ENCORE – nExt geNeration COmpRession hEat pump

This project demonstrates the enhancement of compression heat pump performance by using a pilot scale test unit.

Completed

CIRCPET – Circular PET trays for perishable food applications

PET trays are currently difficult to recycle. How can we create a fully circular PET tray solution that meets market demands while minimizing environmental impact?

Completed

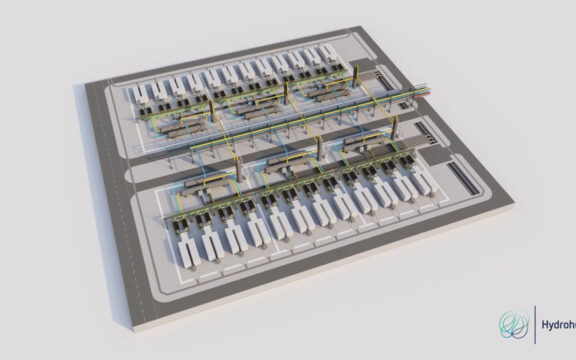

H2-Safety2 – Safety Standardisation of Green Hydrogen Electrolyser Systems

This hydrogen safety project aimed to develop recommendations for standardisation, meeting process safety requirements for large scale water electrolysis. This is an important step to enable a safe, integrated hydrogen-based...

ELSA – Electrically Switchable Affinity Separation Processes

Exploring the advantages of Electrically Switchable Adsorption (ELSA) membranes in the industrial separation process.

MPPS – Multipurpose Plastic Sorting

This project focuses on radically innovating the way we address mechanical sorting of plastic waste.

Completed

Biorefinery Program

Biorefinery enables the production of healthy ingredients and the recovery of valuable components (i.e. proteins) out of process streams.

Completed

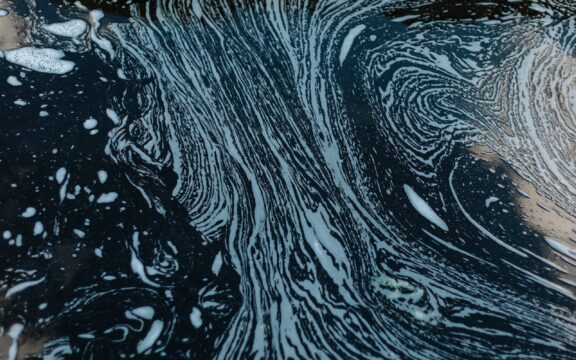

COLFILM – Collapsing Films in Emulsions

In this project computer simulations are used to reveal the impact of a crucial underlying phenomenon: little waves on the surface of droplets that can suddenly grow and thus accelerate...

Completed

Steam and condensate quality

This project focuses on requiering better insights into the distribution and behaviour of conditioning chemicals that is used in their steam-water cycles and condensate polishing. Process industries strive for more...

Completed

FreezeCon – Freeze Concentration

Saving energy, improving product quality with freeze concentration as economically feasible bulk dewatering technology. Background Several technologies are available for liquid concentration in the food industry, the most common being...

Odysseus

Goal of this project is to develop a library of complementary techniques for concentrating brines beyond reverse osmosis.

New

Ammonia to Power

The Ammonia to Power project explores the techno-economic potential of ammonia powered electricity generation.

SUNSOLr: Electrification of Chemical Conversions

The SUNSOLr project is dedicated to developing technologies for the direct electrification of chemical conversions, focusing on CO2 and H2O/H2 to produce chemicals like CO, CH4, olefins, and methanol.

Completed

IMPROVISE – Improved process operation via rigorous simulation models

Improved daily operations of important chemical processes in the Dutch chemical industry through operation technology based on detailed physical models. Incentive Being able to anticipate what a chemical process is...

Completed

WeCare – We Create Awareness & Reduce Energy

The WeCARE project demonstrated the possibilities of Artificial Intelligence technology of EnergQ at a selected number of end users. EnerGQ’s self-learning energy management technology unveiled the excessive energy consumption and with that...

Completed

LEMPLAR – Losses & Emissions in Plastic Recycling

The plastic recycling process today has losses and emissions, such as microplastics, inks and incorrectly sorted plastics. This prevents us of closing the plastic cycle.

Completed

Novel Process Routes – Reduction of energy use by novel process routes for food (ProFo)

Several partners are working towards a 50% reduction of energy use developing novel process routes in food processing.

Fingerprint 2 Footprint

Fingerprint 2 Footprint translates chemical fingerprint measurements inside and near chemical processes to reduce environmental footprints, while retaining or improving process economy and consistency.

Completed

Probiotics – Low energy living bacterial food formulations

Research towards a novel and generic strategy for probiotics in low energy living bacterial food formulations

Completed

GreenWedge

The GreenWedge project helps SMEs actively market their sustainable technology.

ReValue – Recovery of Valuable minerals with hybrid ceramic membrane crystallization

The ReValue project explores the potential of membrane crystallization, a promising technology to recover valuable compounds from aqueous streams.

Completed

IoF – Internet of Food

The Internet of Food (IoF) project defines the sharing of data and models in order to improve sensing systems in food production.

ReCYCLE – Electrical bike with durable circular plastic parts

ReCYCLE is a cutting-edge project that combines electric bikes with durable circular plastic parts, pushing the boundaries of innovation in sustainability.

The Heat Is On

The Heat is On aims to make processes for dewatering, drying and heat integration more efficient.

LESSON – Oil free compressor for ammonia based high temperature heat pumps

Wet compression allows for close to isothermal conditions during compression resulting in higher compression isentropic efficiencies. It further prevents operation in the superheating zone of the working fluids of heat...