In ReCYCLE we focused on creating durable circular plastic parts for the use of electric bikes, pushing the boundaries of innovation in sustainable engineering thermoplastics.

In short:

- Demonstrated that key e‑bike parts can be made from high‑quality recycled plastics.

- Developed a toolbox for circular design, including guidelines for disassembly and material selection.

- Created a decay model to predict long‑term performance of recycled thermoplastics Acrylonitrile Butadiene Styrene (ABS) and polycarbonate (PC).

The challenge: recycling and repurposing of materials

As demand for electric bikes continues to grow, so does the need to ensure their production aligns with the European Union’s and the Dutch government’s sustainability goals. The aim is to achieve a circular economy for plastics by 2030 and 2050, but current practices fall short of this. Specifically, we need to change our approach to engineering thermoplastics and create a closed loop that allows for the recycling and repurposing of materials, thereby reducing their carbon footprint.

ReCYCLE: creating circular electric bike parts

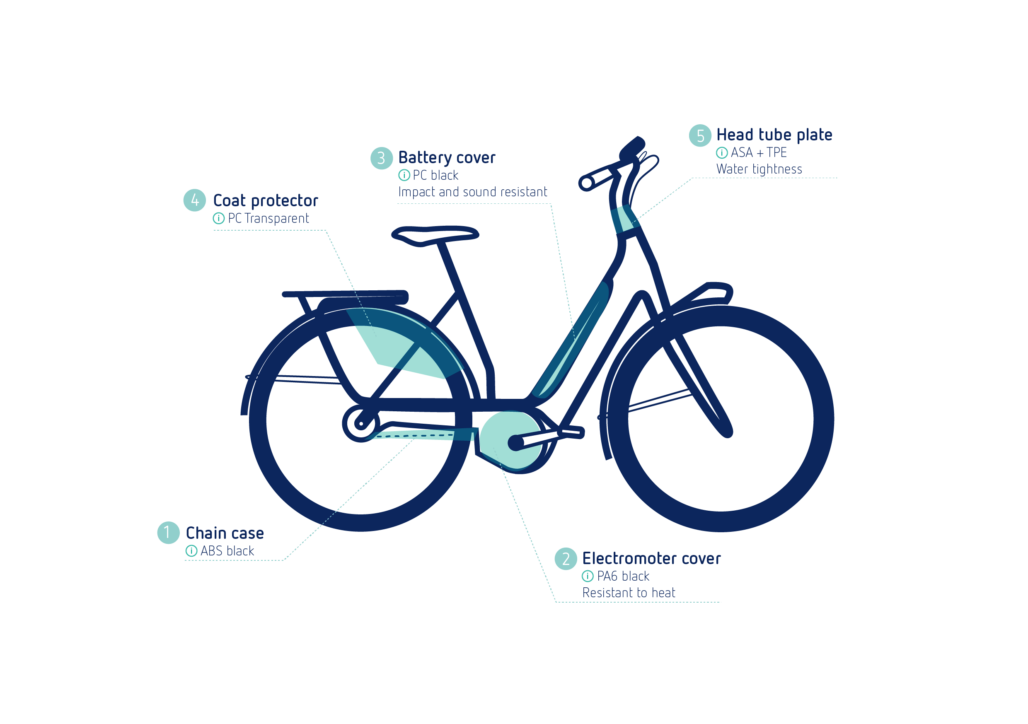

The project focused on five electric bike parts:

- Chain case

- Electromotor cover

- Battery cover

- Coat protector

- Head tube plate

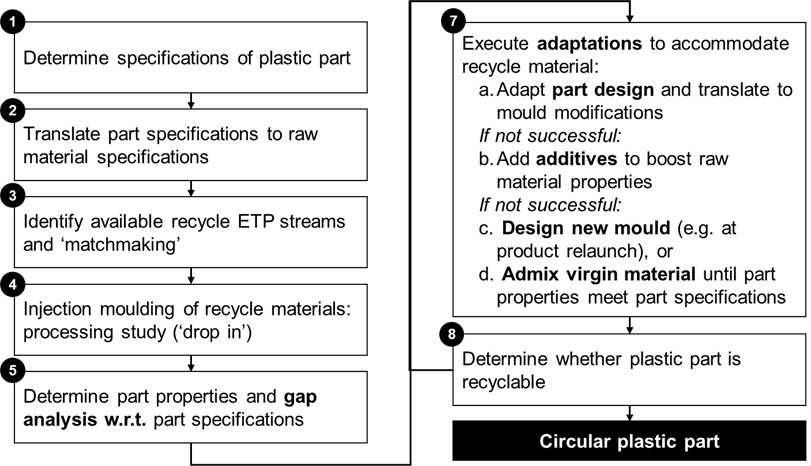

For each bike part, a staged circularity approach was adopted. This started with the simplest solution of ‘dropping in’ 100% recyclate into the part and ended with the most complex and costly solution of completely redesigning the part and creating a new injection mould. After each stage, it was assessed whether the part met the required specifications. If so, the subsequent stages were not executed. If not, the next stages were carried out until success was achieved. Activities included:

- Defining part requirements.

- Translating these into R‑ETP material specifications.

- Running injection moulding trials with R-ETP.

- Improving the recycled materials in activity.

- Optimizing part design to accommodate R-ETP.

- Complete part redesign and a new mould

- Testing to determine how many lifecycles the parts can bear and the development of a decay model.

- Determining life‑cycle impact of the R-ETP solutions and calculating carbon footprints.

Results

1. Validated circular bike parts using R‑ETP

Full sets of technical requirements were established and validated using prototype parts. These include mechanical performance, aesthetic quality, assembly properties, weathering resistance, chemical resistance, and CO₂‑performance.

2. Clear overview of R‑ETP availability

The project mapped the availability of recycled engineering plastics in the Netherlands and the EU. Findings include:

- PCR‑ABS is widely available.

- PCR‑PA6, PCR‑TPE, and PCR‑PC exist but remain limited.

- Some materials, such as PCR‑ASA, are not available.

- Most recyclates must be sourced outside the Netherlands.

Because availability drives scalability, additional polymers were tested to widen application potential.

3. Circular material choices for each bike part

The project achieved successful circular versions of all five parts:

| Part | Virgin material | Circular R‑ETP solution |

|---|---|---|

| Chain case | ABS black | PCR‑ABS black |

| Electromotor cover | PA6 black | PCR‑ABS black |

| Battery cover | PC black | High‑impact PCR‑ABS |

| Coat protector | PC transparent | PCR‑PET transparent or PCR‑PC |

| Head tube plate | ASA + TPE | 2K: PCR‑ABS + PCR‑TPE / 1K: PCR‑ABS black + silver PCR‑ABS |

Notably, using PCR‑ABS for both the chain case and motor cover enables disposal as a mono‑stream, simplifying recycling.

4. Toolbox for circular engineering plastics

The project created a practical design toolbox that includes:

- Material selection guidance

- Design-for-circularity and design-for-disassembly rules

- Lessons learned from material trials

- A process-flow diagram for developing circular components

5. Decay model for recycled ABS and PC

A new test protocol simulated realistic mechanical recycling combined with accelerated aging.

Key findings:

- ABS and PC show predictable declines in impact strength after one recycling step.

- Other mechanical properties remain largely stable.

- ABS degrades significantly less than PC.

- Aging behaviour of post-consumer recycled materials closely mirrors that of virgin materials.

- Without downgrading, maintaining performance requires impact modification and colour correction.

6. Multiple possible recycling loops

If downgrading is allowed, the materials can be reused many times:

- ABS: 5–14 cycles

- PC: 2–4 cycles

7. Significant CO₂‑reduction based on LCA

Switching to R‑ETP leads to strong climate benefits:

- –68% CO₂‑eq for the battery case

- –55% CO₂‑eq for the motor cover

- –55% CO₂‑eq for the coat protector

Reductions in acidification and particulate matter were also achieved, except where long transport distances increased particulate emissions — underlining the importance of local recycling capacity.

This is a project of the Circular Plastics Initiative, co-founded by ISPT and DPI.

You might also be interested in

Articles / Publications

Acknowledgement & partners

This project is co-funded with subsidy from the Topsector Energy by the Ministry of Economic Affairs and Climate Policy.