Plastic is everywhere – and for good reason. It’s lightweight, durable, and often the most efficient material available. However, the downsides of our current plastic usage ask for change. With only a fraction of plastic packaging currently recycled into high-quality material, the need for a smarter, more integrated system has never been greater. That’s exactly what the InReP project set out to develop – and did.

In short:

- Developed new integrated recycling pathways for polyolefins and PET packaging.

- Demonstrated high-quality, recycled plastics through pilot-scale testing.

- Created the InReP Plastic Recycling Explorer to model future circularity scenarios.

- Offered clear policy recommendations to support innovation and standardization.

About the project: Designing a cascaded recycling system

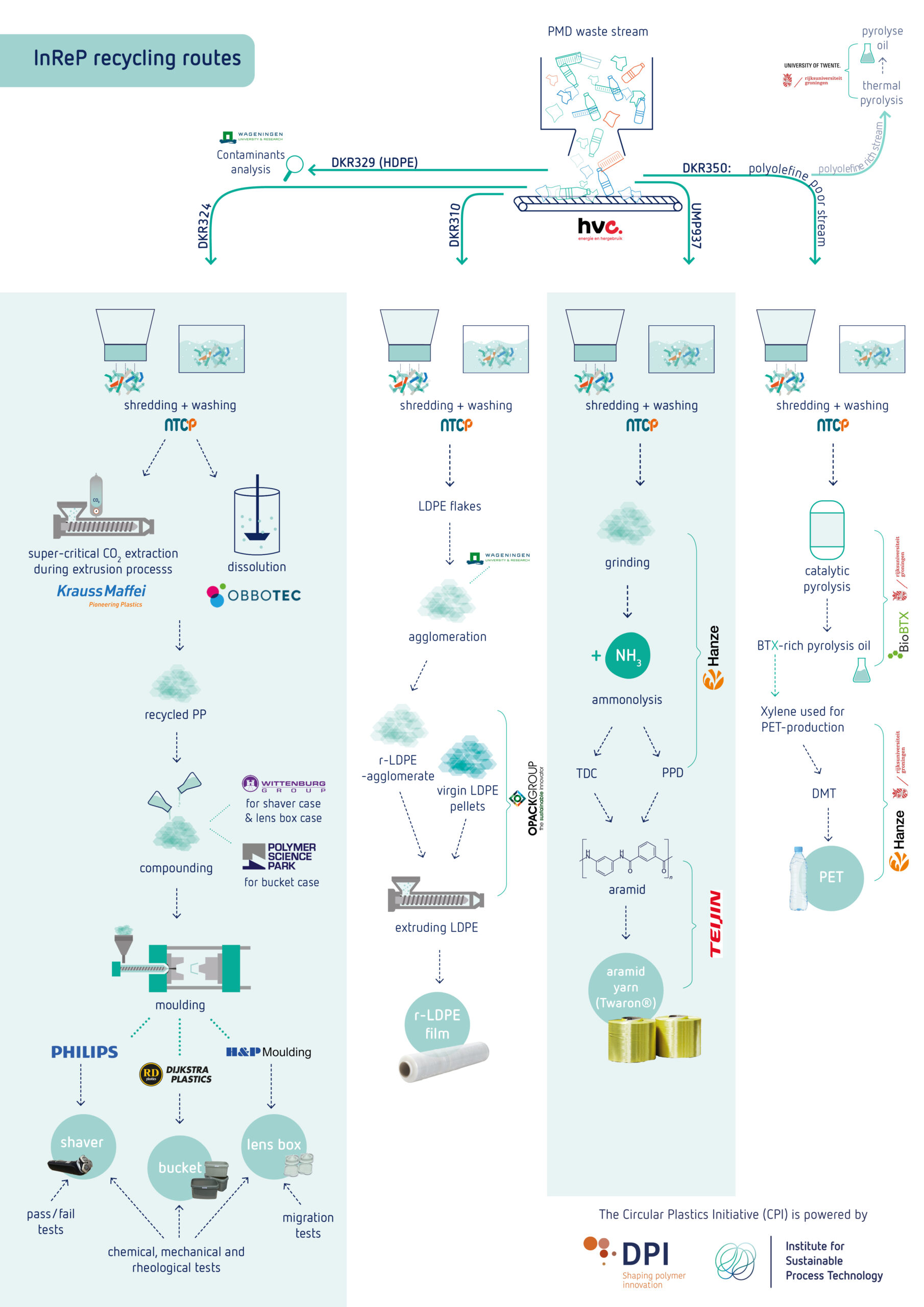

The InReP project united 33 partners to find new ways how to sort, treat, and recycle (packaging) plastic waste in order to deliver recycled plastics with value. Focusing on polyolefins (PE/PP) and PET, the project tackled challenges across the entire recycling chain, from collection and sorting to mechanical and chemical recycling. Different types of post-consumer waste is being used, like LWP (lightweight packaging waste, PMD in Dutch), MSW (municipal waste), PSW (public solid waste), and commercial waste, to identify optimal recycling pathways and to test new technologies.

Results

The InReP project has resulted in many new technological breakthroughs, application options and insights in the system as a whole. This is an achievement the entire consortium has contributed to and is very proud of. The contribution and dedicated involvement of all consortium partners has led to results and insights that can be used for future initiatives to support the transition towards circular plastics.

- Integrated recycling routes were developed that combine optimized sorting with mechanical, chemical and thermochemical recycling, enabling higher‑quality outputs across PE, PP and PET waste streams.

View the InReP recycling routes

- High‑quality recycled PP and PE were successfully produced, including demo products (e.g., shaver, lens box, buckets, LDPE film), supported by new decontamination technologies such as solvent‑based recycling and supercritical CO₂ extraction.

- Chemical recycling pathways were validated, including PET‑tray depolymerisation into pure building blocks for aramid fibres and catalytic pyrolysis routes yielding BTX chemicals for new plastics.

- Detailed analyses revealed how contamination enters and behaves in the plastic lifecycle, providing essential insights for improved design, sorting and recycling performance.

- The InReP Plastic Recycling Explorer visualizes various current and future plastic recycling scenarios using existing and new InReP related data and insights, providing a systems overview of today and the future. The tool showed that cascading recycling technologies greatly improve circularity, but meeting future circularity goals also requires better product design, reduced plastic use and the introduction of renewable plastics. For more information and access to this tool, please contact mateo.gongoratorres@tno.nl.

Policy brief

According to the InReP consortium, there are currently major inconsistencies between the needs of the industry and the limited scope offered by current legislation to enable a true transition to circular plastics. Based on joint research and innovation results, the consortium makes an urgent appeal to European policymakers in this call to action to focus on three key areas:

- Develop an integrated vision, supported by coherent and realistic policies and regulations that stimulate innovation.

- Create a legal framework for the mandatory standardisation of packaging, in order to boost circularity, recyclability and quality.

- Establish a clear policy framework for cascading recycling technologies, to ensure sufficient volumes of high-quality recycled materials.

This is a project of the Circular Plastics Initiative, co-founded by ISPT and DPI.

You might also be interested in

Articles / Publications

Full Utilization of Hard-to-Recycle Mixed Plastic Waste by Conversion toward Pyrolysis Oil and BTX Aromatics on a Pilot Scale

Pyrolysis of Polyolefin-Enriched Mixed Plastic Waste Streams: Effects of Pretreatments and Presence of Hydrogen during Pyrolysis

Pyrolysis of polyethylene: chemical kinetics, mass transfer, and reflux system

Mechanical Recycling of PET Multi-Layer Post-Consumer Packaging: Effects of Impurity Content

Volatile organic contaminants in HDPE milk bottles along the mechanical recycling value chain, revealing origins and contamination pathways

Strategies to enhance the circularity of non-bottle PET packaging waste based on a detailed material characterisation

Scenarios as input to InReP

Acknowledgement & partners

Topsector Energiesubsidie van het Ministerie van Economische Zaken en Klimaat.