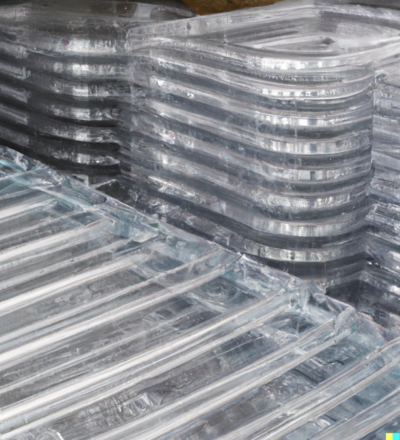

PET trays are a widely used food packaging material. However their recycling remains a challenge due to the mixed composition of materials. CIRCPET has taken a step forward in addressing these challenges by exploring new design solutions and improving the quality of recycled PET (rPET). The project’s findings are laying the groundwork for a fully recyclable PET tray, bringing us closer to circular food packaging.

In short:

- Investigated solutions for 100% PET trays with improved recyclability

- Explored sealing properties of PET-based lidding films for food applications

- Evaluated rPET quality from various post-consumer PET streams

- Provided insights for future research on achieving fully circular PET trays

Destined to grow, difficult to recycle

The demand for PET trays is increasing, but their recycling remains problematic due to material contamination and collection inefficiencies. Current PET trays often combine PET with other polymers, such as LDPE lidding, making it difficult to achieve high-quality rPET. As the availability of bottle-grade rPET declines, it is critical to develop alternative sources for food-grade rPET to ensure a sustainable circular economy.

Achieving circular PET trays

CIRCPET brought together industry and research partners to tackle the recycling challenges of PET trays. The project focused on two key aspects:

- rPET Quality Assessment: Evaluating the potential of post-consumer PET sources for high-quality rPET.

- Tray and Lidding Design: Developing a 100% PET tray.

What did we learn?

The projects results teaches us that:

- A 100% PET lidding film provided a locked seal but did not meet the desired seal strength for industrial applications.

- A lidding film with a PU sealing agent met the required seal strength but was not viable due to the necessary sealing temperature/time combination.

- Research provided critical insights on modifying PET sealing layers for future advancements.

- Magnetic Density Separated PET was found unsuitable for high-quality rPET due to contamination.

- Bottle-sourced rPET (by Wellman) was the only stream deemed suitable for food applications.

- While a fully recyclable PET tray was not achieved within this project, valuable findings have paved the way for a follow-up study to develop a 100% PET tray solution.

- While a fully recyclable PET tray was not achieved within this project, valuable findings have paved the way for a follow-up study to develop a 100% PET tray solution.

To ensure high-quality rPET for food applications, a dedicated collection system might be required. For instance, a deposit or marker system for PET trays. Further research will focus on refining PET sealing layers and optimizing collection methods to enable truly circular PET trays.

Stay involved in our quest for circularity

Join us in in our journey to sustainable packaging by staying up-to-date on project highlights on our LinkedIn page. Explore the Circular Plastics Initiative for more projects, and be a part of the movement towards a greener future.

This is a project of the Circular Plastics Initiative, co-founded by ISPT and DPI.

You might also be interested in

Acknowledgement & partners

The project is partially funded by TKI Groene Chemie en Circulariteit