There’s no getting around it: industry has to start making their chemical processes more sustainable. One promising way to do this is to use electricity instead of fossil fuels to power those processes. The E3C project, which has just wrapped up its work, looked at innovative ways to make this happen.

The overall goal of the project was to pave the way for the use of renewable electricity in the chemical industry and in steel production, in order in turn to cut the CO2 emissions that come from the coal, oil, and gas that now power those processes.

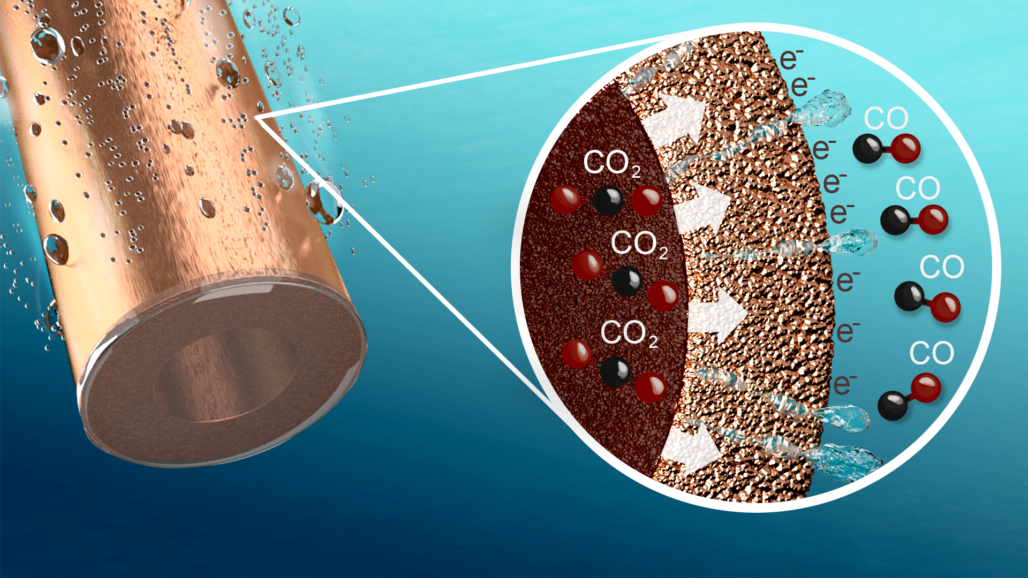

One aim of the E3C project, then, was to develop HFEs further. Now, another advantage of HFEs is that they make it possible to re-use CO2. That could be a big environmental and financial plus for the processing of iron ore, for instance, which needs CO. The CO could be made if CO2 that would otherwise be emitted by the same plant where the ore is being processed were to be captured and passed through HFEs. The same process could even be used to turn CO2 into a raw material for the production of value-added products such as synthesis gas, a mixture of CO and H2 that can be used instead coal-based processes to produce steel. So the same overall innovation has the potential to spawn a range of applications.

But the project team didn’t stop there. They are also worked to enhance the understanding of electrochemical conversion reactions that took place on flat-sheet gas-diffusion electrodes, and to compare the flat and tubular geometries in terms of both technical performance and economic viability. The eventual goal here, of course, is to fine-tune the design of HFEs so they can be used on a large scale in industry.

For this last aspect, the project worked with TNO. And it also worked with industrial partners to explore potential industrial applications of the technology—and not just involving the conversion of CO2: the team also looked into the use of the same technology to convert NOx to ammonia, this time with the use of titanium instead of copper porous tubes.

Naturally, given the complexity of challenges involved, much more work needs to be done to capitalize on the initial gains and roll out HFE designs on an industrial scale. But the project has made important initial strides in this direction, laying the foundations for the tangible results that will no doubt follow.

The E3C project is part of ISPT’s Circular Carbon Program. For more information contact program manager Geoffrey Schouten: or 06 39 12 73 26.

Acknowledgement

This project is co-funded with subsidy from the Topsector Energy by the Ministry of Economic Affairs and Climate Policy.