Development and evaluation of tubular and flat porous electrodes for the electrochemical conversion of gasses at ambient temperature.

Motivation

Renewable electricity (RE) generation is currently growing at a rapid pace. Managing demand and supply of electricity is becoming an issue with the intermittent character of RE. Converting electrical energy into chemical energy is an attractive pathway to manage the balance, given the lack of options to store electricity.

Moreover, converting electrical energy into chemical energy enables decarbonisation (or actually recarbonisation) of existing fossil-based chemical production. This decarbonisation occurs when ‘waste’-carbon is built into a chemical product. A technology which uses renewable electricity as the energy source and CO₂ as the carbon source effectively closes the carbon cycle.

Aim

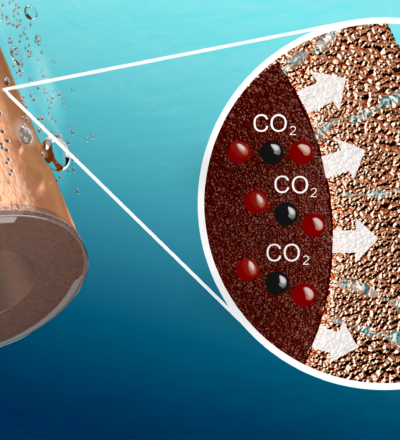

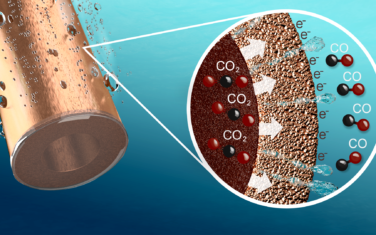

The objective of this project is the evaluation of the tubular electrochemical catalyst concept (‘hollow fibers’, [ref 1]), system development and process evaluation of the hollow fiber as gas diffuser and working electrode (see also figure 1).

Additionally, this project aims at improving the understanding of electrochemical conversion reactions on flat sheet gas diffusion electrodes. The main objectives are summarized as follows:

- Evaluation and explanation of porous, hollow tubes as gas diffuser and electrode, used for both CO2 and NOx conversion

- Improvement and evaluation of gas diffusion electrodes

- Comparison between flat and tubular geometry

- Techno-economic evaluation of porous copper tubes for industrial CO2 conversion

- Design and evaluation of porous tubular electrodes for larger scale application

Approach

The solubility of the reactant (CO2 or NOx) in the liquid-based electrolyte limits the conversion rate of most diffusion based systems. The conversion rate is improved by enhancing the reactant’s mass transport towards the electrode. This project considers enhancement of the conversion rate through a convective supply of reactants and by using flat sheet gas diffusion electrodes.

The convective supply of reactants is achieved by using porous hollow tubes, where the reactant is forced to flow through the porous wall. These tubes, that are acting as gas diffusor and electrode, are evaluated using NOx and CO2 conversion reactions under various conditions (feed flow rate, pH, etc).

The carbon based gas diffusion electrodes are coated with copper in various ways, in order to investigate the effect preparation method on the catalyst’s activity with respect to CO2 conversion.

Additionally, a techno-economic study on the low temperature electrochemical CO2-reduction to CO is performed, to address the required E3C technology improvement in order to reach an economical viable CO-production price.

Furthermore, a stack is designed that allows for simultaneous conversion of gasses on multiple tubes. This stack is tested for its ability to convert CO2 at reasonable current density and power demand.

Publications

References

You might also be interested in

Acknowledgement & partners

This project is co-funded with subsidy from the Topsector Energy by the Ministry of Economic Affairs and Climate Policy.