Green hydrogen is a versatile and clean energy source that holds the potential to power our world. When used as a fuel, hydrogen releases water vapour instead of CO2, making it an attractive alternative to fossil fuels. Therefore, hydrogen plays a crucial role in the pursuit of a CO2-free industrial sector.

As the lightest and most abundant element in the universe, hydrogen can be produced from a variety of sources, including natural gas, water, and renewable energy sources like wind and solar. At the Institute for Sustainable Process Technology (ISPT) in Amersfoort, the focus lies on the production of green hydrogen and the prospective role of hydrogen in a sustainable Dutch industry.

Let’s take a deep dive into hydrogen as a clean energy source.

Table of contents

1. What is (green) hydrogen?

In short:

- Hydrogen is an invisible, odourless and highly flammable gas

- Hydrogen atoms are the most abundant, lightest and smallest molecules on this earth

- It always occurs in combination with other elements, such as in water (H2O)

- To use as a fuel we must first split the H2O into H (hydrogen) and oxygen (O)

- This can be done with green energy (green hydrogen) or with fossil energy (grey hydrogen)

So, hydrogen is produced, unlike natural gas and oil, which are mined. It is thus a man-made product.

Importantly, when hydrogen reconnects with oxygen after fission, electricity is released meaning it can serve as a type of clean fuel.

2. Electrolysis: how hydrogen is produced

To produce hydrogen you need a process called electrolysis. This involves splitting the H and O molecule using electricity. That electricity can come from different sources, either fossil fuels or renewables.

So, if we want a more sustainable society, the production methods and energy sources are key elements.

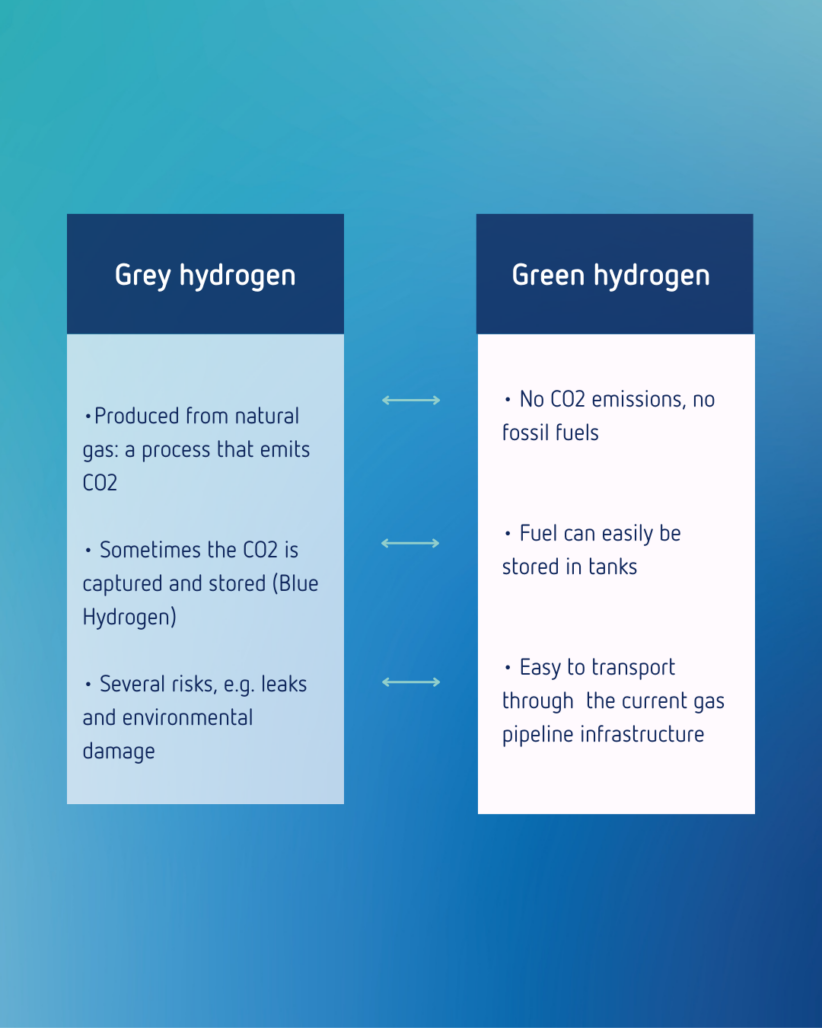

Grey and blue hydrogen

Grey hydrogen is produced by converting natural gas with steam and extreme pressure, resulting in hydrogen and CO2 emissions. Blue hydrogen is produced the same way, but the CO2 is stored underground instead of being emitted. It can reduce CO2 emissions in the short term and serves as a transition fuel towards green hydrogen. However, there are risks like leaks and environmental damage, which can be addressed through CCS or CO2 absorption in greenhouses.

Green hydrogen

Green hydrogen is produced using green electricity sourced from solar and wind energy, making it a sustainable alternative.

Advantage of green hydrogen

One significant advantage of green hydrogen is that it generates no CO2 emissions and relies entirely on renewable energy sources, eliminating the use of fossil fuels. As a clean fuel, green hydrogen is highly efficient and can be easily stored in tanks for future use. Moreover, its compatibility with the existing gas pipeline infrastructure allows for convenient transportation and distribution, facilitating its integration into the energy market.

Next to grey, blue and green hydrogen, there is also:

- Black hydrogen = made with coal

- Turquoise hydrogen = also made with natural gas / methane – but different technology (pyrolysis)

- Purple hydrogen = made with nuclear power – no CO2 is released

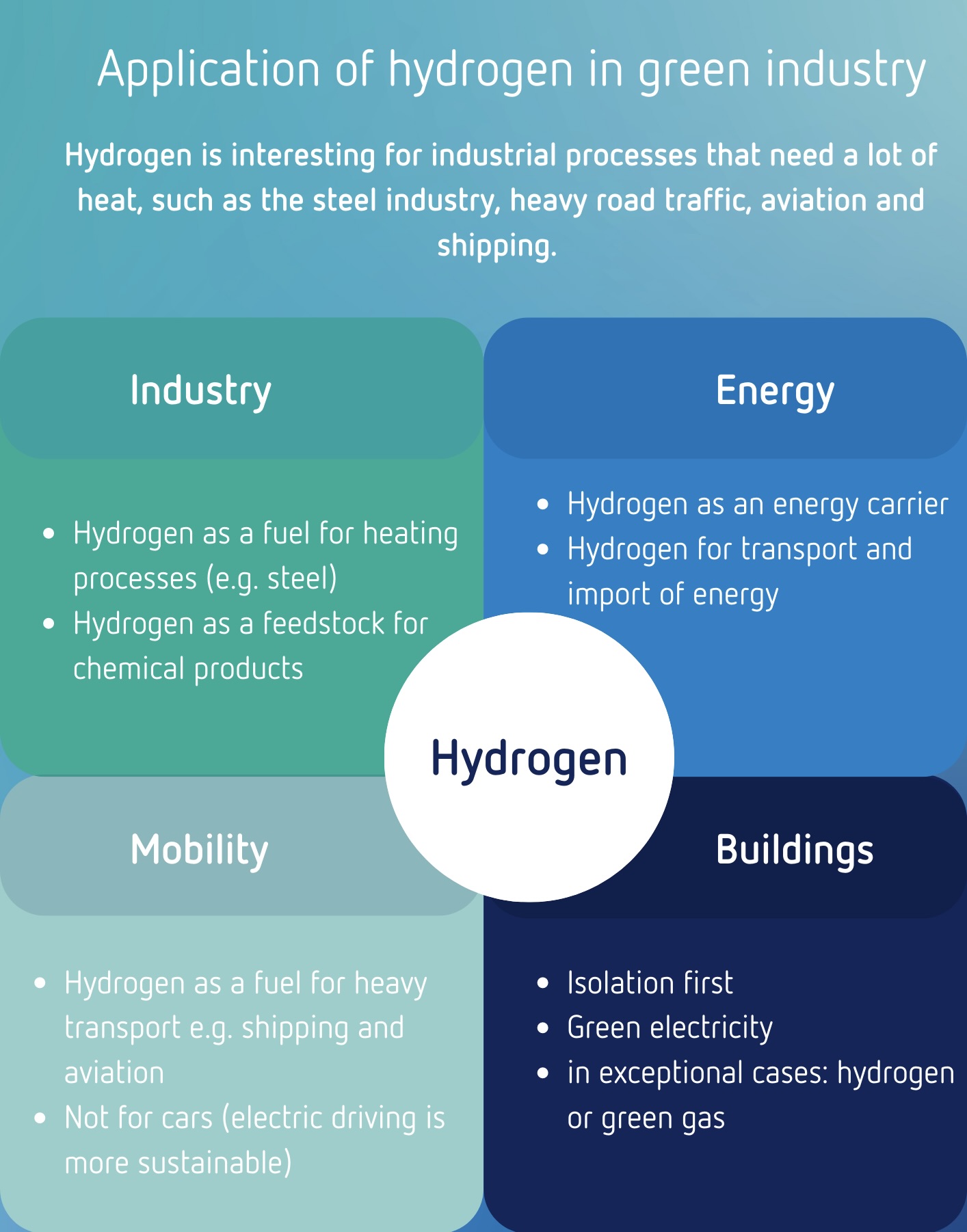

3. Smart application of hydrogen in the industry

At ISPT, we focus on the development of green hydrogen for industrial applications, which serves as a crucial component within a large-scale sustainable energy framework. This form of hydrogen, produced through water electrolysis, serves as a valuable energy carrier, facilitating the storage of renewable electricity generated from sources like wind and solar farms.

The current production method, electrolysis, demands substantial energy input and thereby might seem inefficient due to the conversion process. Therefore, we recognize that hydrogen’s potential for vehicles or as a replacement of electricity in households is limited due to this energy-intensive method.

For processes with temperatures > 700°C

However, for industrial applications, we’re convinced that we only accomplish the energy transition when embracing green hydrogen. The Netherlands seeks sustainable alternatives to replace grey hydrogen and fossil fuels in our industries, especially for processes demanding temperatures surpassing 700°C.

Despite the higher cost of green hydrogen, it is erroneous to assume it can’t compete with grey hydrogen. Adapting to change is crucial for companies, as the consequences of inaction will prove more costly in the near future.

At the moment the Netherlands is well-prepared to start the hydrogen economy, and many companies already have the blueprint, financial picture, and permits ready for their first green hydrogen plants. However, the lack of certainty, such as a clear roadmap and subsidy options, is currently missing. To break this stalemate, parties need to start thinking much more about a crisis, and the government needs to provide clarity on the how, what, where, and when. The responsibility does not lie solely with the government; pioneers in the business world who build hydrogen plants and install the hydrogen backbone can also help to further accelerate the hydrogen economy.

Smart applications for hydrogen in different industries summed up

In the long run, hydrogen will become the energy carrier of the sustainable economy. And the way to get there is mainly through the industry.

Green hydrogen offers a means to:

- Buffer the fluctuations in sustainable electricity production and thereby to create a robust energy system;

- Make sustainable energy available to industries and transport sectors that cannot be powered electrically;

- As a fuel for heavy transport;

- Storage and transportation.

4. Challenges of (green) hydrogen

To achieve the 2030 and 2050 targets of the Paris Climate Agreement, a radical transformation of our energy- and raw materials systems is necessary. Hydrogen has the potential to overcome several sustainability challenges faced by today’s industry.

However, in order to use hydrogen as a sustainable alternative, it must be produced by green electricity and on a large scale by 2030. At the moment, there are still several challenges and there is a need for further research to make green hydrogen a viable and affordable alternative to fossil fuels at scale:

- Firstly, to generate green hydrogen, the availability of renewable energy is crucial. At the moment, only 1% of all hydrogen is being produced using green methods. Therefore it’s crucial to prioritize the production of green electricity at a large scale. This presents challenges, such as the ability of our electricity grid to handle the increase in sustainable energy production.

- Secondly, in the current state, the production of green hydrogen is more expensive than that of natural gas or fossil fuels. This is due to the cost of the renewable energy sources used to produce the hydrogen, as well as the cost of the technology needed to produce and store hydrogen at scale. This proposes some technical challenges associated with scaling up the production of green hydrogen, including the need for improved energy storage solutions and the development of a hydrogen infrastructure to support its distribution and use.

5. How to produce green hydrogen on large (industrial) scale?

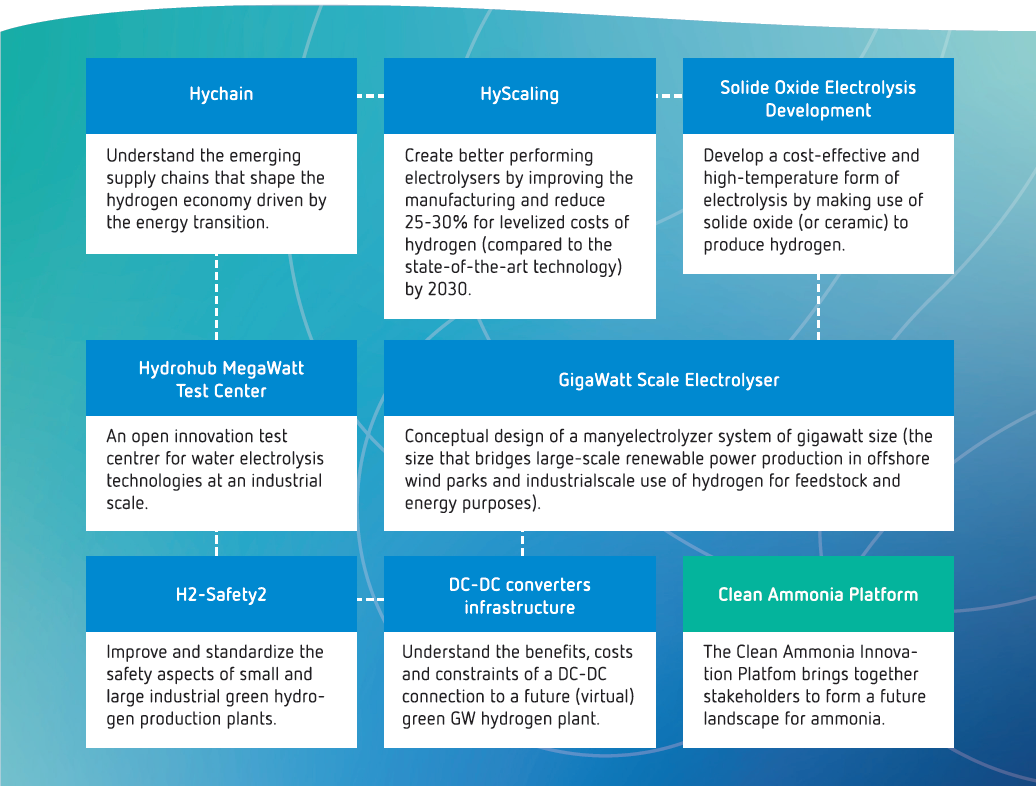

Our program on hydrogen – called Hydrohub Innovation – covers several projects and technological developments in hydrogen, among which a project to produce green hydrogen on a large industrial scale.

Hydrogen vs other energy carriers

The foremost advantage of green hydrogen is that unlike most fuels, hydrogen does not produce greenhouse gas carbon dioxide (CO2) when it is burned. Instead, it yields water. This implies that burning hydrogen fuel has no impact on climate change. The remarkable versatility of hydrogen fuel opens up numerous opportunities to replace fossil fuels across various sectors of our economy.

However, the production of (green) hydrogen through electrolysis demands a considerable amount of energy. In order to produce hydrogen you need electricity, so you use energy of one kind to produce the other kind. That’s not always efficient. Therefore, hyrogen proves less appealing for cars, as electric vehicles are already a viable and efficient option. Similarly, for heating built-up areas, electricity or connection to heat networks suffices, making hydrogen less suitable in these cases.

Therefore, hydrogen’s true potential lies in industrial applications that necessitate extreme heat levels, surpassing what electricity can provide. Industries like steel manufacturing, heavy road traffic, aviation, and shipping demand temperatures reaching 1,200 degrees, which exceed the capacity of electricity’s heating capabilities (up to 400 degrees). In such scenarios, hydrogen emerges as an optimal solution due to its ability to generate the required high temperatures effectively.

Green hydrogen production

As previously mentioned, the production of hydrogen still requires sophisticated methods. While hydrogen is a well-known substance, little options are available for the production of green hydrogen at scale.

Methods for green hydrogen production

Today, the two most prevailing methods of hydrogen production involve steam-methane reforming and electrolysis, where water is split using electricity. At ISPT, our research focuses on accelerating the hydrogen economy through electrolysis. For this process, the two main technologies for water electrolysis are PEM and AWE. In both technologies, water is split into hydrogen and oxygen in an electrolyser – also known as stack. The hydrogen is separated from the oxygen by a membrane.

At the moment, industrial electrolysis of water exist in the Dutch industrial regions of Rotterdam, the North Sea Canal area, Geleen (Chemelot), Zeeland (North Sea Port) and the northern Netherlands. This information follows from the first study results of the Hydrohub GigaWatt Scale Electrolyser project.

Electrolysis: Producing hydrogen from water

To realize the full benefits of hydrogen, the importance of green electricity cannot be emphasized enough. Green electricity, generated from renewable sources like solar and wind, ensures that the production of hydrogen remains eco-friendly and sustainable. By coupling hydrogen production with green electricity, we can minimize carbon emissions and contribute to a cleaner and more sustainable industrial landscape. As we continue to explore ways to decarbonize our industries, hydrogen emerges as a crucial element for a greener and more sustainable future.

Applications of green Hydrogen

1) Applications in the consumer market

The most known applications of hydrogen in the consumer market is the hydrogen-car. A hydrogen vehicle is a fully electric car (EV) powered by one or multiple electric motors. The difference lies between battery-driven EV’s and Hydrogen Cars is in the way energy is stored and converted. In a Battery Electric Vehicle (BEV), energy is stored in the form of electricity within a battery pack. A hydrogen car derives its energy from hydrogen. This energy is not obtained through combustion but rather through a chemical reaction that releases electricity. One advantage of a hydrogen vehicle is that you can refuel it within a few minutes, just like a gasoline or diesel car. However, creating hydrogen requires much more energy than what is released when the hydrogen in the car is converted back into electricity. To cover the same distance with a hydrogen car as with a battery electric vehicle (BEV), you ultimately need a lot more electricity. That’s why we believe hydrogen for cars is not as appealing, as electric driving is more efficient.

2) Industrial appplication

The energy transition cannot be done without green hydrogen. The industrial sector frequently uses grey hydrogen (as an energy carrier and as a raw material) and other fossil fuels. In many cases, green hydrogen is the best sustainable alternative.

Although the price of green hydrogen is high, it is a misconception that it cannot compete with grey hydrogen. Companies have to change, and those who do not will pay a much higher price in the near future. The Netherlands is well-prepared to start the hydrogen economy, and many companies already have the blueprint, financial picture, and permits ready for their first green hydrogen plants. However, the lack of certainty, such as a clear roadmap and subsidy options, is currently missing. To break this stalemate, parties need to start thinking much more about a crisis, and the government needs to provide clarity on the how, what, where, and when. The responsibility does not lie solely with the government; pioneers in the business world who build hydrogen plants and install the hydrogen backbone can also help tremendously.

The current state

The hydrogen market is currently shifting from ‘idea’ towards realization. The Netherlands has set a target in its Climate Agreement to reduce 19,4 Mton CO2-uitstoot in 2030 and achieve an electrolysis capacity of 3 to 4 gigawatts (GW) by 2030, while the European goal is 40 to 60 GW by the same year. But planning and setting goals alone will not get us there. Dutch industry does realize that they must take the helm themselves. But how fanatically each steers that ship varies.

The largest existing hydrogen plant currently has a capacity of 10 megawatts (MW). Concrete plans are in place for a green hydrogen plant in the Netherlands: Shell’s Holland Hydrogen I. The oil company made the final investment decision for this in the summer of 2022. The plant will have a capacity of 200 megawatts, producing 60,000 kilograms of renewable hydrogen per day starting in 2025. Cost: 1 billion euros. The pace in the hydrogen chain differs and as a result, plans and investments are running asynchronously. Result: delay and the Netherlands loses its frontrunner position, despite having all the ingredients to become world leader hydrogen.

Blueprint factory: from megawatt to gigawatt

In January 2022, the Institute for Sustainable Process Technology presented an innovative design for a green hydrogen plant with a capacity of 1 GW. The plant will use both alkaline water electrolysis and polymer electrolyte membrane water electrolysis to produce hydrogen. It will start in a Dutch port area by 2030 and run on wind energy from the North Sea, with the ability to operate flexibly depending on wind conditions.

The design also meets grid code and safety, health, and environmental requirements. This advanced plant is part of the Hydrohub Gigawatt Scale Electrolyser project, which aims to develop affordable large-scale hydrogen production based on electrolysis, driving circular and green chains in industry.

Hydrogen in Research and Development (R&D)

At ISPT we cover all current research projects and technological developments in hydrogen in these projects:

The role of hydrogen in the energy transition

By using hydrogen as a fuel source, we can reduce our dependence on finite and often unsustainable resources such as oil and coal. Additionally, as hydrogen is produced from renewable sources, it can also help to improve energy security by reducing dependence on foreign energy sources. Therefore, moving towards a hydrogen economy can provide a multitude of benefits for society as a whole. Firstly, hydrogen is a clean and renewable energy source, which has the potential to significantly reduce greenhouse gas emissions and help combat climate change. As countries work towards achieving their emissions reduction targets, hydrogen can play a critical role in decarbonizing sectors such as transportation, industry, and power generation.

Another important benefit of moving towards a hydrogen economy is the potential for job creation and economic growth. As the demand for hydrogen increases, new jobs will be created in the areas of research and development, production, and distribution. The growth of the hydrogen economy can also help to revitalize communities that have been impacted by the decline of traditional energy sources.

Moreover, moving towards a hydrogen economy can promote global cooperation and international trade. As countries work together to develop and produce hydrogen technologies, they can share knowledge, expertise, and resources. This collaboration can not only help to accelerate the development of the hydrogen economy but can also help to build stronger diplomatic and economic relationships between nations.

Interesting reads

- 10 years of hydrogen: 3 highlights that involved ISPT

- Creating safety standards with unique consortium of hydrogen parties

- DC-DC: Direct Current connections interesting for more efficient green hydrogen production?

Or follow our LinkedIn-community on hydrogen to stay in the know.

6. Our vision: the next steps

For large-scale hydrogen production, the picture is clear: we need to transition towards more sustainable electricity and cheaper electrolysis,” says Tjeerd Jongsma, Managing Director of ISPT. “We are working on the latter with a consortium of industries, network companies, energy firms, and knowledge institutions.”

Hence, we observe that a comfortable transition to a hydrogen economy is still far from realized. The Dutch industry lacks sufficient guidance. Before investing billions in hydrogen, they require a business case. And for that purpose, the hydrogen supply chain needs to collaborate more closely. We must share knowledge, standardize processes, and mobilize the Dutch chain.

Our role in the energy transition

The industrial sector in the Netherlands plays a crucial role in this energy transition. This is a challenge, but most of all an opportunity.

We belief that the solution lies in connection. Connection between companies, between sectors, and between links in the chain. In this regard, orchestrating entities like ISPT are indispensable to facilitate these connections.

Together with our stakeholders, ISPT is involved in establishing the hydrogen infrastructure that is needed for the energy transition. Given the relevance for both industry and the energy sector, and the scale associated with this, the focus is on large hubs for production at strategic locations, connecting and integrating the process industry with the energy system of the future.

More interesting reads and podcasts

- Webinar: deep dive into the technological hydrogen developments

- All ISPT public reports and whitepapers on hydrogen (free downloads)

- Who? What? Hydrogen! (by Port of Rotterdam, in Dutch)

- Hydrogen in industry (by Shell)

Contact us

Our consortia are always open for more participants. Please feel free to get in touch, we are happy to answer your questions. Relevant contact details for our hydrogen specialists can be found on the ISPT-project pages.

Or follow our LinkedIn-community of monthly newsletter on hydrogen to stay in the know.