINcHED – Process INtegrated HEat pump Drying

This project creates greenfield conceptual design packages for contact and convective drying of a full scale. In addition, it focuses on establishing a fully heat pump integrated drying process, including...

Completed

Nanofiltration (EAMS) – Hybrid membranes for organic solvent nanofiltration

Nanofiltration (EAMS) is a project that focusses on finding practical and economical viable membrane materials to be commercially applied.

LESSON – Oil free compressor for ammonia based high temperature heat pumps

Wet compression allows for close to isothermal conditions during compression resulting in higher compression isentropic efficiencies. It further prevents operation in the superheating zone of the working fluids of heat...

Completed

RFS2 – Radio Frequent Sterilization 2

The project Radio Frequent Sterizilation 2 (RFS2) is focused on the development of RF in-pack sterilization of foods. The project is a continuation of the JIP-project Radio Frequent Sterilization (RFS)...

ENCORE – nExt geNeration COmpRession hEat pump

This project demonstrates the enhancement of compression heat pump performance by using a pilot scale test unit.

PoSiMem – Periodic organosilica nanofiltration membranes

This project aims to develop robust, reproducible and easy to scale-up approaches for the production of novel nanofiltration (NF) membranes.

Completed

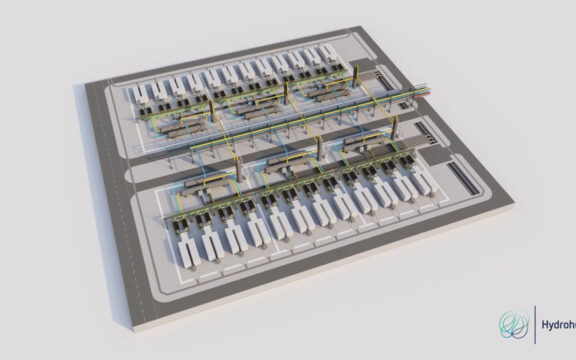

ADVANCED PROCESS CONTROL for dynamic operation of a large-scale test electrolyser

In this project we will researching and modelling the impact of variable operation on large-scale test electrolyser performance in green hydrogen.

Completed

H2-Safety2 – Safety Standardisation of Green Hydrogen Electrolyser Systems

This hydrogen safety project aimed to develop recommendations for standardisation, meeting process safety requirements for large scale water electrolysis. This is an important step to enable a safe, integrated hydrogen-based...

Completed

HF2N – High Flux 2D Nanosheet membranes

High Flux 2D Nanosheet membranes to demonstrate and validate the high potential of a new class of inorganic high flux 2D Nanosheet membranes on a practical scale

Cascade Recyling of Plastic Film (CaRP)

The CaRP project will find and show realistic cascade recycling routes for packaging film waste to minimise the amount of plastic film waste that is incinerated and to maximise the...

GAMBA – Green Alloys Modelling Better Approaches

The GAMBA project seeks to reduce the carbon footprint of the iron and steel industry by transitioning from natural gas to hydrogen-based direct reduction (DRI) processes.

Demonstration Polymer Heat Exchanger

The goal of this project is to demonstrate the innovative technologies as developed by HeatMatrix in the industrial process in the BioMCN factories. On the one hand this would result...

Completed

EEMS – Energy Efficient Milky Sprays

Spray drying is a very energy intensive process. EEMS is about energy efficient drying which can lead to 20% energy reduction.

Bio4Steel

How can biochar — an organic material created by heating wood or other plant material in the absence of oxygen — play a role in replacing fossil coal in the...

Completed

COSMOS – Organic solvent nanofiltration membranes on low cost ceramic supports

The COSMOS-project found that membrane technology has the potential to replace or supplement current inefficient distillation processes.

New

Ammonia to Power

The Ammonia to Power project explores the techno-economic potential of ammonia powered electricity generation.

Completed

RiConfigure

RiConfigure is about involving a diverse group of actors in society’s innovation team.

Completed

InReP – An Integrated approach towards Recycling of Plastics

Recycling plastics is one of the biggest challenges the industry is facing today. This projects aims to overcome current challenges.

Renewable Building Blocks from Complex and wet waste Streams (ReBBloCS)

The ReBBloCS project aims to develop new circular value chains for the valorisation of complex and mixed waste streams into valuable chemical products.

Completed

Plasma Conversions

Industrial ammonia production is energy intensive and has a huge footprint. A plasma integrated water electrolyser provides an ecologically clean alternative process to Haber-Bosch.

SPOT: Sustainable PrOcess heaTing

SPOT (Sustainable PrOcess) aims to reduce the use of fossil energy use for industrial heat with at least 100 PJ/year in 2030.

Completed

HOPy – Headstart on pyrolysis

HOPy wants to find a solution that mitigates the environmental impact of plastic waste and taps into its potential as a resource for creating new materials.

Completed

Towards improved circularity of polyolefin-based packaging

This project aims at improved circularity of polyolefin-based packaging materials through overcoming technological hurdles.

Completed

SiC – Silicon Carbide membranes for innovative oil-in-water separations

This project investigates the behavior of silicon carbide membranes in pilot trials. These determine fouling, cleaning options, cleaning frequency and the consequences for the long term performance and economics. Test...