Nationale Technologiestrategie (NTS) Actieagenda Procestechnologie

De Actieagenda Procestechnologie richt zich op het versterken van het Nederlandse verdienvermogen, de strategische relevantie en het realiseren van de klimaat- en milieudoelstellingen door innovatie in procestechnologie.

Material property changes during electro-hydrodynamic drying (EHD): a closer look into the falling rate period

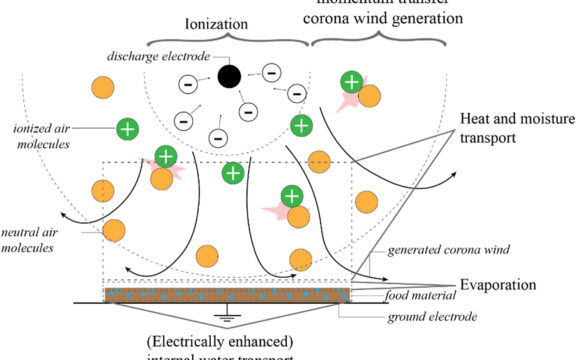

Electrohydrodynamic (EHD) drying offers an alternative to hot air drying thanks to its lower energy use and lower operating temperatures. EHD drying benefits from enhanced convection induced by the corona...

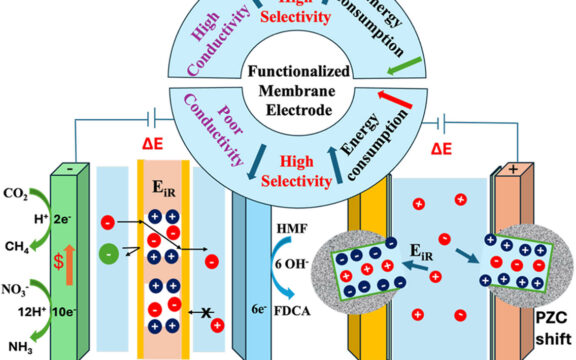

Critical evaluation of factors influencing the specific energy consumption of electrically driven membrane separation technologies

Electrodialysis (ED) and capacitive deionization (CDI) are electrically driven separation technologies with strong potential to advance renewable and sustainable goals, as they can be powered by renewable electricity, while enabling...

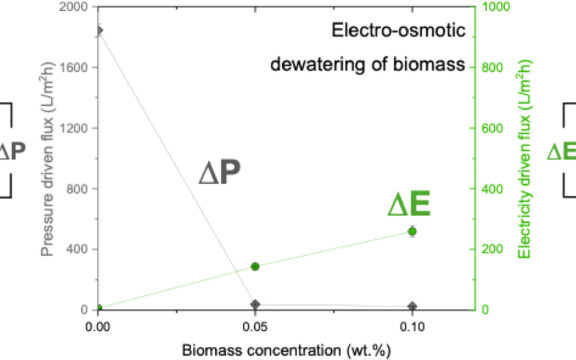

Electro-osmotic membrane dewatering of biomass: influence of membrane morphology, surface charge and process parameters

Formation of the EDL at a negatively charged surface (red) and its electromigration under an applied electric field resulting in the slip of adjacent water layers, known as electro-osmotic flow.

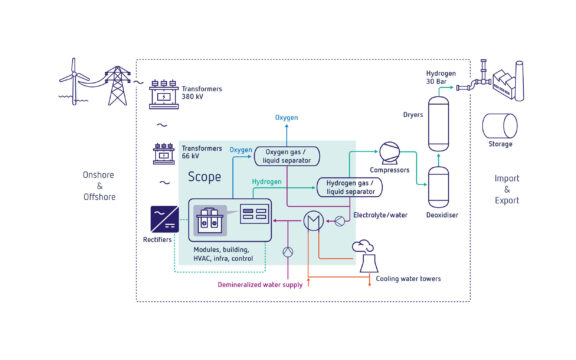

Enabling Safe Green Hydrogen Production – Needs for Standardisation

This report aims to map the needs relevant to safety standardisation during the multiple project phases of the design and operation of green hydrogen production facilities and the related permitting...

Design and Safety Aspects for large-scale Clean Ammonia Pipelines

This report explores the design, technical, and safety considerations of a 550 km ammonia pipeline.

Webinar: Ensuring Safety in Green Hydrogen

This webinar features insights from the H2-Safety2 project, in which key industry players are collaborating to develop safety guidelines that ensure safe design, operation, and maintenance of electrolysis systems.

Enabling Safe Green Hydrogen Production on Industrial Scale – A Process Safety Study

This report dives deeper into the technical safety risks, scenarios and design implications for electrolysis using Alkaline Water Electrolysis (AWE) and Proton Exchange Membrane (PEM) technologies.

A multi-scale analysis on electrohydrodynamic drying technology forbio-based & food products

Background Electrohydrodynamic (EHD) drying relies on the generation of a corona wind that is created with ahigh electric potential between an emitter and a ground electrode. The impinging corona wind...

Anomalous enhanced swelling of charged copolymer gels

Highlights Abstract Copolymer gels are a class of hydrogels that possess at least two different monomers within the same polymer chain. A common method for synthesizing copolymer gels is the...

Carbon feedstock transition of the petrochemical industry under spatial limitations

This report provides an analysis of the transition pathways for the Harbour Industrial Cluster (HIC) in Rotterdam, accounting for the effect of limited space and exploring the effect of global...

Publiekssamenvatting – Koolstof grondstoftransitie van de petrochemische industrie binnen beperkte ruimte

Download hier de publiekssamenvatting van 'Een scenariostudie van de transitie van het Rotterdamse Haven Industrieel Cluster'

Public Summary – Carbon feedstock transition of the petrochemical industry under spatial limitations

Download the Public Summary of the scenario study.

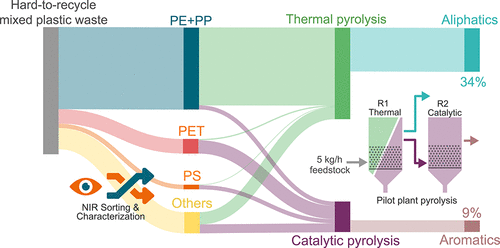

Full Utilization of Hard-to-Recycle Mixed Plastic Waste by Conversion toward Pyrolysis Oil and BTX Aromatics on a Pilot Scale

This study investigates the technological feasibility of recycling mixed plastic waste streams into chemical building blocks on a pilot scale.

Pyrolysis of Dutch mixed plastic waste: Lifecycle GHG emissions and carbon recovery efficiency assessment

This study explored the potential of pyrolysis as a novel approach to managing plastic waste and achieving plastic circularity in the Netherlands.

From mist to matter: Steering particle structure development during pilot-scale spray drying

Spray drying is a widely applied method for producing shelf-life stable powders such as food ingredients. During drying, a liquid feed is atomized into small droplets and exposed to hot...

Pyrolysis of Polyolefin-Enriched Mixed Plastic Waste Streams: Effects of Pretreatments and Presence of Hydrogen during Pyrolysis

Pyrolysis is considered a promising method for the chemical recycling of mixed plastic waste streams, yet systematic experimental evaluations of these mixed streams remain limited. Herein, the pyrolysis of a...

Pyrolysis of polyethylene: chemical kinetics, mass transfer, and reflux system

This paper focusses on the interplay between reaction kinetics and mass transfer rates in pyrolysis of polyethylene (PE), and the effect of adding a reflux system to the semibatch reactor...

Single droplet drying to steer particle agglomeration during spray drying

Large scale food processes allow mass-production of well-preservable food materials, such as powders produced by spray drying. However, the food industry is consuming a lot of energy, and drying is...

Losses and emissions in polypropylene recycling from household packaging waste

In this study the LEMPLAR consortium replicated a typical high-quality post-consumer polypropylene (PP) recycling process to investigate its losses and emissions and study potential improvements.

White paper: BECC(U)S in de verkenning van toekomstige energiesystemen

In dit white paper lees je waarom De Tekenkamer van de Industrie stelt dat BECC(U)S als relevante optie voor CO₂-vrij regelbaar opwekvermogen niet bij voorbaat mag worden uitgesloten.

How Explainable AI can accelerate the digital transformation of the industry

This white paper explores how XAI can revolutionise data collection, analytics, and visualisation, making AI more accessible and trustworthy.

Mechanical Recycling of PET Multi-Layer Post-Consumer Packaging: Effects of Impurity Content

The recycling of PET trays is highly challenging. The aim of this paper was to investigate the issues related to the mechanical recycling process and, the correlation between feedstock composition...

HyScaling – Public end report

The specific objective of HyScaling was to achieve 25-30% cost reduction for levelized cost of hydrogen compared to the state-of-the-art at the beginning of the project by bringing the HyScaling...