Green hydrogen is a crucial element in the large scale sustainable energy system of the future. Huge amounts of hydrogen are needed to buffer the fluctuations in electricity production and create a robust energy system. It’s also crucial for industries and transport sectors that cannot be powered electrically.

Hydrogen can be used as energy storage, energy carrier, and feedstock. As an energy carrier, it enables the storage of renewable electricity produced by wind farms and solar plants. It also offers a sustainable alternative for grey hydrogen used by the chemical industry as a feedstock for the production of chemicals. Green hydrogen is one of the key puzzle pieces of the energy transition.

Green hydrogen is crucial for industries and transport that cannot be powered electrically

ISPT works on projects that develop new hydrogen production technologies, scale up existing technologies, and develop the supply chain. Our mission is to ensure progress towards electrolysis-based production of sustainable, low cost, and safe hydrogen at scale as a driver for circular industrial chains

Producing green hydrogen for the Dutch industry

Our green hydrogen projects

The Hydrohub Innovation Platform consists of a continuous base of projects. Within our projects we ensure the entire value chain is represented. We focus on a wide variety of topics, such as safety, technology improvement, upscaling, and innovation. All have the aim to contribute to our mission. Scroll down for an overview of our hydrogen projects.

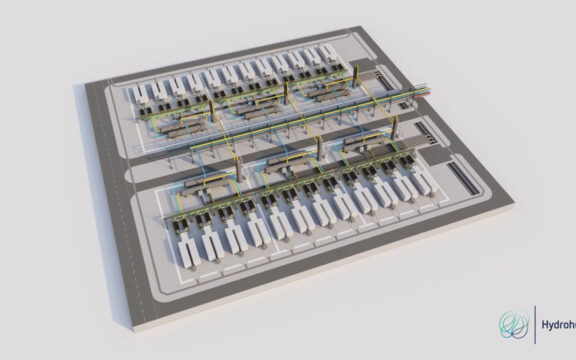

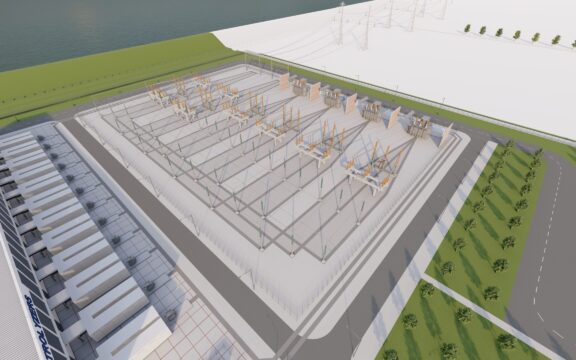

Design of a 1GW green hydrogen plant

In one of our projects we published an advanced design of a 1 gigawatt green-hydrogen plant. It puts us one important step further towards a Dutch hydrogen economy.

Cooperation with partners

ISPT makes every effort to create a trust-based environment, connecting the parties involved and facilitating their sharing of expertise and know-how in joint projects.

We connect the Dutch manufacturing industry, the end users, academic partners to bring innovations rapidly from idea to market. In total, over 90 parties are connected to the Hydrohub Innovation Platform.

Any questions or enquiries?

The Hydrohub Innovation Platform is open for more participants. Please feel free to contact us if you have any questions.