Large-scale green hydrogen production by water electrolysis plays a vital role in achieving the CO2 emission reduction targets. Although hydrogen production has been known in industry for decades, operation and maintenance of water electrolysis for producing hydrogen (and oxygen) intermittently is new. It is therefore necessary to exchange knowledge and experiences on process safety, and to develop safety standards to meet expectations of industry, authorities and society.

The Institute of Sustainable Process Technology (ISPT) in collaboration with consortium partners initiated a new project: H2-Safety2. The aim of this project is to develop minimum safety requirements and recommendations for standardization. What makes this new safety project rather unique is that it brings together parties with completely different roles in the Green Hydrogen supply chain. From original equipment manufacturers (OEM), to owner-operators and the Royal Netherlands Standardization Institute NEN.

Safety awareness for green hydrogen production

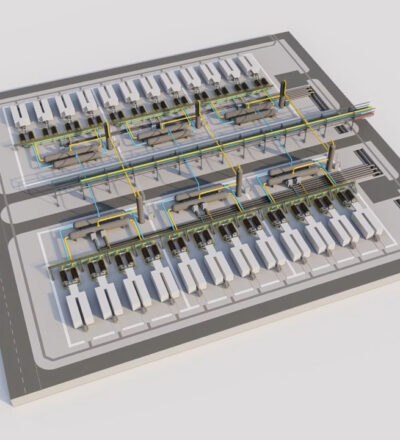

Since society and industry aim to enhance sustainability, the use of renewable energy and green hydrogen production through water electrolysis will grow increasingly in the future. To establish industrial-scale hydrogen plants, a better understanding of safety aspects is crucial, considering intermittency, large-scale installations, and innovative technologies. This new project is the follow-up of the first hydrogen safety project: Green Hydrogen Inherent Safety Practices on large industrial scale. In this second hydrogen safety project we will conduct an in-depth exploration with an expanded team, including the same companies from the previous project.

Accelerate the green hydrogen economy

In this follow-up project, our aim is to enhance risk assessment accuracy to safeguard required (minimum) safety levels. We want to achieve a mutual understanding of process safety aspects between technology providers of electrolyzer systems, EPC contractors, authorities and owners/operators. This understanding is crucial as it forms a prerequisite for the design, implementation, operation, and maintenance of large-scale electrolysis systems for green hydrogen production. In this way we can enable implementation of the energy transition challenges and accelerate the green hydrogen economy.

Developing safe water electrolysis together

ISPT is the overall coordinator and will execute the project with consortium partners Ørsted, Yara, HyCC, Shell, VoltH2, Green Hydrogen Systems, John Cockerill, PlugPower, Royal HaskoningDHV and TNO. NEN participates for standardisation and establishes connections with international bodies and other H2-safety projects. Safety Delta Nederland is supporting this project.

Acknowledgement

This project is co-funded by TKI-E&I with the supplementary grant 'TKI- Toeslag' for Topconsortia for Knowledge and Innovation (TKI’s) of the Ministry of Economic Affairs and Climate Policy.