Hydrogen from renewable power sources plays a key role in the energy transition by reducing CO2 emissions related to industrial activity. Hydrogen is contributing as sustainable industry feedstock as well as energy carrier. The ISPT’s Hydrohub Innovation Program is aimed at developing largescale, electrolysis-based production of sustainable and low-cost hydrogen, as a driver for circular industrial chains. Part of this program is the Hydrohub MegaWatt Test Center project for experimentation with full-scale small industrial PEM and Alkaline units of 250 kW each. The project is led by ISPT and consists of Shell, Nouryon, Yara, Gasunie, Frames, Groningen Seaports, TNO, Hanze University of Applied Sciences, University of Groningen and Yokogawa.

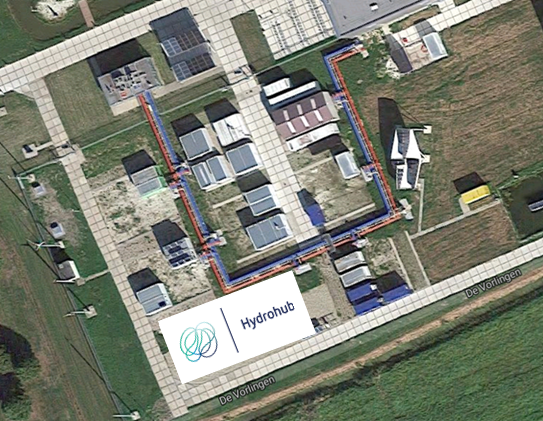

The experimental MegaWatt Test Center is being build this spring at EnTranCe – Centre of Expertise Energy of the Hanze University of Applied Sciences in Groningen. The goal of the project is to run a series of studies to test basic operations, identify the window-of-operation and explore limitations in stress-tests to understand the optimal operation window and limitations of equipment. Another aim is to develop an open-innovation ecosystem in which the MegaWatt Test Center supports further advanced technology development for electrolysis.

Advanced process control

Recently TKI Energy & Industry granted the project with a first addition to the original project. The addition involves advanced process control and will be executed in parallel to the current Hydrohub MegaWatt Test Center. The consortium is happy to announce a new partner in advanced process control: Yokogawa, manufacturer of equipment for the process industry. Production of hydrogen from renewable power sources requires dynamic operation of electrolysers. The new additional, dedicated research project models and researches the impact of variable operation on electrolyser performance and the electricity grid. Optimal control strategies will be developed with the goal to improve overall operational efficiency.

2-3% operational efficiency gain

Advanced process control has been implemented in other industries successfully to improve efficiency and optimize multiple parameters simultaneously by considering the interaction, process dynamics and buffering and release of mass and energy in reactions. In this case of the flexible production of the green hydrogen, this is a totally new way of process control for electrolysers. It is expected that by applying advanced control strategies 2 to 3 % operational efficiency gain can be achieved. The research proposed in this project is aimed to research, model, and test this potential efficiency gain on the PEM unit. Hanze Hogeschool will be responsible to support the field measurements, the hardware and model development. TNO will develop the advanced control model which will be done in an interactive process with the Hydrohub partners.

More information

Are you interested in learning more about the Hydrohub MegaWatt Test Center? Read more or contact Robbert van der Pluijm: r.m.vanderpluijm@summitengineering.nl.

Acknowledgement

Dit project is medegefinancierd door TKI-Energie uit de Toeslag voor Topconsortia voor Kennis en Innovatie (TKI’s) van het ministerie van Economische Zaken en Klimaat