We work hard on making the industry more sustainable. And we love to tell stories about it.

New project R-ACES helps turn industry clusters into eco-regions

ISPT will start with the new project R-ACES, that emphasizes on industrial waste heat usage in industrial parcs and district heating and cooling (DHC) networks. This project has been granted...

Making a market quality bio-based chemical out of cellulose

Elchin Jafariyeh Yazdi did her research at ISPT’s Cell-U-Value initiative that focuses on the development of sustainable bio-based and sustainable chemicals out of tertiary cellulose.

De waterstofeconomie begint in de industrie

Waterstof moet de systeemdrager worden van de duurzame economie. Maar de weg daar naartoe is lang en loopt waarschijnlijk vooral via de industrie.

Strategy Event Industry 4.0

In December we organized a successful Industry 4.0 Strategy Event in Amersfoort. The interest was high: we had to switch to a larger venue in the centre of Amersfoort. During...

Looking back: building a sustainable future in 2019

It is obvious that 2019 has been an impactful year. Not only for the sustainable process industry, but also throughout society, in the Netherlands and beyond. Below we briefly illustrate some...

PhD student has another research breakthrough

The Probiotics project team of the project Low Energy Living Bacterial Food Formulations celebrated a breakthrough in Evelien Vaessen’s PhD research on Monday the 16th of December. Vaessen had already...

Raising awareness about telecom vulnerabilities

To facilitate the development of strong and healthy organizations, the Institute for Sustainable Process Technology and the Dutch Radiocommunications Agency created the whitepaper Five Steps to Resilience. It offers insight into...

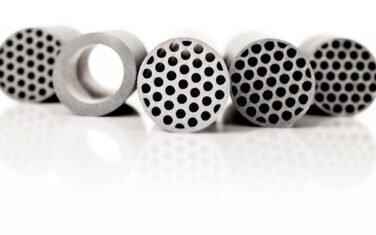

Expanding the boundaries of ceramic membrane separations

Last month Renaud Merlet successfully defended his PhD dissertation. His research was part of one of ISPT’s projects. Background Renaud Merlet was born in France. He finished his Bachelor of...

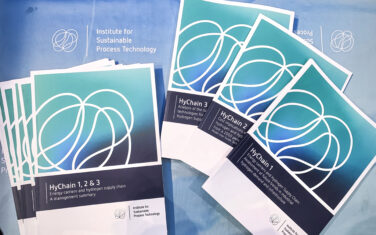

First results of the HyChain project: exploring future hydrogen value chains

Hydrogen plays an important role in the future renewable energy systems. In a large scale sustainable energy system green hydrogen, produced by electrolysis of water, is a crucial element. To increase...

Making the production of food more sustainable

With the ever faster changing consumer demands, the food industry needs to speed up its innovation and production process to become more efficient and more sustainable. To accelerate this, the...

Redesigning our food industry with sustainable process technology

In our program Drying and Dewatering we focus on one of the most important process steps in the food industry: drying.

Can nanofiltration replace energy intensive distillation?

TENMIP (Testing and Evaluation of Nanofiltration Membranes in Industrial Processes) evaluated if nanofiltration can replace energy intensive distillation.

MMIP’s helpen om klimaatdoel 2050 te bereiken

MMIP's geven aan welk maatschappelijk en economisch resultaat de overheid verwacht van duurzame processen. Een interview met Tjeerd Jongsma en Peter Alderliesten.

Dutch consortium aims to make AC motors more efficient

The Institute for Sustainable Process Technology together with Nouryon, Vopak, Semiotic Labs, TPA Adviseurs and the Universiteit Utrecht’s Copernicus Institute have received a grant to develop technology that reduces energy...

Japan shows the way to hydrogen

Andreas ten Cate joined the Hydrogen Innovation Mission to Japan to learn where they stand when it comes to the role of hydrogen in the energy transition.

New large-scale project on Electrically Switchable Adsorption Separation Processes (ELSA)

ELSA is a study about the advantages of Electrically Switchable Adsorption membranes in the industrial separation process.

Development and characterization of Silicon Carbide (SiC) membranes for innovative applications

The separation of oil from stable oil in water emulsions is a challenge. Especially if the limits for oil in water are very low.

Towards a circular economy: the challenge of connecting technology and logistics

The re-use of our materials is essential for a sustainable future. To achieve circularity we need to integrate the whole value chain of waste collection, sorting, recycling and re-use. A...

MaterialenNL: The platform for the Dutch materials field

In view of the wide range and diversity of the materials research field the top sectors Chemistry, HTSM and Energy had the desire to gather all stakeholders at a central...

The road to a green industry: sustainable innovations in our production processes

This is the second blog on how industry is establishing a sustainable future. The first blog introduced the role of industry in several themes which are currently most visible in...

How the industry plays a crucial role in establishing a sustainable future

What if we don't see the industry as a big bad polluter, but as an indispensable partner in building a green future?

The industrial heat pump: analyzing opportunities for the Dutch industry

Het project VERA analyseert de mate waarin de industriële warmtepomp op het moment in Nederland wordt gefaciliteerd.

Fine Biofuels: efficient application for low-value biomass streams

Thewse are the resultas of the Fine Biofuels-project.

A match made in heaven? Workshops series ZERO BRINE matchmaking have started

The ZERO BRINE project is organizing a series of workshops that addresses water re-use and brine stream valorization. The series are aimed at matching brine producers with users of regenerated...