ECONEXT – Enabling protein CONcentrates for EXTrusion

ECONEXT paves the way for a sustainable shift in protein production—one that’s not just better for the planet, but also economically viable and locally rooted.

BEAP – Bundled Early Adaptor Project

BEAP helps SMEs make contact with industries, localize and develop their technologies to suite the specific needs of Dutch industrial partners.

Completed

COMPRESORP

COMPRESORP focuses on upgrading low temperature waste water streams of separation processes with compression resorption heat pumps.

Completed

Nanofiltration (EAMS) – Hybrid membranes for organic solvent nanofiltration

Nanofiltration (EAMS) is a project that focusses on finding practical and economical viable membrane materials to be commercially applied.

PoSiMem – Periodic organosilica nanofiltration membranes

This project aims to develop robust, reproducible and easy to scale-up approaches for the production of novel nanofiltration (NF) membranes.

Completed

S2C – Steel2Chemicals

The project Steel2Chemicals develops a closed value chain in which CO from steel production is used as feedstock for the chemical industry.

FOMM – Forward Osmosis Membrane and Module development

Forward osmosis (FO) is a technology recently developed on academic level, with very few example applications in the market, despite its strong benefits. FO is an energy efficient and effective...

Completed

Green Hydrogen Inherent Safety Practices on Large Industrial Scale

This project will develop a uniform safety approach and increase awareness of safety for industrial scale electrolysis plants.

Completed

SUPP – Steel Slag Upgrading and PCC Production

The aim of the SUPP project is to create one combined and integrated robust batch process in order to stabilize and upgrade steel slag and neutralize hydrochloric acid. In addition, it...

COMTA – COMpact modular Thermo Acoustic heat pump

To further develop the compact electrically driven thermoacoustic heat (TA) pump technology and to prepare for technical demonstration on full scale. The industry is a large consumer of energy and...

Aramazing

Aramids hold untapped potential in the journey towards sustainability. We can transform these once-disposed materials into a circular value chain, reducing waste, and striving for CO2 neutrality.

PlastiCycle 4.0 – Revolutionizing smart formulation in mechanical recycling for closing the circular value chain

Transforming plastic waste into high-quality recycled plastics. Discover how PlastiCycle 4.0 is revolutionizing mechanical recycling.

Completed

HOPy – Headstart on pyrolysis

HOPy wants to find a solution that mitigates the environmental impact of plastic waste and taps into its potential as a resource for creating new materials.

Completed

Methanol, the LOGIC Choice!

The LOGIC project scales-up the Liquid-Out Gas-In Concept reactor for methanol synthesis from CO2 and sustainable hydrogen.

Completed

ISRO – Implementation of Solvent Recovery in edible Oil

The ISRO project delivers a proof-of-principle of organic solvent nanofiltration-based solvent recovery for two cases. The first case is an integration of OSN with the current distillation process at IOI...

Completed

COMPACT – Pulsed Compression II

The goal of this project was to produce ethylene from methane using pulsed compression technology and to determine the feasibility for industrial applications.

Completed

COLFILM – Collapsing Films in Emulsions

In this project computer simulations are used to reveal the impact of a crucial underlying phenomenon: little waves on the surface of droplets that can suddenly grow and thus accelerate...

Completed

Engender: Compact Energy Efficient Dryer

Engender works on an energy efficient drying method of foods. Expected energy savings are estimated up to 30%.

CRUISE – Cost Reduction Industrial Heatpumps

CRUISE project aims to develop 50% less expensive heat pump technology that generates heat in an economically feasible way

Odysseus

Goal of this project is to develop a library of complementary techniques for concentrating brines beyond reverse osmosis.

Completed

Towards improved circularity of polyolefin-based packaging

This project aims at improved circularity of polyolefin-based packaging materials through overcoming technological hurdles.

GAMBA – Green Alloys Modelling Better Approaches

The GAMBA project seeks to reduce the carbon footprint of the iron and steel industry by transitioning from natural gas to hydrogen-based direct reduction (DRI) processes.

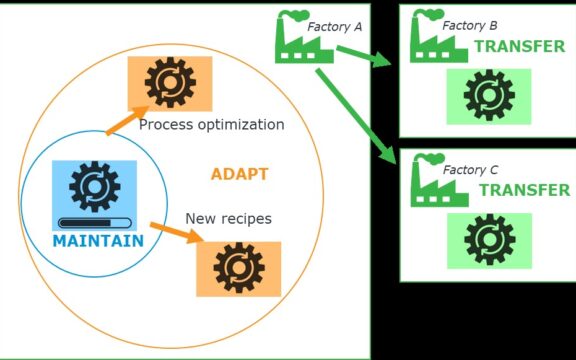

CareFree Models for real-time decision-making

Carefree Models puts process model maintenance, adaptation and transfer into an integrated, automated, and predictive framework that quantifies and reduces the overall resources required to sustain process predictivity and resulting...

Completed

ReCYCLE – Electrical bike with durable circular plastic parts

ReCYCLE is a cutting-edge project that combines electric bikes with durable circular plastic parts, pushing the boundaries of innovation in sustainability.