The Circular Plastics Initiative (CPI) holds the view that the transition of the production of plastics will play a vital role in contributing to a circular economy in the Netherlands. We are convinced that the material transition offers an outstanding opportunity for the Netherlands to assume international leadership in the production of sustainable and circular products. Together with our invaluable partners, we have achieved a lot since we started in 2019. In this article we will give an overview of the path taken and what lies ahead.

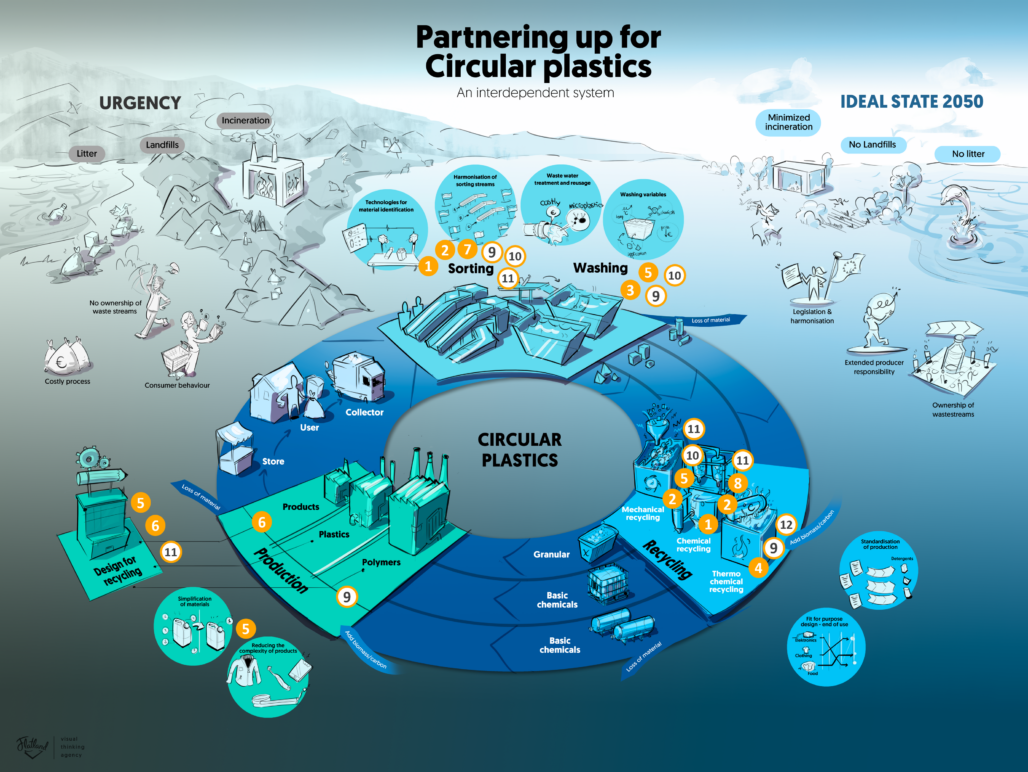

The Circular Plastics Initiative (CPI), an cooperation between the Institute of Sustainable Process Technology (ISPT) and the Dutch Polymer Institute (DPI), focuses on uniting expertise of industry and knowledge institutes. This led to the development of the CPI roadmap.

The roadmap is the central pillar within the CPI to guide the direction of developments and help identify future steps where collaborative action is needed.

All active, finished and submitted projects within CPI

- Towards the improved circularity of polyolefin-based packaging

- InReP – An integrated approach towards the reycling of plastics

- LEmPlaR – Losses and emissions in plastic recycling

- HOPy – Headstart on pyrolysis

- CIRCPET – Circular PET trays for perishable food applications

- ReCYCLE – Electrical bike with durable circular plastic parts

- MPPS – Multipurpose plastics sorting

- Aramazing

- to 12. Recently submitted proposals on a range of topics, including pyrolysis, mechanical recycing and circular textiles

Past progress in circular plastics

Pivotal for the Circular Plastics Inititative (CPI) was the successful finish of the first large consortium project (1) with a focus on different (technological) innovations for mixed plastic waste. Key results were the improved sorting of black plastics, simplified and faster characterization methods, insights into pre-treatment of mixed plastic waste for pyrolysis and gasification, and a better understanding of these recycling pathways through life cycle analysis. Yet, most crucial was that this project has led to a better understanding of the role each partner can play in moving from a linear value chain towards a circular value chain. This is a result of interaction and exchange of information among the consortium partners.

Another important milestone was broadening our activities from recycling of packaging waste to include specialty and engineering types of plastics. For instance, the project ReCYCLE (6) involves the recycling and reuse of plastic materials in a Dutch landmark product: the (electric) bicycle, with elements of mechanical recycling and design for recycling, as well as design from recycling.

Most recently, CPI started with a large-scale initiative, Aramazing (8). This project focuses on the chemical depolymerization of aramid fibers, known for their heat resistance and strength in a variety of endurance products. A key element is collaboration with partners to establish an effective collection system for used textiles and technical products. The project aims to lay the groundwork for scaling up to industrial levels, contributing to the circular and CO2-neutral production of aramids.

The projects mentioned above are just 3 projects from our extended portfolio. At CPI, we are committed to pushing the boundaries of circular plastics innovation even further. We currently have 4 additional proposals currently under consideration, focusing on key areas such as mechanical recycling, pyrolysis, and the development of circular textiles.

Future steps in achieving circular plastics

CPI is continuously seeking to update and further specify the next steps in circular plastics. You are invited to be part of our growing network. This means cross-fertilization of knowledge and value chain development through strategic meetings, the annual Circular Plastic Conference (CPC) and ongoing interactions.

Stay up to date by following our LinkedIn-page and get to know the latest developments, started projects, and the results of our current projects.