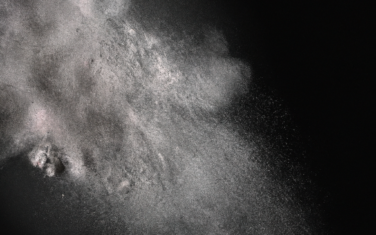

Recognized as energy-intensive operations, drying and dewatering processes constitute approximately 15% of the total energy consumption within the Dutch industrial landscape. Many products require some form of drying during their manufacturing or processing, spanning from paper and chemicals to various food products. However, the industry is currently grappling with a mounting array of energy-related challenges – ranging from escalating costs and volatile energy markets, to sustainability concerns – particularly concerning the removal of water from raw material streams.

To feed the growing world population without placing an untenable burden on our environment, we need to redesign our food industry in a sustainable way, with new process technologies that help us maximize nutritional values and minimize energy consumption, as well as waste in the food chain.

Our vision

Our vision is a future where process technologies are the driving force behind a sustainable food transition, with a particular emphasis on minimizing energy consumption. We strive for the development and implementation of advanced technologies that not only increase the efficiency of food production but also maximize the use of renewable energy sources. Through this focus, we aim to play a leading role in shaping a food system that is not only resilient and ecologically responsible but also energy-efficient, thereby ensuring a sustainable future for generations to come.

Drying is one of the most energy-consuming processes in the process industry

Our mission

Our mission is to develop innovative process technologies that promote the food transition with an explicit focus on optimizing energy consumption. We strive to develop groundbreaking methods that enhance the sustainability of food production, reducing reliance on traditional energy sources and embracing sustainable, energy-efficient alternatives.

Our efforts are aimed at creating a food system that is not only healthier and more environmentally friendly but also significantly consumes less energy.

Challenges we foresee in 2024

More efficient processing

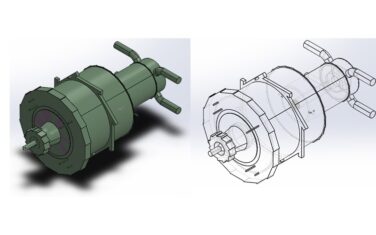

Developing technologies that increase the efficiency of food processing, with a focus on reduced energy usage, minimization of waste streams, and optimization of raw materials. Examples include energy-intensive technologies for dewatering and drying. An additional challenge is processing an increasing stream of plant-based products, which generally require three times more energy than conventional streams, such as dairy.

Digitalization of food processing processes

Implementing advanced digital technologies, such as Artificial Intelligence and Digital Twins, in process control systems that optimize themselves for energy consumption, product quality, and food safety.

Valorization of residual streams

Developing energy-efficient processes that convert residual streams into valuable products. This preserves the energy used upstream in the chain to prepare raw materials for processing. Examples include mild fractionation of residual streams into food ingredients. Another related challenge is reducing fouling and improving cleaning in place and maintenance efficiency.

Stakeholder management

Addressing these technological challenges requires an integrated approach to research, development, and implementation of process technologies, in close collaboration with industry, academic institutions, and policymakers. ISPT is equipped to initiate, coordinate, and translate this approach into implemented results in a trustbased environment together with partners.

Our portfolio

We employ a comprehensive strategy that initiates projects that span the entire value chain. Our aim is to bring together relevant stakeholders to promote cooperation between these crucial entities.

Previous projects have yielded significant progress, enhancing our comprehension of the fundamental principles governing drying and measures to reduce energy consumption. In all of our projects, the interaction between industry and academia is key. We aim to realize cost-effective R&D and ensure the effective and rapid transfer of technology from the laboratory to industrial practice.

The impact that we aim for in our Drying and Dewatering Program projects is described in more detail on the project pages of our closed and running ISPT projects (see related projects below).

Partnership with the Dutch Drying Community (NWGD)

Within our program Drying and Dewatering we work in close partnership with the Dutch working society on drying: Nederlandse Werkgroep Drogen (NWGD). We have the joint ambition of innovating the area of drying technology in the Netherlands. NWGD stimulates the development and application of sustainable drying technology by connecting experts, amongst others via networking events.

EuroDrying Conference 2025

ISPT is sponsor for the upcoming EuroDrying conference, from 6-9 July 2025. The conference includes a scientific program with keynote lectures of prominent researchers in the drying community and plenary presentations and poster sessions on cutting-edge research covering a variety of drying-related topics. During this event, ISPT is presenting the projects of the Drying & Dewatering and the Mild Fractionation for Food program. Come visit us at our stand!