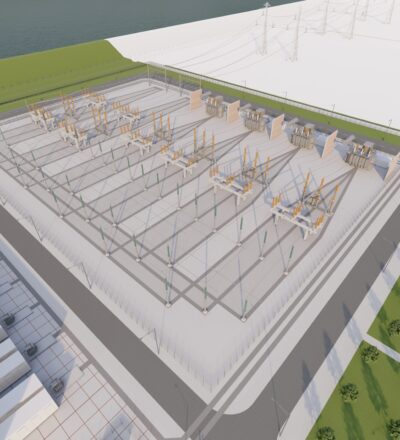

The electrical system plays a vital role in a green hydrogen plant as it converts grid electricity (380 kV, AC) to the needs of the electrolyser stacks (1,200 V, DC). In this project, our aim is to investigate the benefits, costs and constraints of connecting a High-Voltage Direct Current (HVDC)/ Multi-Voltage Direct Current (MVDC) infrastructure to a future (virtual) green GigaWatt hydrogen plant in The Netherlands. This initiative holds the potential for future development and implementation by the end of this decade.

In short:

- Explore DC-DC connections for large-scale green hydrogen plants to address space constraints, reduce investment costs (up to 25%), and mitigate significant electricity losses compared to traditional AC grid connections

- This is a feasibility study focusing on technical and economical evaluation of DC-DC converters

DC-DC connections: a logical choice

The electricity grid and most of the electrical devices use Alternating Current (AC). However, water electrolysis for the production of green hydrogen uses Direct Current (DC). Electrical installations transform voltage from high to medium to low (HV/MV/LV) by means of transformers, and convert alternating current (AC) to direct current (DC) by rectifiers. This electrical-system layout takes up much space of a green hydrogen plant. Furthermore, it can add up to one quarter of the total investment costs and the electricity losses can be significant. It is therefore logical to look at the opportunities and benefits of DC-DC connections for large scale green hydrogen plants as opposed to the regular AC grid connected solutions.

Technical and economical aspects of DC-DC converters

In this project the benefits, costs and constraints of DC-DC converters for large-scale green hydrogen production are assessed in an electrical study. It will also investigate the requirements, enablers and conditions for this technology. This will be done by comparing market available solutions in the next 5-10 years for supply of electricity to onshore/ offshore large-scale electrolysers. These are:

- The conventional AC-DC electrical infrastructure with transformer-rectifiers as per referenced GW plant design

- An electrical infrastructure with a direct connection of converters of the electrolysis process to HVDC and/or MVDC grids

Project results

The consortium consisting of ISPT, Hitachi Energy, Equinor, HyCC, Ørsted, Port of Rotterdam, and Yara, has completed the feasibility study to explore a (hybrid) electrical layout with DC and AC connections. The study focuses on developing optimised power conversion schemes for a gigawatt (GW)-scale water electrolysis plant. The objective is to prepare a conceptual design for a converter topology that enables the integration of this new electrical layout, highlighting both its benefits and limitations.

A new electrical layout with innovative power converters has been selected due to its relatively high maturity level, the suggested higher efficiency, the potential lowest complexity, costs, and footprint. It is recommended that the proposed innovative converters be further investigated to optimise the techno-economic size and feasibility, improve power quality, galvanic isolation and interfaces with the electrolysers.

You might also be interested in

Articles / Publications

Acknowledgement & partners