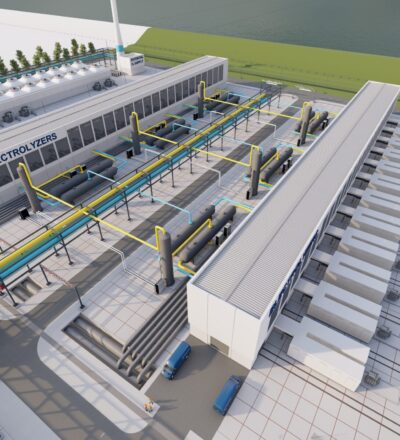

To meet the CO2 emission reduction goals from the Climate Agreement, we need large-scale production of green hydrogen through water electrolysis. In the process industry safety aspects of fossil-based hydrogen production is well-known, but there is limited experience with large-scale water electrolysis.

In short:

- The starting point for this project was the limited experience with large-scale water electrolysis

- This project tackled the question of how industry, authorities and society can aim for zero incidents with large-scale water electrolisis

- The project resulted in a uniform safety approach and increased awareness of safety for industrial scale electrolysis plants

The knowledge-gap

Today electrolyser suppliers, operators and owners have limited operating experience with safety aspects related to large scale water electrolysis installations. While these large-scale installations are becoming reality soon, only limited data on the safety aspects related these novel large scale installations exists. Meaning that safeguarding process safety in the design, implementation and operation phases is a complex task. A lack of a common understanding may lead to delays in process design, but moreover, it can potentially lead to an underestimation of the risks involved.

Therefore, the Institute for Sustainable Process Technology and partners wished to further advance all related safety aspects and develop a uniform safety approach for large-scale water electrolysis plants. The ‘Green Hydrogen Inherent Safety Practices on Large Industrial Scale’ project addressed this need with a one-year project. The results of this project are discussed in the final report aiming at a more uniform approach for risk assessment of large-scale green hydrogen production.

What is the potential risk?

In this project, the focus was on deeping the understanding of the potential risks of explosions due to mixtures of hydrogen and oxygen in electrolysis equipment and loss of containment inside a building. One of the questions was, for example, how to objectively assess scenarios with exceptionally low probability and high potential consequences (black swans) and how to determine cost-effective safety measures to address these. The development of consistent assessment methods covered failure frequencies and consequences, including data on delayed ignition and detonation, leading to corresponding safeguarding and appropriate safety distances.

Project results

Through outcomes of this one-year research project, best practices for inherent safe design and guidance for hazard assessment and risk mitigation were compiled. As project partners emphasized the need for scenario-based thinking, the project team developed joint safety practices and guidelines based on credible scenarios for large-scale plants.

The results are gathered in the ‘Safety Aspects of Green Hydrogen Production on Industrial Scale‘ report. This report proposes a consistent risk assessment methodology for large-scale green hydrogen plants.

Next steps

Based on on the results of the report, ISPT and partners initiated a two-year follow-up project Safety Standardisation of Green Hydrogen Electrolyser Systems. This project aims to develop minimum safety requirements and recommendations for standardisation and is a cooperation of the existing consortium, selected electrolyser suppliers and the Netherlands Standardization Institute (NEN).

This project was initiated with our consortium partners HyCC, Ørsted, Shell, Yara, DNV, Royal HaskoningDHV, and TNO.

Interesting reads on Hydrogen

- Safety first: new report sheds light on industrial-scale green hydrogen safety

- Safety Standardisation of Green Hydrogen Electrolyser Systems

- Launch of the Green Ammonia Innovation Platform

Our join our Hydrogen LinkedIn-community.

You might also be interested in

Acknowledgement & partners

This project is co-funded by TKI-E&I with the supplementary grant 'TKI- Toeslag' for Topconsortia for Knowledge and Innovation (TKI’s) of the Ministry of Economic Affairs and Climate Policy.