Completed

COSMOS – Organic solvent nanofiltration membranes on low cost ceramic supports

The COSMOS-project found that membrane technology has the potential to replace or supplement current inefficient distillation processes.

Completed

Biorefinery Program

Biorefinery enables the production of healthy ingredients and the recovery of valuable components (i.e. proteins) out of process streams.

Completed

COLFILM – Collapsing Films in Emulsions

In this project computer simulations are used to reveal the impact of a crucial underlying phenomenon: little waves on the surface of droplets that can suddenly grow and thus accelerate...

Completed

RFS2 – Radio Frequent Sterilization 2

The project Radio Frequent Sterizilation 2 (RFS2) is focused on the development of RF in-pack sterilization of foods. The project is a continuation of the JIP-project Radio Frequent Sterilization (RFS)...

Completed

IoF – Internet of Food

The Internet of Food (IoF) project defines the sharing of data and models in order to improve sensing systems in food production.

Completed

Plasma Conversions

Industrial ammonia production is energy intensive and has a huge footprint. A plasma integrated water electrolyser provides an ecologically clean alternative process to Haber-Bosch.

Bio4Steel

How can biochar — an organic material created by heating wood or other plant material in the absence of oxygen — play a role in replacing fossil coal in the...

Completed

Measurements 4 Management

Measurement 4 Management (M4M) focused on applying data-driven decision-making in the process industry, by combining artificial intelligence (AI) with the domain knowledge of process engineers.

PoSiMem – Periodic organosilica nanofiltration membranes

This project aims to develop robust, reproducible and easy to scale-up approaches for the production of novel nanofiltration (NF) membranes.

Completed

Preciouspitation

Obtaining process water out of rain from own roof with high energy saving potential compared to current processes. Motivation and Scope Rainwater is already chemically very pure. Only some evaporated...

ReCYCLE – Electrical bike with durable circular plastic parts

ReCYCLE is a cutting-edge project that combines electric bikes with durable circular plastic parts, pushing the boundaries of innovation in sustainability.

Completed

Probiotics – Low energy living bacterial food formulations

Research towards a novel and generic strategy for probiotics in low energy living bacterial food formulations

PlastiCycle 4.0 – Revolutionizing smart formulation in mechanical recycling for closing the circular value chain

Transforming plastic waste into high-quality recycled plastics. Discover how PlastiCycle 4.0 is revolutionizing mechanical recycling.

Completed

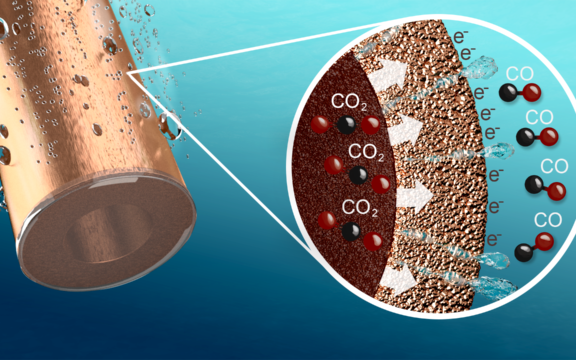

E3C – Electrons to Close the Carbon Cycle

Development and evaluation of tubular and flat porous electrodes for the electrochemical conversion of gasses at ambient temperature. Motivation Renewable electricity (RE) generation is currently growing at a rapid pace....

Completed

Hydrohub GigaWatt Scale Electrolyser

We are an important step further towards a Dutch hydrogen economy: the design for an advanced green hydrogen plant at large scale.

ENCORE – nExt geNeration COmpRession hEat pump

This project demonstrates the enhancement of compression heat pump performance by using a pilot scale test unit.

Completed

HyScaling – Making better electrolyzers in a better way

HyScaling aims to scale electrolysis capacity up to 5GW by 2030 so the Netherlands can play a key role in the global green hydrogen economy.

Completed

Amazing – Additive Manufacturing for Zero-Emission Innovative Green Chemistry

Amazing is about replacing large-scale high-temperature cracking processes with electrically driven thermocatalytic dehydrogenation.

Completed

GRIP on Drying

This project investigates how inline sensors can help improving product quality and efficiency.

Completed

TENMIP – Testing and evaluation of nanofiltration membranes in industrial processes

Make very tight, low swelling NF or RO membranes for organic solvents, test them in process mixtures as present in industry and demonstrate / evaluate their economic feasibility on small...

Hydrohub MegaWatt Test Center

This project covers the design, realization and exploration of the Hydrohub MegaWatt Test Center at the Zernike Campus in Groningen.

Completed

ECWRTI – Electrocoagulation for Water Recycling in Textile Industry

The ECWRTI project is about closing the waterloop in the textile industry.

Completed

PROVE IT

PROVE IT is all about the technical feasibility of the production of methanol from CO2 waste gas.

Completed

Smart Maintenance Skillslab

In a Smart Maintenance Skillslab industry and educational institutions can collaborate on new forms of education to solve shortage on the labor market.