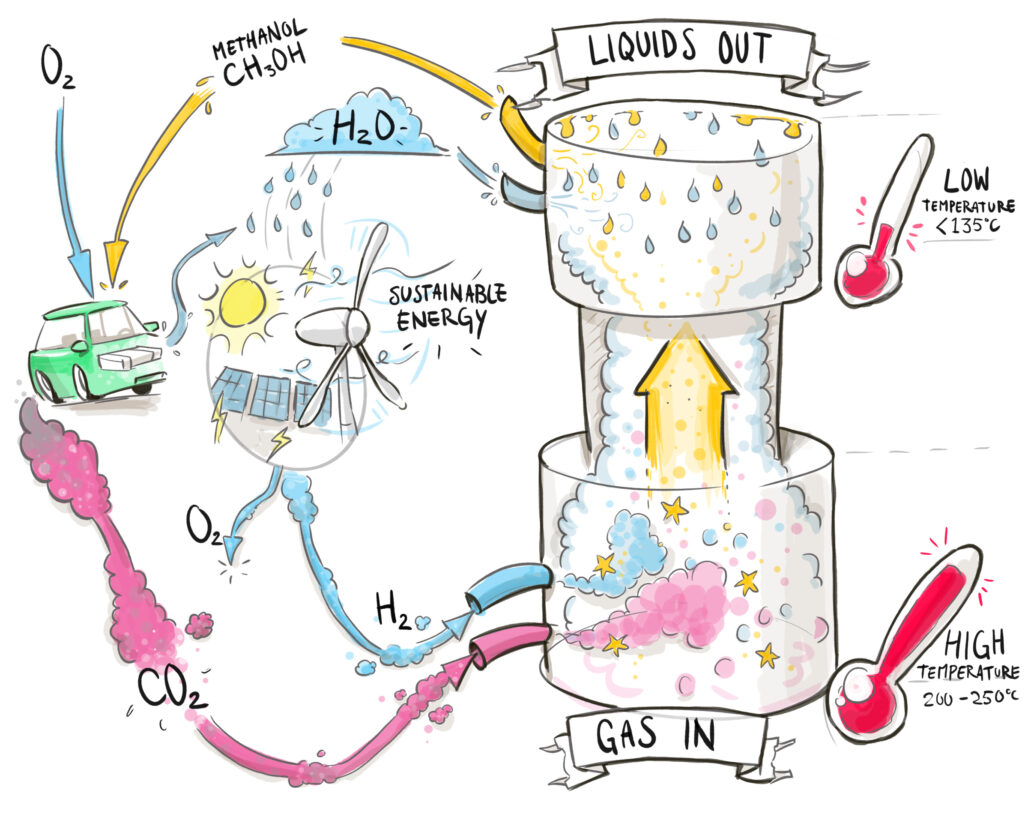

Industry and research stakeholders recently kicked off a broad cooperation, the LOGIC project for the circular production of methanol. Other than the present way of producing methanol from natural gas, the LOGIC (Liquid-Out-Gas-In Concept) reactor produces (liquid) methanol directly from (gaseous) carbon dioxide and hydrogen.

If the hydrogen originates from water electrolysis using renewable electricity, the methanol by the LOGIC process is fully renewable and circular.

Methanol is an important product in the chemical industry, and will become even more important in the transition towards a sustainable economy. It can be used as clean energy carrier, for example as the diesel substituent DME or as versatile feedstock for the chemical industry. Many important base chemicals (such as ethylene or synthesis gas) can be produced from methanol. To date, only a small part of this methanol is produced sustainably, from biomass feedstock (bio methanol). If the carbon dioxide is taken directly from the air or from e.g. biogas upgrading facilities, the LOGIC project enables negative CO2 emissions.

Challenges

The LOGIC reactor relies on internal gas circulation that can be driven by natural convection. The reaction of carbon dioxide and hydrogen to methanol produces the heat that is needed for the whole process, so the process can operate without external heat input. Moreover, more than 99% of the gas input is converted into methanol. The concept is innovative and energy efficient, and promises to become competitive with conventional methanol synthesis.

The reactor, an invention of the University of Twente, has been proven successfully on lab scale. The promising results initiated the broader cooperation of industry and research in the LOGIC project.

The project aims at bringing the reactor towards the level of an industrial-scale demonstration project, within four years. For this purpose, some important technological issues have to be solved. Research will be largely concentrated on the design, operation and testing of a prototype reactor, producing several kilogram of methanol per day. The next step will be scaling up to a hundredfold production level.

Industry and research partners

The Institute for Sustainable Process Technology (ISPT), coordinates the LOGIC project as a part of the Circular Carbon Innovation Program. Partners are University of Twente, DMT Environmental Technology and Royal Dutch Shell.

Read more about the LOGIC project.