The DRAGONS Egg project aims to make spray drying processes and the entire powder production chain more efficient (by waste reduction and resource efficiency) with less environmental impact through unravelling the dynamics of drying and agglomeration of the droplets.

In short:

- The DRAGONS Egg project is part of the DRAGONS program and builds on the results from the Energy Efficient Milky Sprays (EEMS) project and the Steering Agglomeration Processes (StAggloP) project.

- This program has the ambition to not only generate scientific knowledge on spray drying, but also to build a predictive tool that allows the transfer of the generated knowledge by the industrial partners to better steer spray drying processes towards optimal agglomeration and high energy efficiency.

- Energy use during spray drying may be reduced with 20% directly, while additional reduction in wasted raw materials can provide even more energy savings (up to 62%).

Drivers for the DRAGONS program

The energy use in the industry due to drying operations is significant and approximately 15% of the total industrial energy use. Energy prices are increasing especially with the current geopolitical situation, driving energy costs for the industry. Therefore, the industry is under heavy pressure to make big steps in increasing process efficiency of dryers. Current energy prices (like in 2022 when they increased by a factor 10 in one year) and highly volatile energy markets make it highly urgent for industry to invest in sustainable solutions to drastically reduce the energy consumption of spray dryers.

The second driver for the DRAGONS program is the high complexity of spray drying process and in particular agglomeration. It calls for a multidisciplinary project approach combining numerical modelling and experimental expertise.

Reducing energy usage during spray drying

The DRAGONS program aims to achieve a 20% reduction in direct energy consumption within industrial spray drying systems. Additionally, it anticipates achieving indirect energy savings through the reduction of material losses, resulting in energy efficiency improvements throughout the entire powder supply chain. To create a breakthrough in the efficiency of spray drying plants, the consortium believes that a better understanding of spray drying and agglomeration processes will enable to develop smart strategies to steer these processes to optimum process efficiency.

DRAGONS program

The DRAGONS program consists of three pillars:

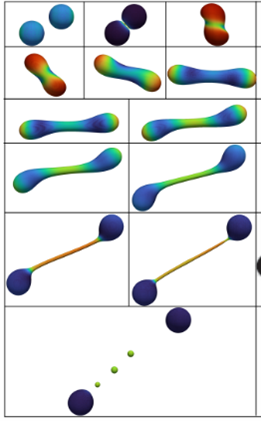

- Individual droplet drying and collisions

- Modelling and testing spray drying and agglomeration at the pilot-scale

- Validation during spray drying at the industrial-scale for which research activities will be carried out starting in the Dragons Egg project, followed by the subsequent project Dragons Hatchling.

In the DRAGONS Egg project, the Technical University of Eindhoven (TU/e), Wageningen University (WUR), and the industrial partners Danone, DSM and FrieslandCampina will continue their advanced numerical modelling and experimental research efforts on spray drying at the droplet scale (first pillar), while the DRAGONS Hatchling project focusses on the pilot and industrial scales (second and third pillar).

Lumped Parameter Model

The final goal of the DRAGONS program is to develop a lumped parameter model to help industrial partners to optimise their industrial-size spray drying processes in terms of process efficiency and product quality and thus facilitate the realization of expected energy savings and CO2 reductions on their sites by the end of the program (i.e. in 2028). In this part of the program, we will focus on gaining fundamental understanding of individual droplet drying and binary collisions. This work is a steppingstone in building the lumped parameter model.

You might also be interested in

Acknowledgement & partners

This project is co-funded by TKI-E&I with the supplementary grant 'TKI- Toeslag' for Topconsortia for Knowledge and Innovation (TKI’s) of the Ministry of Economic Affairs and Climate Policy.