Odysseus

Goal of this project is to develop a library of complementary techniques for concentrating brines beyond reverse osmosis.

Completed

PTTP – Process Technology Talent Program

PTTP was a talent program for promising HBO students who aim to drive sustainability in the process technology.

Completed

CMF – Controlling Multiphase Flow

This Industrial Partnership Programme aims at understanding the rheology of complex emulsions and their stability under flow. While there is much empirical knowledge about emulsion rheology and stability, the microscopic...

Completed

Methanol, the LOGIC Choice!

The LOGIC project scales-up the Liquid-Out Gas-In Concept reactor for methanol synthesis from CO2 and sustainable hydrogen.

Completed

Next Level Solid Oxide Electrolysis

Solid Oxide Electrolysis is a technology with great potential for large-scale green hydrogen production by water electrolysis. This project explores the upscaling potential of SOEC.

EBI – Engineering Business Intelligence

The EBI project uses data collection, data analytics and data visualization to reduce energy usage in existing processes by 5-25%.

TEXPOWER – Textile Polycotton Waste Evaluation & Recycling

The TEXPOWER project aims to enable a transparent, circular polycotton textile value chain for a sustainable industry in the Netherlands.

FOMM – Forward Osmosis Membrane and Module development

Forward osmosis (FO) is a technology recently developed on academic level, with very few example applications in the market, despite its strong benefits. FO is an energy efficient and effective...

DRAGONS Egg – Increasing energy efficiency by steering DRoplet AGglomeratiON in Spray dryers

The DRAGONS Egg-project aims to unravel the dynamics of atomisation behaviour in drying and agglomeration of the droplet.

Flexible Efficient Electrification of Industrial Heat Cases

This project will develop innovative process designs solving the efficient flexible electrification challenge.

Completed

STNF – Solvent Tolerant Nanofiltration and reverse osmosis membranes for the purification of industrial aqueous streams

Many industrial process streams contain water with solvents and other organic components. Such streams need to be purified from these components or need to be treated before further handling. Polymeric...

FlexPower: Accelerating industrial electrification for a CO2-neutral future

Industrial electrification is key to achieving the Netherlands’ goal of reducing CO2 emissions by 60% by 2030 and becoming climate-neutral by 2050. The FlexPower project focuses on flexible and efficient...

Completed

ISRO – Implementation of Solvent Recovery in edible Oil

The ISRO project delivers a proof-of-principle of organic solvent nanofiltration-based solvent recovery for two cases. The first case is an integration of OSN with the current distillation process at IOI...

STARBATCH- Sodium Tetra chloro Aluminate Recyclable BATtery CHemicals

Storage of electricity will play a major role in the energy transition. Lithium-based batteries are now being produced on a large scale, but require expensive resources that are not widely...

Completed

EEMS – Energy Efficient Milky Sprays

Spray drying is a very energy intensive process. EEMS is about energy efficient drying which can lead to 20% energy reduction.

Completed

InReP – An Integrated approach towards Recycling of Plastics

Recycling plastics is one of the biggest challenges the industry is facing today. This projects aims to overcome current challenges.

Renewable Building Blocks from Complex and wet waste Streams (ReBBloCS)

The ReBBloCS project aims to develop new circular value chains for the valorisation of complex and mixed waste streams into valuable chemical products.

New

RePlaCE – Recycling of Plastics from Cars and Electronic Equipment

In this project we accelerate recycling of high‑quality engineering plastics from cars and electronic equipment.

FLEXSTEAM – Development of heat storage for industrial steam

The FLEXSTEAM project aims to improve the way we can store and re-use thermal energy by using so called ‘Phase Changing Materials’ (PCMs). To achieve a fully circular economy we...

ECONEXT – Enabling protein CONcentrates for EXTrusion

ECONEXT paves the way for a sustainable shift in protein production—one that’s not just better for the planet, but also economically viable and locally rooted.

Fingerprint 2 Footprint

Fingerprint 2 Footprint translates chemical fingerprint measurements inside and near chemical processes to reduce environmental footprints, while retaining or improving process economy and consistency.

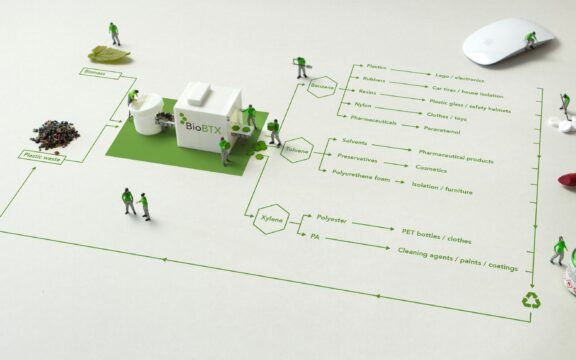

Circular Aromatics – Turning Waste into High-Value Circular Plastics

As the world moves toward net-zero carbon goals, the demand for sustainable materials is rapidly increasing. Plastics, essential in countless applications, must evolve to meet the demands of a circular,...

MilDeWat – Breakthrough Mild Dewatering Technologies

This project will enhance the implementation of mild (energy extensive) dewatering technologies to contribute to industry's energy reduction goals.

SUNSOLr: Electrification of Chemical Conversions

The SUNSOLr project is dedicated to developing technologies for the direct electrification of chemical conversions, focusing on CO2 and H2O/H2 to produce chemicals like CO, CH4, olefins, and methanol.